You’re standing on a dock or maybe a construction site, looking at a heavy engine or a crate that weighs about as much as a small car. If you tried to lift it straight up, your spine would basically turn into gravel. But then you see it—a series of ropes looped through a couple of metal housings. With one hand, a guy pulls the rope, and that massive weight just... rises. It looks like a magic trick. Honestly, it kind of is. That’s the pulley block and tackle in action, a piece of technology so old that Archimedes was using it to pull entire ships onto the shore by himself back in 250 BC.

Physics doesn't care about your gym PR. It cares about leverage.

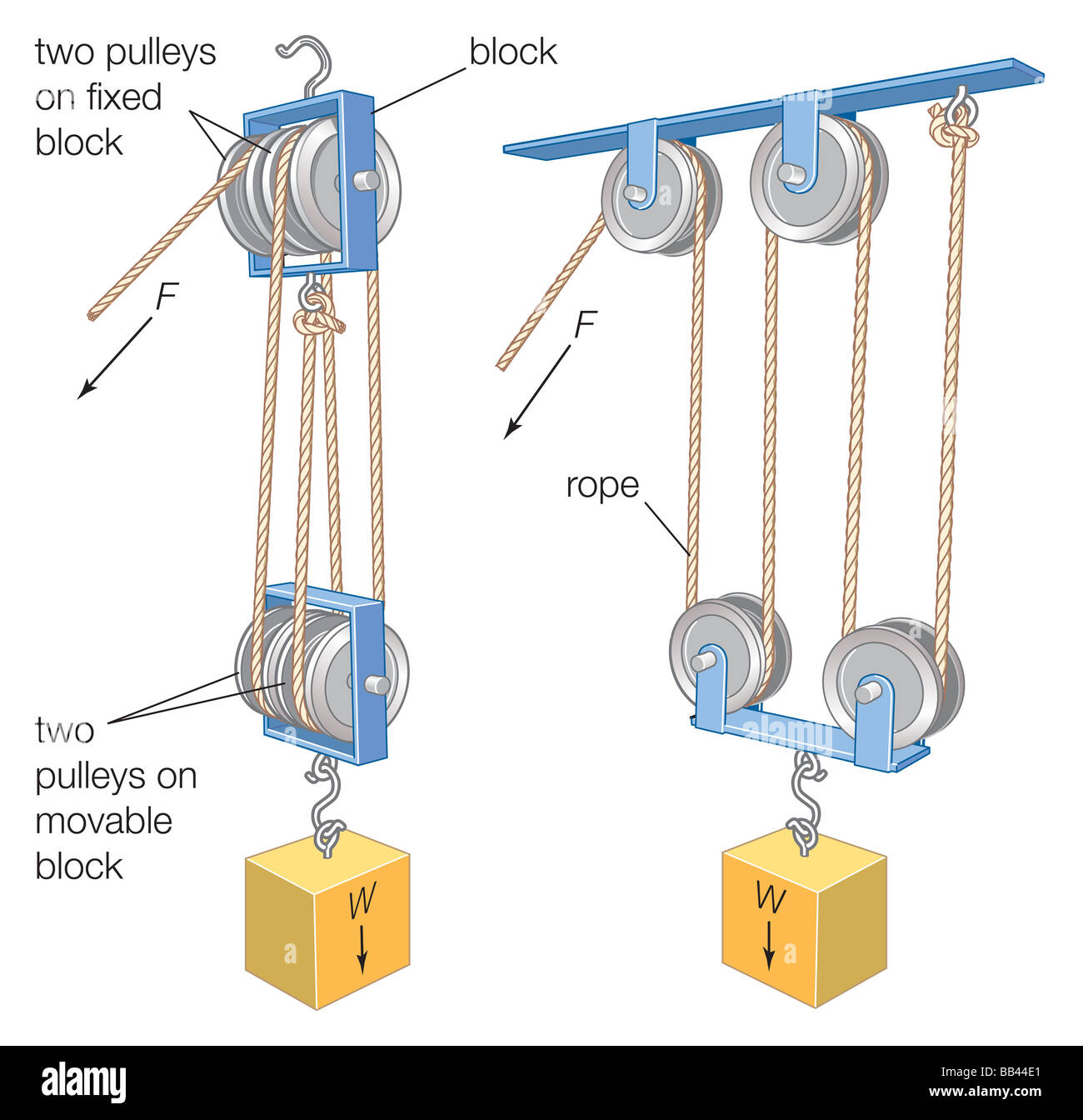

Most people think of a pulley as just a wheel on a stick. That’s a "fixed pulley," and while it’s great for changing the direction of a pull (like on a flagpole), it does zero for your actual lifting power. To get the real "superpower" effect, you need a block and tackle. This is a system of two or more pulleys—the "blocks"—with a rope or cable—the "tackle"—threaded between them. By trading distance for force, you can move mountains.

💡 You might also like: Finding the Perfect Picture of Tik Tok for Your Profile and Why It Matters

How the Physics Actually Works (Without the Boring Textbook Talk)

Basically, every time you loop that rope back and forth between the fixed block (the one attached to the ceiling or a beam) and the moving block (the one attached to the load), you’re adding "parts of line." If you have four ropes going up from the load, you’ve just divided the weight of that load by four. That’s a 4:1 mechanical advantage.

Math time, but quick: If you’re lifting 400 pounds with a 4:1 system, you only feel like you’re pulling 100 pounds.

There is a catch, though. There’s always a catch. You have to pull that rope four times as far. To lift the crate one foot off the ground, you’ve got to haul four feet of rope through your hands. It’s a trade. You give up speed and distance to gain raw, unadulterated strength. People get frustrated when they see a huge coil of rope and realize they’ve been pulling for two minutes just to move a generator a few inches. But hey, it beat calling a tow truck.

The Real-World Components You’ll Find in a Professional Kit

If you go to a shop or browse an industrial catalog, you aren't just looking for "a pulley." You’re looking for specific gear that won't fail and drop a grand piano on your head.

- The Shell: This is the outer "case" of the block. In the old days, these were beautiful chunks of ash or elm wood. Today, they’re usually galvanized steel or high-grade aluminum.

- The Sheave: Pronounced "shiv." This is the actual wheel inside. A good sheave has a deep groove to keep the rope from jumping out.

- The Bearing: This is where the cheap stuff fails. High-end blocks use ball bearings or bronze bushings to reduce friction. If your block squeaks like a dying bird, you're losing force to heat and friction.

- The Becket: This is just a fancy name for the little metal eyelet at the bottom of a block where you tie off the end of the rope.

I’ve seen people try to rig a pulley block and tackle using hardware store clothesline pulleys. Don't do that. Those are designed for wet socks, not engines. If the sheave isn't rated for the load, it can shatter, sending shards of metal flying. Always look for the Safe Working Load (SWL) stamped right on the side of the metal.

💡 You might also like: Why the Apple Laptop 13 Inch MacBook Pro is the Weirdest Computer You Might Still Want

Friction: The Silent Thief of Your Gains

In a perfect physics world, a 6-pulley system gives you a 6:1 advantage. In the real world, the world where we actually live, friction exists. Every time the rope bends around a sheave, you lose a little bit of energy. By the time you get to an 8:1 or 10:1 system, the friction can become so high that you’re working harder just to move the rope than you are to move the load.

Experienced riggers usually stop at a 4:1 or 6:1 for manual lifting. If you need more than that, you don't add more pulleys; you get a winch or a motorized hoist.

Different Flavors of Rigging

You’ll hear sailors and crane operators use weird terms. A "Gun Tackle" is the simplest version—two single-pulley blocks. It was used to move cannons on old warships. Then you’ve got the "Luff Tackle" (a double block and a single block) and the "Twofold Purchase" (two double blocks).

The most common one you'll see in modern construction is the square-drop or tandem setup. This is where the sheaves are side-by-side rather than one on top of the other. It keeps the blocks from twisting and tangling the ropes, which is a total nightmare when you're 50 feet in the air.

Why We Still Use This in the Age of Hydraulics

We have electric winches. We have hydraulic pistons that can crush cars. So why is the block and tackle still everywhere?

- Reliability: It doesn't need a battery. It doesn't leak oil. It doesn't care if it gets rained on.

- Precision: You have an incredible amount of "feel." If you’re lowering a delicate glass panel, a manual tackle lets you move it millimeter by millimeter.

- Portability: You can throw a 4:1 block and tackle and 50 feet of synthetic rope into a backpack. Try doing that with a hydraulic jack.

I remember helping a friend move a heavy lathe into his basement workshop. The stairs were tight, and there was no way to get a forklift in there. We rigged a block and tackle to a structural beam, backed a truck up, and basically "walked" the machine down the ramp. It was silent, controlled, and cost us exactly zero dollars in fuel.

The Safety Check That Most People Skip

Before you pull that rope, look at the "lead line"—that’s the part of the rope you’re actually holding. Is it rubbing against the side of the block? That’s called "chafing," and it’ll saw through a nylon rope faster than you’d think.

Also, check your "standing part"—the anchor point. Your pulley system might be rated for 2,000 pounds, but if you’ve hooked it to a rusty eye-bolt in a rotten 2x4, the whole ceiling is coming down. The anchor has to be stronger than the load plus the force you're applying.

💡 You might also like: The Seabrook Station Reality: What Most People Get Wrong About the Nuclear Power Plant in NH

Actionable Steps for Using a Pulley Block and Tackle

If you’re looking to add one of these to your garage or job site, don't just wing it.

- Calculate your needs: Weight of the object / Your pulling strength = Number of lines needed. If the object is 600 lbs and you can comfortably pull 100 lbs, you need a 6:1 system.

- Choose the right rope: Use "low-stretch" polyester or static kernmantle rope. Dynamic climbing rope is too bouncy; it’ll act like a giant rubber band and make the load jump dangerously.

- Inspect the sheaves: Spin the wheels. They should spin freely without any side-to-side wobble. If they feel "gritty," the bearings are shot.

- Check the "Fleet Angle": Ensure the rope is entering the pulley straight. If it enters at an angle, it will wear down the "cheeks" (the sides) of the block and eventually jam.

- Lubricate correctly: Use a dry PTFE spray or graphite. Avoid heavy grease that attracts dirt and sand, which acts like sandpaper on your rope.

The beauty of the pulley block and tackle is its honesty. It's just simple geometry working in your favor. Whether you're clearing a fallen tree from a trail or tensioning a zipline, understanding how to rig these blocks is a foundational skill that turns a "this is impossible" moment into a "let me get my gear" moment.

When you get your first set, practice with something light. Get a feel for how the rope stacks in the blocks. Once you see that heavy load hover in the air with minimal effort, you'll never look at a piece of rope the same way again.