Honestly, if you look around your room right now, you’re staring at a world built on stuff that isn't metal. We obsess over "Iron Ages" and "Bronze Ages," but we’re basically living in the Age of Polymers and Ceramics. When people ask what are non metallic materials, they usually expect a dry chemistry definition about electrons. Boring. In reality, we’re talking about the carbon fiber in a supercar, the silicon chip in your pocket, and the glass fiber cables buried under the ocean that let you read this.

It’s easy to define them by what they aren't. They don't have that metallic luster. They don't bend like a copper wire—they usually snap or stretch. But that’s a lazy way to look at it. Non-metallics are the thermal shields that keep astronauts from turning into toast on re-entry. They’re the insulators that keep your house from burning down when you plug in a toaster. Without them, electricity is just a wild, uncontrollable spark.

The Chemistry of Why They Don't Act Like Iron

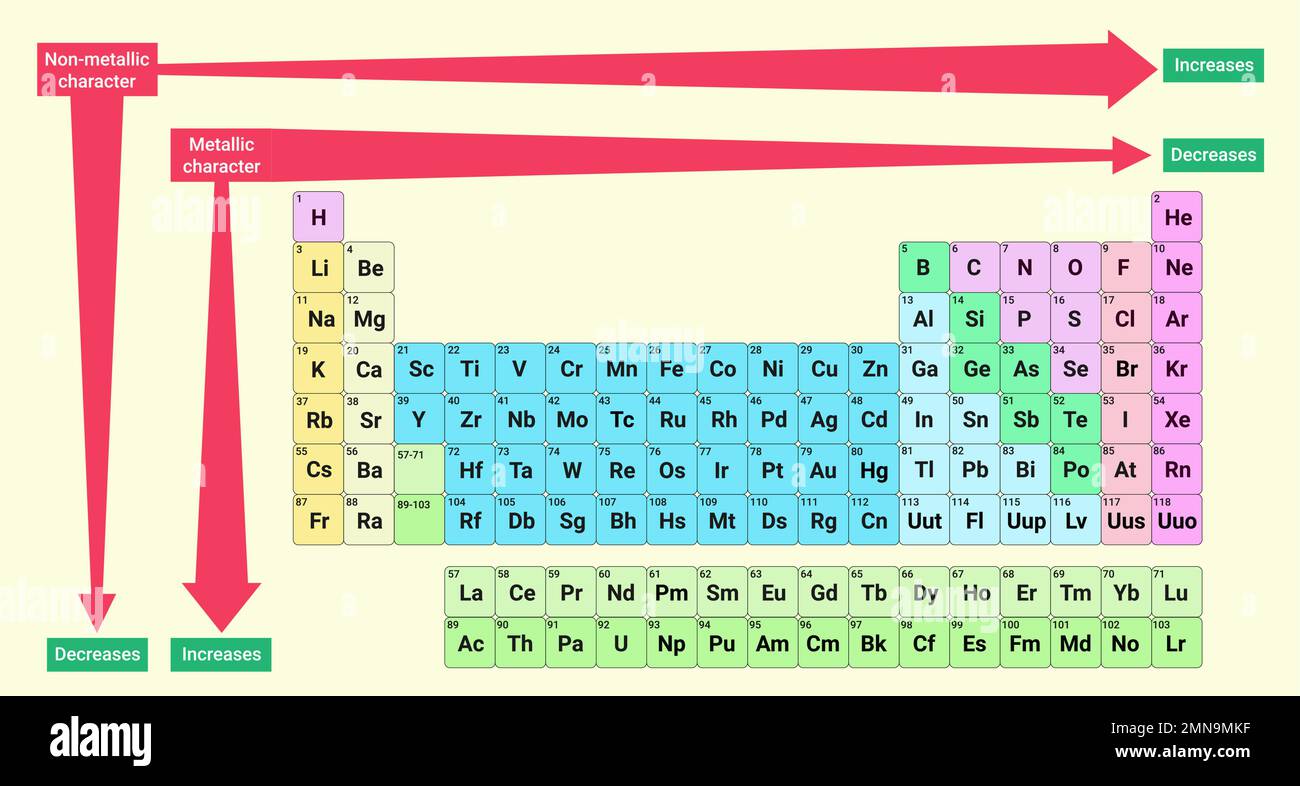

To get why these materials matter, you have to look at their "glue." Metals share a "sea of electrons." It's a big, communal pool that lets heat and electricity zip around easily. Non-metals? They’re stingy. They use covalent or ionic bonding. They lock their electrons down tight.

This tightness is exactly why what are non metallic substances—like diamond or sulfur—behave so differently. Because their electrons aren't free to roam, most non-metals are terrible at conducting electricity. But that "weakness" is their greatest superpower. It makes them the ultimate gatekeepers of energy.

👉 See also: What to Do With a Raspberry Pi: Why Your First Project Usually Fails (And What to Build Instead)

Take Graphite versus Diamond. Both are just carbon. That’s it. But because of how those carbon atoms are arranged, one is so soft it rubs off on paper, and the other can drill through solid rock. It’s wild how the same "non-metallic" element can be both a lubricant and the hardest natural substance on Earth.

Polymers: The Shape-Shifters

When we talk about non-metallics in 2026, we’re mostly talking about polymers. Plastics. Composites. These are the workhorses of the global economy.

Think about Boeing’s 787 Dreamliner. Over half of that massive bird is made of composite materials—mostly carbon-fiber-reinforced plastic. Why? Because it’s lighter than aluminum but stays incredibly stiff. It doesn't rust. It doesn't "fatigue" the same way metal does after thousands of flights. If you tried to build that plane out of traditional steel, it would be too heavy to get off the tarmac efficiently.

- Thermoplastics: These are the recyclables. You heat them up, they melt, you shape them. Think Polyethylene (PE) or Polypropylene (PP).

- Thermosets: These are "one and done." Once they set, they stay. Epoxies used in circuit boards are the classic example. You can’t melt them back down; they’ll just char.

- Elastomers: This is your rubber. Natural or synthetic. It's the only reason your car stays on the road when you take a corner at 60 mph.

Ceramics and Glass: More Than Just Your Coffee Mug

Ceramics are the grumpy old men of the material world. They’re brittle, they hate being dropped, and they’ve been around forever. But they can handle heat that would turn a steel beam into a wet noodle.

Modern engineering uses technical ceramics like Silicon Carbide (SiC) and Alumina ($Al_{2}O_{3}$). You’ll find these in high-performance brake discs for racing cars or as armor plating for military vehicles. They are insanely hard.

And then there's glass. We take it for granted, but it's a non-metallic marvel. Fiber optics—essentially long, thin strands of extremely pure glass—carry almost all of the world's internet data. It’s faster and carries more bandwidth than any copper cable ever could. We’ve moved from "looking through" glass to "communicating through" it.

The Silicon Exception

Silicon is the weirdo. It’s a metalloid, but for the sake of understanding what are non metallic foundations of technology, it's the king. It lives in that gray area. It’s not a great conductor, and it’s not a great insulator. It’s a semiconductor.

By "doping" silicon with tiny amounts of other elements like Boron or Phosphorus, we can control exactly how it moves electricity. This tiny bit of non-metallic chemistry is the reason you have a smartphone. Every CPU, every GPU, and every flash drive relies on the fact that silicon is "kinda" metallic but mostly not.

Real-World Limitations and the "Brittle" Problem

It’s not all sunshine and roses. Non-metals have a massive Achilles' heel: fracture toughness.

If you hit a piece of steel with a hammer, it dents. It absorbs the energy by deforming. If you hit a ceramic plate or a piece of glass with a hammer, it shatters. This lack of ductility is why we still use metals for the "bones" of skyscrapers and bridges. We need materials that give us a warning (by bending) before they fail. Non-metals tend to fail catastrophically and without warning.

However, we’re getting better at fixing this. Material scientists are now "toughening" ceramics by embedding fibers inside them, creating Ceramic Matrix Composites (CMCs). It’s essentially the same logic as putting steel rebar in concrete.

The Sustainability Crisis

We can't talk about non-metallics without mentioning the elephant in the room: waste. Metals are easy to recycle. You melt a soda can, and you get aluminum back. It’s a closed loop.

Non-metallics, especially complex polymers and composites, are a nightmare. Most "recycled" plastic is actually "downcycled" into lower-quality products like park benches or carpet fibers. It doesn't go back to being a high-end water bottle. And carbon fiber? Once it’s cured, it’s incredibly hard to reclaim those fibers without destroying their strength.

There's a massive push right now toward bio-based non-metallics. We’re seeing plastics made from corn starch or seaweed, and resins that can actually be dissolved and reused. It’s not just a "green" trend; it’s a necessity for the supply chain.

Actionable Steps for Choosing Materials

If you're working on a project—whether it's a DIY home repair or a product design—choosing between metallic and non-metallic is your first big hurdle.

- Check the Thermal Profile: If the environment hits over $1000^{\circ}C$, forget most metals and plastics. You need technical ceramics or specialized refractories.

- Weight vs. Stiffness: If you need something to be rigid but light (like a drone frame), carbon fiber composites win every time. Just be prepared for the cost; non-metallic high-performance materials are rarely cheap.

- Electrical Isolation: Never assume. While most non-metals are insulators, "black" plastics often contain carbon black, which can actually be slightly conductive. Always test with a multimeter if safety is on the line.

- Chemical Environment: Metals hate salt and acid. If you’re building something for the ocean, go for high-density polyethylene (HDPE) or specialized fiberglass. They’ll outlive stainless steel in salt water by decades.

The world is moving away from the heavy, "dumb" metals of the past. We’re entering an era of smart, engineered non-metallics that are lighter, tougher, and more specialized. Understanding the difference isn't just for chemists anymore—it's for anyone trying to navigate a world built on silicon and carbon.

📖 Related: HP Printing Ink Cartridges: Why They’re So Expensive and How to Actually Save Money

Next Steps:

Identify the high-stress components in your current project. Evaluate if switching from a metallic to a composite material would reduce weight or improve corrosion resistance. Research local specialized recycling facilities if you are working with large quantities of thermoset plastics or fiberglass to minimize environmental impact.