You’re standing on a factory floor in 1980. It’s loud. It’s oily. Every single movement of a lathe or a mill is dictated by a machinist’s intuition and a set of manual handwheels. If that machinist has a bad morning or a second cup of coffee that makes their hands shake, the part is scrap. Fast forward to now. We have software doing the "thinking," but it’s not just about replacing hands with robots. When people ask computer aided manufacturing offers which possible benefits, they usually expect a dry list of "efficiency" and "speed." Honestly? It’s way deeper than that.

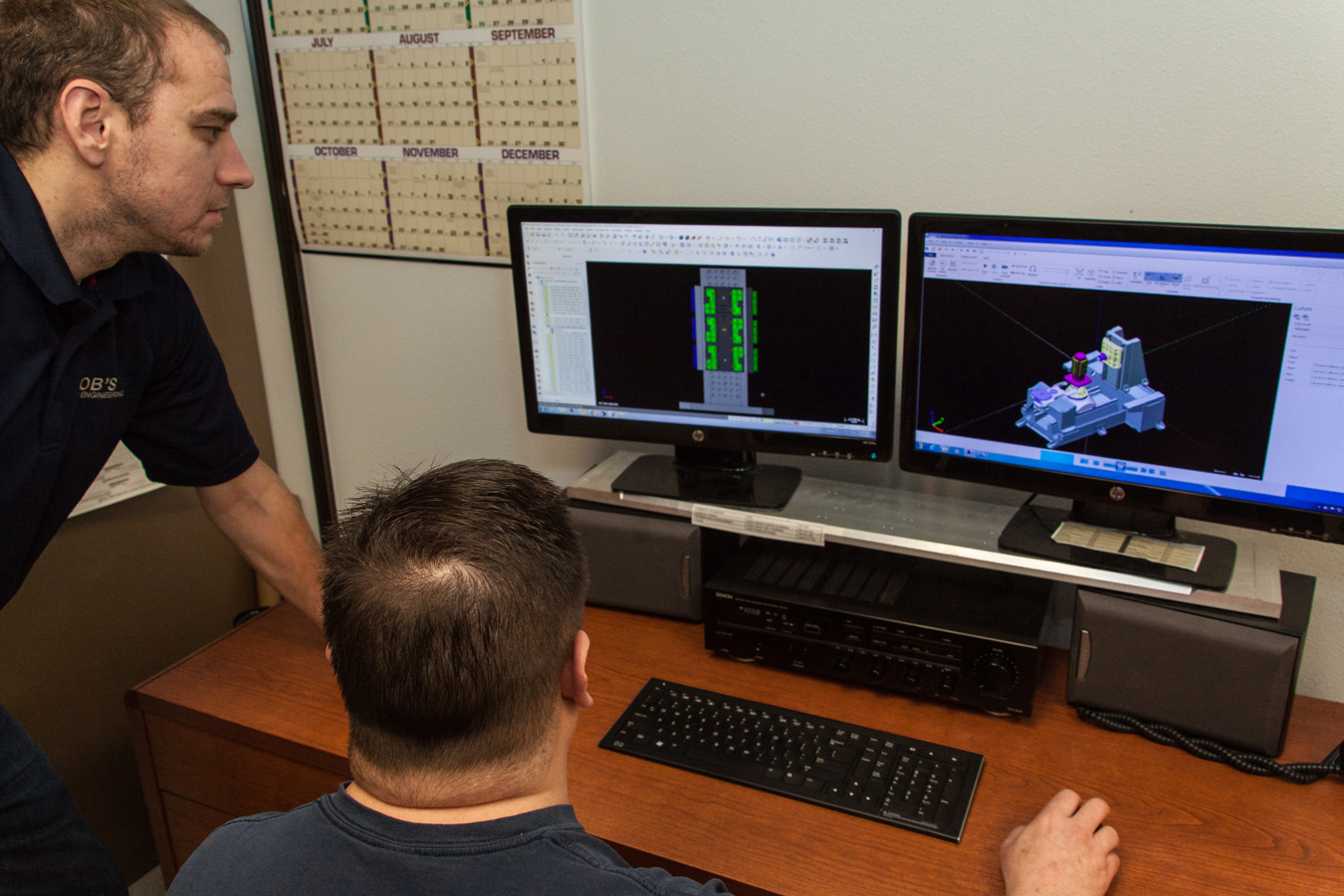

CAM is basically the bridge. It’s the translator that takes a beautiful 3D model from CAD (Computer-Aided Design) and turns it into a language a machine understands—usually G-code. Without this bridge, that 3D model is just a pretty picture. With it, you get a level of surgical precision that makes manual machining look like carving stone with a spoon.

The Massive Leap in Precision and Repeatability

Precision is the big one. If you’re making a bracket for a shelf, maybe a millimeter doesn't matter. If you’re making a turbine blade for a GE Aerospace engine, a millimeter is a catastrophe. CAM software eliminates the "human "variable. Once the toolpath is set, the machine executes it perfectly. Every. Single. Time.

You’ve got to think about the complexity too. Try hand-cranking a 5-axis simultaneous milling operation. You can’t. It’s mathematically impossible for a human to coordinate those movements in real-time. CAM makes "impossible" geometries—like the internal cooling channels in a 3D-printed rocket nozzle or the organic curves of a medical implant—standard procedure. Companies like Autodesk (Fusion 360) and Mastercam have built entire empires just on the ability to calculate these paths so the tool doesn't snap and the part doesn't explode.

Waste Not, Want Not: Material Savings

Raw materials are expensive. Titanium, inconel, or even high-grade aluminum can eat your margins if you're turning half of it into chips on the floor.

One of the most underrated answers to computer aided manufacturing offers which possible benefits is "nesting." Think of it like Tetris. If you have a massive sheet of metal and you need to cut out 50 different parts, a human might get 60% yield. CAM software runs algorithms to pack those parts so tightly that you might hit 85% or 90% yield. That 25% difference? That’s pure profit. It’s also just better for the planet. Using less stuff is the easiest way to be "green" without trying too hard.

The "Digital Twin" and Avoiding the Big Crash

Machines are fast now. A modern CNC spindle can move at speeds that would blur your vision. If there’s an error in the code—say, the tool tries to pass through a steel vice at 500 inches per minute—you aren't just breaking a tool. You’re potentially looking at a $50,000 repair bill and weeks of downtime.

Simulation is the secret sauce.

Before a single chip is cut, the CAM software runs a digital simulation. It’s a virtual "dry run." You see the tool move, you see the material disappear, and most importantly, the software screams at you if there’s a collision. It’s basically an insurance policy written in code. Modern shops don't just "hit go" and hope for the best anymore. They've already seen the part finished in the digital world.

🔗 Read more: NASA Pictures of the Moon: What You’re Actually Looking At

Speed, But Not Just How You Think

Yes, the machine cuts faster. But the real speed benefit is in the setup.

In the old days, setting up a job took hours, maybe days. You had to manually clock in your parts and set your offsets. CAM allows for "offline programming." While the machine is busy cutting Job A, the programmer is in an office (or at a kitchen table) finishing the code for Job B. The moment Job A is done, you load the new program, swap the tools, and keep moving. This "high spindle utilization" is how modern contract manufacturers stay in business while competing with low-wage regions.

It’s also about tool life. CAM doesn't just move the tool; it optimizes how the tool enters the metal. Techniques like trochoidal milling keep a constant load on the cutter. This means the tool stays cool, doesn't chip, and lasts five times longer than it would with "old school" straight-line cuts.

Addressing the Labor Shortage

Let’s be real: there aren't enough master machinists to go around. The "Great Crew Change" is real, and the veterans are retiring. CAM lowers the barrier to entry. While you still need someone who understands "feeds and speeds" and how metal behaves, you don't need every operator to be a math genius. The software handles the trigonometry. This allows a smaller team of experts to oversee a larger fleet of machines, which is basically the only way the industry is surviving the current talent crunch.

The Limitations Nobody Admits

It’s not all magic. CAM software is expensive—sometimes tens of thousands of dollars a year in licensing. And the "Garbage In, Garbage Out" rule applies. If your 3D model is messy, your toolpaths will be messy. You also run into the "black box" problem where operators just trust the code without understanding why the machine is doing what it's doing. If the power goes out or the software glitches, you’re stuck.

Moving Forward: Actionable Steps for Adoption

If you're looking to integrate CAM or upgrade your current flow, don't just buy the most expensive package. Start with your hardware.

- Audit your machines: There is no point in buying high-end 5-axis CAM software if you only run 3-axis Bridgeports. Match the software to the iron.

- Focus on Post-Processors: This is where most people fail. A "post" is the specific translator for your specific machine. If your post-processor is buggy, your CAM is useless. Demand a proven post from your vendor.

- Invest in Training: Software updates every year. A programmer who hasn't had a training class since 2018 is likely missing out on 30% of the efficiency gains modern algorithms offer.

- Try Cloud-Based Options: For smaller shops, platforms like Fusion 360 or Onshape offer lower entry costs and better collaboration than the old-school heavyweights.

Computer-aided manufacturing isn't a luxury anymore. It’s the baseline. If you aren't using it to its full potential, you aren't just slower—you’re eventually going to be obsolete. Start by identifying your biggest "bottleneck" operation and see if a specific CAM strategy, like high-speed machining or automated nesting, can clear it.