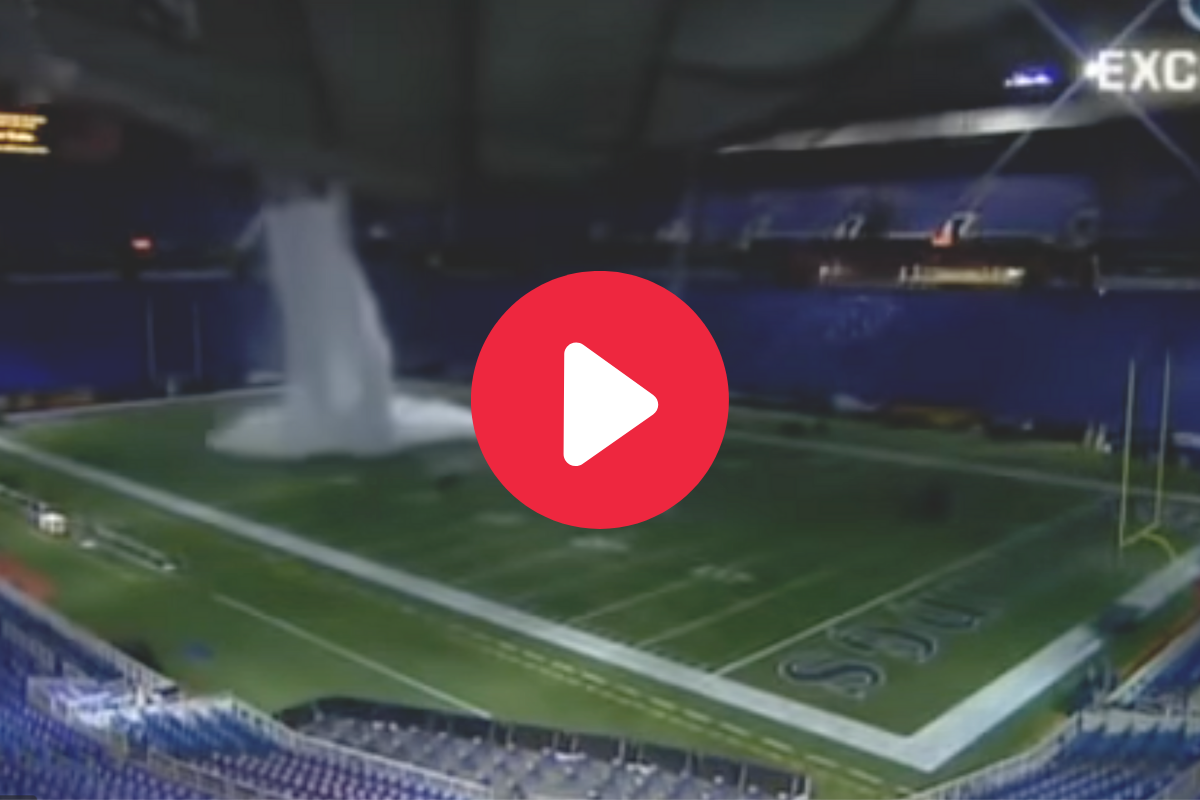

It was 5:00 AM. December 12, 2010. While most of Minneapolis was buried under a thick, suffocating blanket of snow, a few stadium workers were watching security monitors with a growing sense of dread. Then, it happened. The Teflon-coated fiberglass fabric of the Hubert H. Humphrey Metrodome gave way. It didn't just rip; it shredded. Thousands of pounds of snow and ice cascaded onto the turf like a frozen waterfall, caught forever on a grainy, terrifying piece of surveillance footage that would go viral before "going viral" was even a polished term.

The Minneapolis Metrodome roof collapse wasn't just a maintenance failure. It was a cultural "where were you" moment for Minnesotans. For years, the "Dome" was the quirky, air-supported heart of the Twin Cities, a place where the air pressure was so high it practically sucked you out the doors when you left. But that Sunday morning, the pressure escaped. The Vikings were supposed to play the New York Giants that day. Instead, they were looking for a new home.

Why the Metrodome Roof Actually Failed

You can't talk about the collapse without talking about the "Snowmageddon" of 2010. A massive blizzard had dumped over 17 inches of snow on the city. Now, the Metrodome roof was designed to handle snow. It had a sophisticated melting system. Basically, they would pump hot air into the space between the roof's two layers to turn snow into water, which would then run off into a gutter system.

It failed. Why?

Honestly, it was a perfect storm of physics and bad luck. The wind was howling at 30 to 40 miles per hour, which created deep snow drifts. These weren't even distributions of weight. They were massive, heavy piles concentrated in specific valleys of the roof. Steve Maki, the Metropolitan Sports Facilities Commission’s director of facilities at the time, later explained that the sheer intensity of the snowfall outpaced the heating system's ability to melt it. The internal temperature of the dome was cranked up to nearly 95 degrees Fahrenheit to try and melt the accumulation from the inside out. It wasn't enough.

The fabric was old. The Metrodome opened in 1982. By 2010, that outer layer of Teflon-coated fiberglass had survived decades of brutal Minnesota winters, UV exposure, and previous tears. While the stadium authority had performed regular maintenance, the material had naturally lost some of its elasticity. When those specific panels reached their breaking point, they didn't just leak—they disintegrated.

The Chaos of a Relocated NFL Game

Imagine being a New York Giant. You’re stuck in a hotel in a snowed-in city, and you find out your game isn't just delayed—it's moving to a different state. Because the Minneapolis Metrodome roof collapse made the stadium unusable, the NFL had to scramble. They moved the game to Ford Field in Detroit.

🔗 Read more: Charlie Kirk Shooting Investigation: What Really Happened at UVU

It was a logistical nightmare.

The Vikings had to fly out on short notice. The Giants, who were already in town, had to pivot. Fans were left with useless tickets. But the weirdest part? The "home" game for Minnesota was played in a dome belonging to a division rival, the Lions. The Vikings lost 21-3. It was a bleak end to a bleak weekend.

Interestingly, this wasn't the first time the roof had issues. It had actually deflated or suffered damage four times prior: in 1981 (during construction), 1982, 1983, and 1986. But 2010 was different. This wasn't a "sag." This was a catastrophic failure that looked like something out of a disaster movie.

The Engineering Reality of Air-Supported Structures

Most people don't realize that the Metrodome roof was literally held up by air. 20 massive fans kept the 10-acre roof inflated. If the fans stopped, the roof dropped. When the snow ripped the fabric, all that pressurized air escaped instantly.

- The outer layer was only 1/32nd of an inch thick.

- It was held up by 0.03 pounds per square inch of air pressure.

- The total weight of the fabric was about 580,000 pounds.

When you think about it, it's kind of wild we played professional sports under a giant balloon for thirty years.

The Aftermath: From Repair to Replacement

The images of the shredded roof were a turning point. For years, there had been a simmering debate in Minnesota about whether to renovate the Metrodome or build a new stadium. The Vikings' ownership, the Wilf family, had been pushing for a new facility for a long time. The collapse essentially ended the debate.

💡 You might also like: Casualties Vietnam War US: The Raw Numbers and the Stories They Don't Tell You

While they did eventually repair the roof—installing new panels so the stadium could host the 2011 season—the writing was on the wall. The Minneapolis Metrodome roof collapse served as the ultimate proof that the building was obsolete. It was a "Type A" air-supported structure in a climate that demanded something more robust.

In 2012, the Minnesota Legislature finally approved funding for what would become U.S. Bank Stadium. The Metrodome was deflated for the last time in January 2014 and demolished shortly after. If you go to that spot in downtown Minneapolis today, you'll see a massive, jagged, black glass "ship" (U.S. Bank Stadium). It has a fixed roof made of ETFE—a plastic-like material that allows light in but doesn't require air pressure to stay up. It also has a very steep pitch specifically designed to shed snow. Engineers definitely learned their lesson.

Lessons in Urban Resilience

What can we actually learn from this?

First, never underestimate a Minnesota blizzard. Seriously. The 2010 storm was a generational event that broke a building designed specifically for that environment.

Second, infrastructure has a shelf life. We like to think of stadiums as permanent monuments, but they are complex machines. When the Metrodome's roof failed, it was a reminder that maintenance can only go so far when the fundamental design is being pushed past its limits by extreme weather.

Third, the economic impact of a single point of failure is massive. The collapse didn't just affect a football game; it affected local businesses, stadium employees, and the city's branding. It forced a multi-billion dollar conversation that changed the skyline of Minneapolis forever.

📖 Related: Carlos De Castro Pretelt: The Army Vet Challenging Arlington's Status Quo

Moving Forward: Actionable Insights for Large-Scale Maintenance

If you manage a facility or even just a home in a cold climate, the Metrodome story offers some pretty practical takeaways.

Monitor Weight Distribution, Not Just Total Weight

The Metrodome didn't fail because of the average weight of the snow. It failed because the wind created "drifts" that put localized pressure on specific panels. In any structural situation, the "hot spots" are what get you.

Redundancy is Everything

The Metrodome's heating system was its only defense against snow. When that system was overwhelmed, there was no Plan B. In modern engineering, we now see more "redundant" systems where snow can be mechanically removed or shed through gravity alone.

The Cost of "Good Enough"

Patching the roof over the years saved money in the short term but likely contributed to the 2010 disaster. There is a point in the life cycle of any infrastructure where the cost of repair exceeds the value of the security it provides.

Prepare for the "Unprecedented"

We're seeing more extreme weather events globally. The "100-year storm" is happening every ten years. Designing for the "average" is no longer enough; you have to design for the statistical outlier.

The Minneapolis Metrodome roof collapse remains a vivid memory for anyone who lived through it. It was a bizarre, snowy spectacle that marked the end of an era for Minnesota sports. It taught us that no matter how much air you pump into a project, nature always has a way of letting the air out.

Next Steps for Further Research:

- Review the structural engineering reports from the 2010 Metropolitan Sports Facilities Commission to understand the specific tear patterns of the fiberglass.

- Compare the ETFE roof specifications of U.S. Bank Stadium with the original Teflon-coated fiberglass of the Metrodome to see how snow-load calculations have evolved.

- Watch the original footage of the collapse—it's still available through various news archives and remains one of the most significant examples of structural failure caught on camera.