You’re staring at a mess of lines. Some are thin, some are thick, and honestly, if you aren't a Master Tech, an abs brake system diagram usually looks like a bowl of electric spaghetti. But here’s the thing. Your Anti-lock Braking System is probably the only thing standing between a controlled stop and a very expensive date with a guardrail when the roads get greasy.

It’s not magic. It's just physics managed by a computer that thinks way faster than you do.

When you hit the brakes on ice, your wheels want to stop turning. If they stop turning while the car is still moving, you’re skidding. You’ve lost steering. You’re a passenger in a two-ton sled. The ABS prevents this by "pumping" the brakes—sometimes up to 15 times per second. To understand how that happens, you have to look at the blueprint.

What the ABS Brake System Diagram Actually Shows You

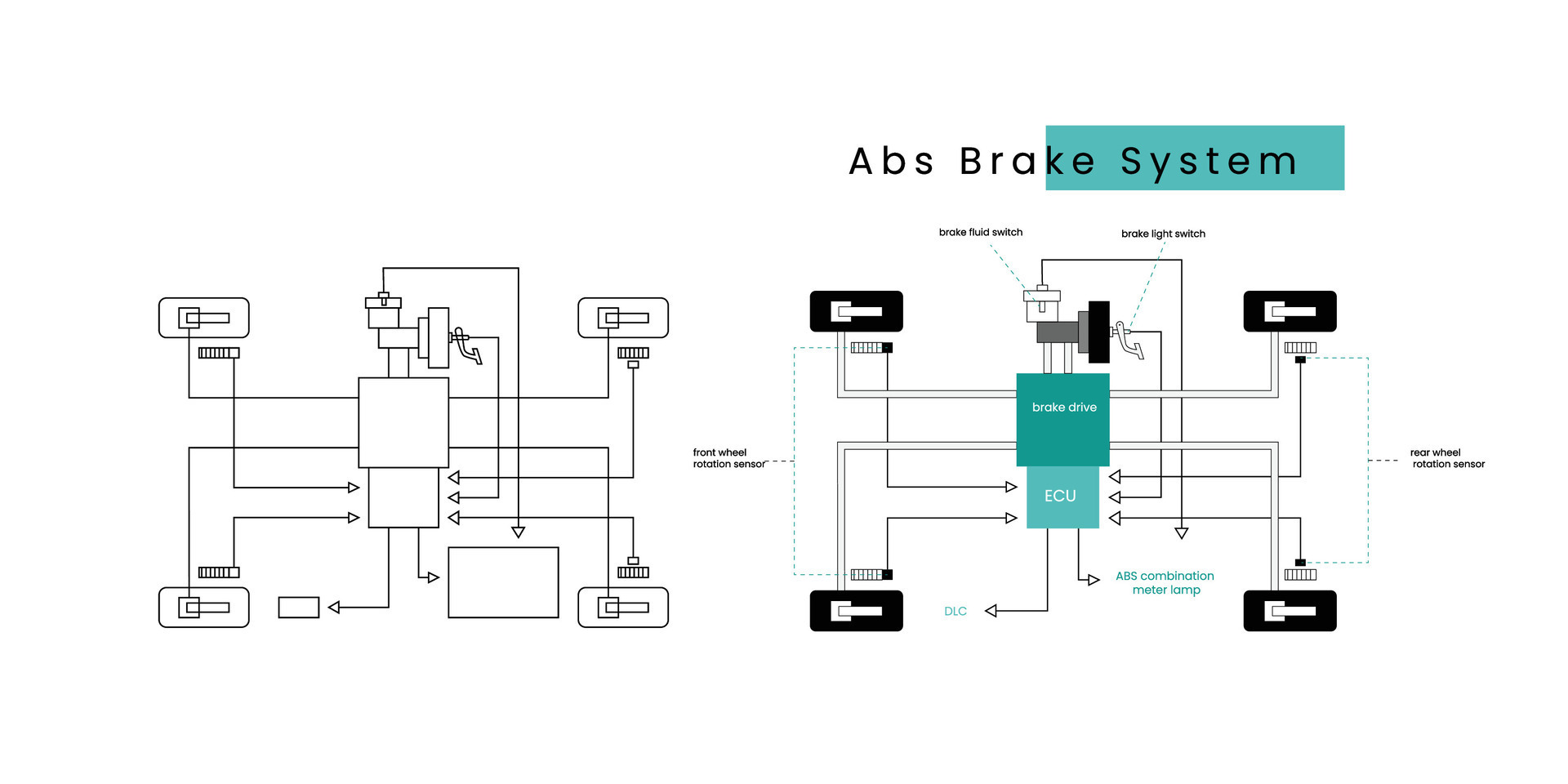

If you look at a standard schematic from a manufacturer like Bosch or Continental—the giants who actually build these things for Ford, Toyota, and BMW—you’ll notice three distinct "layers."

First, there’s the electronic layer. This is the brain stuff. You'll see the ABS Control Module (often called the EBCM or Electronic Brake Control Module). This is the boss. It’s a computer that sits on top of a pump. On your abs brake system diagram, you’ll see wires running from this module to each wheel. Those are your speed sensors.

Then you have the hydraulic layer. This is where the fluid lives. Lines run from the master cylinder—that’s the thing under your hood connected to your brake pedal—into the ABS modulator valve assembly. From there, separate lines go out to each individual wheel.

The third layer is the mechanical bit at the wheels. This is the hardware. We’re talking about the tone rings (those notched circles that look like gears) and the actual calipers.

Most people get confused because they think the ABS applies the brakes. It doesn’t. In most situations, it actually releases them. When the sensor tells the computer "Hey, the front left wheel just stopped spinning but we're still doing 50 mph," the computer opens a tiny valve to drop the pressure on that one wheel. It lets the wheel spin again. Then it closes the valve to let the pressure back in. Over and over.

The Parts You'll Spot on the Map

The Speed Sensors (The Eyes)

On any decent abs brake system diagram, you'll see four sensors. They are Hall-effect sensors or variable reluctance sensors. Basically, they use magnets to "count" how many teeth on a gear pass by every second. If one sensor suddenly reports "zero" while the others are reporting "sixty," the ABS kicks in. These are the most common failure points. A bit of road salt or a stray wood chip can gunk up the sensor, and suddenly your ABS light is glowing like a jack-o'-lantern.

The Modulator Valve Block (The Heart)

This is the big aluminum block with all the metal tubes coming out of it. Inside are solenoid valves. If you see "Inlet Valve" and "Outlet Valve" on your diagram, that's what we're talking about.

- Normal Mode: The valves are open; your foot does the work.

- Dump Mode: The system detects a skid and opens an outlet valve to bleed off pressure into a tiny reservoir.

- Increase Mode: The pump kicks on to shove fluid back toward the wheel to grab the rotor again.

The Pump Motor

You’ve felt this. It’s that vibrating, grinding sensation under your foot when you slam the brakes on a wet road. That’s the pump. Because the system "dumps" fluid to stop a skid, it needs a way to get that fluid back into the lines. The pump is the muscle.

Why Modern Diagrams Look Different

Ten years ago, an abs brake system diagram was fairly simple. Today? Not so much. Now we have Stability Control (ESC), Traction Control (TCS), and even Emergency Brake Assist (EBA).

These systems all use the same hardware.

🔗 Read more: Why Checking a Geiger Counter World Map is More Addictive Than You’d Think

If your car has Electronic Stability Control, the diagram will show an additional "Yaw Sensor" and a "Steering Angle Sensor." The car needs to know not just how fast the wheels are turning, but which way you’re pointing the steering wheel and if the car is actually sliding sideways. If the car feels you turning left but the yaw sensor says the car is still heading straight (understeer), the ABS module will pulse the inside rear brake to pivot the car. It’s incredibly smart.

Diagnosing the "Christmas Tree" Dash

When the ABS light comes on, the system usually shuts itself off. You still have brakes, but you have 1970s-style brakes. No anti-lock. No stability control.

Don't just start throwing parts at it. Use the diagram to trace the likely culprit.

If the diagram shows that all four sensors ground at a single point on the chassis (often labeled G101 or similar), and you have codes for all four sensors failing at once, you don't have four bad sensors. You have one rusty bolt. Understanding the ground paths on an abs brake system diagram can save you $800 in unnecessary parts.

Also, look for the "fused power" lines. The ABS pump draws a massive amount of current. Usually, there's a big 40-amp or 60-amp fuse in the under-hood box. If that’s blown, the pump won't run, and the system will throw a "Pump Circuit Malfunction" code.

Dealing with the Hydraulic Side

Replacing a sensor is easy. Dealing with the modulator is a nightmare.

If your abs brake system diagram shows a "closed loop" system, bleeding the brakes isn't as simple as pumping the pedal. Air can get trapped inside those tiny solenoid valves. You often need a bi-directional scan tool to tell the computer, "Hey, open all the valves so I can flush the air out."

If you try to do it the old-fashioned way, you might end up with a "mushy" pedal that never feels quite right.

Practical Steps for the Home Mechanic

If you're trying to fix an ABS issue using a diagram, here is the smart way to move forward.

First, get a dedicated OBD-II scanner that can read ABS codes. A generic $20 scanner won't do it; you need one that talks to the chassis modules. Write down the codes.

Next, locate your specific abs brake system diagram for your year, make, and model. Don't use a generic one. Use a service like AllData or a Haynes manual.

Check the "Tone Rings" first. Look at the diagram to see where they are located—usually pressed onto the CV axle or integrated into the wheel bearing. If a ring is cracked, it sends a "pulsed" signal that confuses the computer. It looks like a mechanical failure but shows up as an electronic code.

Finally, check your wiring harness. Most ABS "failures" are actually just a broken wire near the wheel well where the cable has to flex every time you turn or hit a bump. Use your diagram to find the wire colors (e.g., "Green with White Stripe") and test for continuity with a multimeter.

Understanding the layout isn't just about being a nerd. It’s about knowing exactly where the signal stops so you aren't guessing with your safety. Once you can trace the path from the sensor to the module and back to the pump, you’ve mastered the system.

Check your brake fluid level. Seriously. Many ABS modules will throw a fault code if the fluid is just slightly low because it can't maintain the pressure required for the "Increase Mode" of the pump. It’s the simplest fix on the map.