You’re staring at a puddle on the garage floor or, worse, smelling that sweet, sickly scent of coolant cooking on a hot engine block. It’s annoying. Usually, the culprit isn't a blown head gasket or a cracked radiator. It’s a tiny, five-dollar piece of metal that we all take for granted until it snaps. We're talking about the 2 inch hose clamps—the literal backbone of automotive cooling, industrial plumbing, and home irrigation.

Most people just head to the hardware store, grab whatever is shiny and fits the diameter, and crank it down until their knuckles turn white. That’s exactly how you strip the gear or, even more likely, slice right through the rubber hose you’re trying to protect. There’s actually a fair bit of engineering hidden in those little circular bands. If you use the wrong material or the wrong tightening mechanism, you’re basically setting a timer for a future leak.

The Anatomy of a Secure Connection

A standard 2 inch hose clamp—often referred to in the industry as a Size 28 or 32 depending on the specific SAE (Society of Automotive Engineers) standard—consists of a band, a housing, and a screw. It sounds simple. But the interaction between these three parts determines if your pool pump stays dry or if your turbocharger piping stays connected under 20 PSI of boost.

Most of what you find at a big-box retailer like Home Depot or Lowe’s are worm gear clamps. These work on a basic principle: the screw has threads that engage with slots cut into the band. As you turn the screw, it pulls the band tight.

But here’s the kicker. Not all stainless steel is actually stainless.

If you see a "Type 201" or "Type 430" stamp, it’s cheap. It’ll look great for a month. Then, the road salt or the humidity in your basement will turn it into a crumbly orange mess. Real pros look for 300-series stainless steel, specifically 304 or 316. Marine environments? You need 316, or the salt air will eat the screw alive while the band stays perfectly fine. That’s a common failure point; manufacturers often use a high-quality band but a cheap, zinc-plated carbon steel screw to save a few pennies.

Why 2 Inch Hose Clamps Strip (And Why You Should Care)

Ever felt that "pop" when tightening a clamp? That’s the sound of the slots in the band shearing off.

It happens because of over-torqueing. For a standard 2 inch worm gear clamp, you generally want between 30 to 50 inch-pounds of torque. Most people use a flathead screwdriver or a nut driver and just guess. If you’re working on a critical system—say, the intake on a diesel engine—guessing is a bad idea.

🔗 Read more: Why Hackers Love Chinese Drama: The Surprising Intersection of C-Drama and Cybersecurity

The Problem with Perforated Bands

Most 2 inch clamps have holes cut all the way through the band. This is the "perforated" style. Under high pressure, the soft rubber of the hose actually squeezes up through those holes. This is called "extrusion." Over time, the vibration of the machine causes those sharp metal edges to saw into the hose.

If you’re dealing with silicone hoses—which are softer and more expensive than standard EPDM rubber—you must use a non-perforated clamp or a clamp with an internal liner. Companies like Breeze or Ideal-Tridon make specialized "Aero-Seal" versions that have a smooth inner liner to prevent this exact type of damage.

Choosing the Right Mechanism for the Job

While the worm gear is the king of the hardware aisle, it isn't the only way to squeeze a 2 inch pipe. In fact, for certain jobs, it's the worst choice.

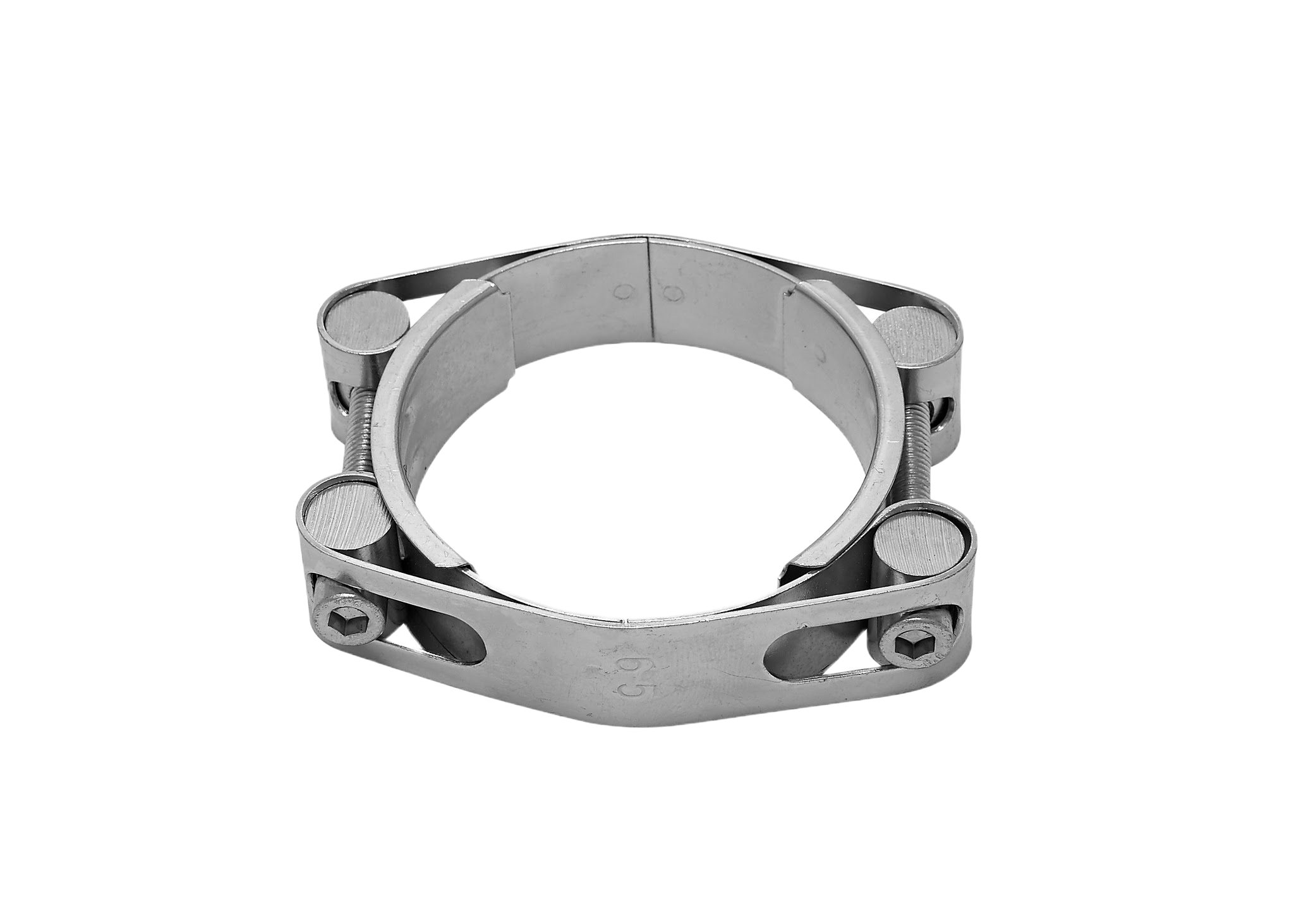

- T-Bolt Clamps: If you’re working with high-pressure applications (like intercooler piping on a car), a T-bolt is the gold standard. Instead of a flimsy band with slots, it uses a solid steel band and a heavy-duty bolt and nut. It provides much more even 360-degree pressure.

- Constant Tension Clamps: These look like a spring. You’ve seen them on factory car radiators. They’re annoying to remove without the right pliers, but they’re brilliant because they expand and contract as the engine heats up and cools down. A worm gear clamp stays the same size, which means when the hose shrinks in the winter, it might leak.

- V-Band Clamps: These are for the heavy hitters. You’ll find these on exhaust systems or turbo housings. They don’t just squeeze the hose; they wedge two flanged pipes together.

Installation Mistakes That Cost Thousands

I once saw a guy try to fix a 2-inch suction hose on a trash pump using two small clamps daisy-chained together because he didn't have a 2-inch one on hand. Don't do that. It creates two "flat spots" where the clamps meet, and it will leak under load.

Another big mistake is placement. You want the clamp about 1/4 inch to 1/2 inch away from the end of the hose. If it’s too close to the edge, the hose can "mushroom" out and slip off. If it’s too far back, it won't be gripping the barbed fitting properly.

The "Double Clamping" Myth

Is two better than one? Sorta. In the marine industry, specifically for any "below the waterline" thru-hull fitting, the ABYC (American Boat and Yacht Council) actually requires double-clamping. But here’s the catch: the hose barb must be long enough to accommodate both clamps. If you jam two clamps onto a short fitting, the second one is just crushing air or, worse, pushing the hose off the barb.

Real-World Specs for 2 Inch Applications

When shopping, you’ll notice the range. A "2 inch" clamp isn't just 2 inches. It usually has a range, like 1-13/16" to 2-3/4".

| Clamp Type | Best For | Typical Material |

|---|---|---|

| Standard Worm Gear | Household plumbing, low-pressure pond liners | 301 Stainless |

| High-Torque Worm Gear | Industrial wash-down hoses | 304 Stainless |

| T-Bolt | Turbochargers, heavy-duty coolant lines | 316 Stainless |

| Constant Tension | Automotive OEM cooling systems | Spring Steel |

Honestly, if you're working on something that matters—like your home's main water shut-off or a vehicle you rely on—spend the extra two dollars for a "Marine Grade" 316 stainless steel clamp. The peace of mind is worth more than the savings.

Troubleshooting Common Leaks

If you’ve got a 2 inch hose clamp installed and it’s still dripping, don’t just tighten it more. You’ll likely break the clamp or the fitting.

First, check the hose. Is it old? Rubber hardens over time (a process called "compression set"). Once a hose gets hard, no amount of clamping force will make it seal. You'll need to cut an inch off the hose to get to fresh, pliable rubber, or replace the whole line.

Second, check the fitting. If you're clamping onto plastic or PVC, be careful. Over-tightening a T-bolt clamp on a plastic flange can actually crack the pipe itself. This is why many industrial plumbers prefer constant torque clamps that have a series of Belleville washers. These washers act like a spring to maintain pressure without crushing the substrate.

Practical Steps for a Leak-Free Setup

Before you reach for the screwdriver, follow these steps to ensure you don't have to do the job twice.

- Measure the Outer Diameter (OD): A "2 inch hose" usually refers to the Internal Diameter (ID). The actual size you need to clamp is the OD, which includes the thickness of the hose walls. A 2-inch ID hose might actually be 2.4 inches on the outside.

- Clean the Barb: Use a wire brush or a rag to remove any corrosion or old rubber bits from the metal fitting. A smooth surface is a sealed surface.

- Check the Screw Head: Use a hex-head nut driver instead of a flathead screwdriver. You’ll get better leverage and won't slip and stab your hand (we've all been there).

- Dry Fit: Slide the clamp onto the hose before you push the hose onto the barb. It sounds obvious, but it’s a pain to realize you forgot the clamp after you’ve struggled to get a tight hose over a fitting.

- Inspect After Heat: If the clamp is on a cooling system, run the engine until it’s hot, let it cool down completely, and then give the screw one tiny extra turn. Materials expand and contract, and that first heat cycle often "seats" the hose.

Choosing the right 2 inch hose clamps isn't about finding the most expensive option; it's about matching the clamp to the environment. If it's a dry, low-pressure situation, the basic zinc-plated stuff from the corner store is fine. But for anything involving chemicals, salt water, or high vibration, moving up to a lined, 316-stainless T-bolt is the only way to ensure you aren't fixing the same leak again in six months.

📖 Related: How Much Is Oura Ring? What Most People Get Wrong About the Total Cost

Check your hoses for "checking" or small cracks near the clamp. If you see them, it’s time to replace both the hose and the clamp. Don't wait for the puddle to tell you there's a problem.