You've probably seen the headlines. 3D printing is going to save the world, print a heart by Tuesday, and build a base on Mars by Friday. Honestly, if you follow additive manufacturing research news closely, the reality is way more interesting—and a lot more complicated—than the "magic box" narrative suggests.

We’re sitting in early 2026, and the vibe has shifted. The hype of the 2010s is dead. What's left is a gritty, high-stakes race to make parts that actually stay together under pressure.

The Strongest Aluminum Ever?

MIT researchers just dropped a bomb on the metallurgical world. On December 29, 2025, they published a study showing a new 3D-printable aluminum alloy that is five times stronger than standard cast aluminum. This isn't just a marginal gain. It’s a leap.

They didn't find it by accident. They used machine learning to sift through millions of chemical combinations in a fraction of the time a human lab tech could. This stuff holds its shape at extreme temperatures, which is basically the holy grail for jet engines.

✨ Don't miss: How to Enter Safe Mode Mac Without Losing Your Mind (or Your Files)

The "Dual-Light" Breakthrough at UT Austin

One of the biggest headaches in additive manufacturing is making things that are both hard and soft. Usually, if you want a rigid part and a flexible part, you have to print them separately and glue them. That’s a weak point.

Keldy Mason and the team at The University of Texas at Austin figured out a way to fix this using light. Their research, published in Nature Materials in mid-2025, uses a specialized resin that reacts differently to different colors of light.

- Violet light turns the resin into a stretchy, rubber-like material.

- Ultraviolet light makes it rigid and tough.

Basically, they printed a functional knee joint—bones and ligaments—in one single go. No glue. No assembly. It just works. This is massive for prosthetics. You’ve got a device that can move like a human joint because the transition between "hard" and "soft" happens at the molecular level.

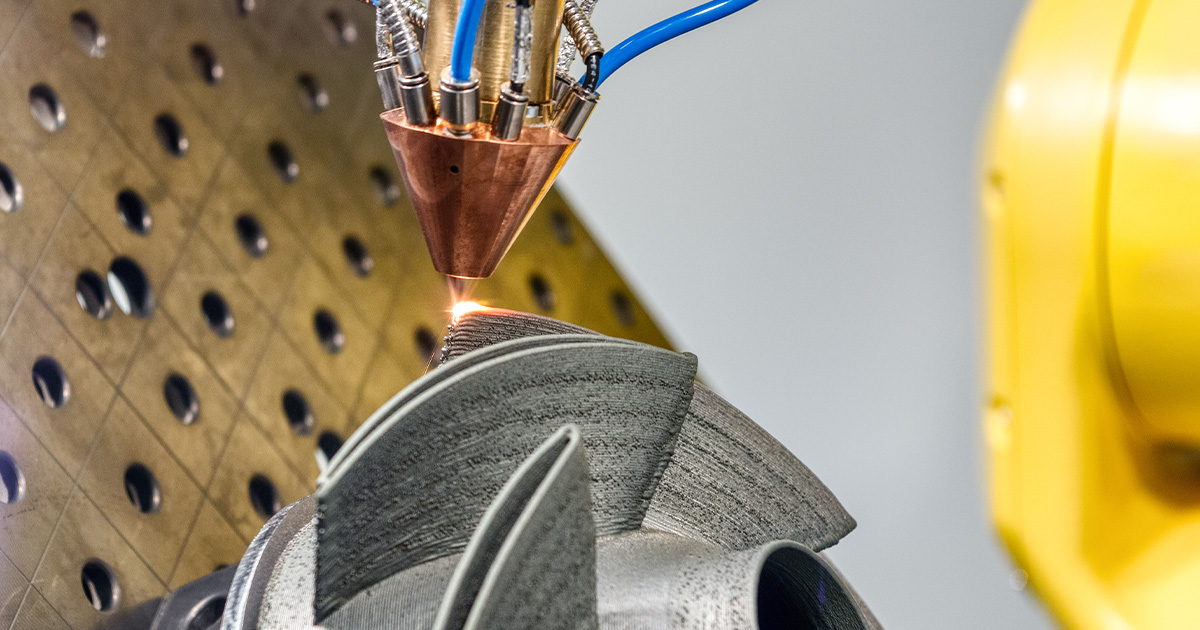

Why 2026 Is the Year of "Born-Qualified" Parts

For a long time, the problem with metal 3D printing was trust. You’d print a part, and then you’d have to X-ray it, stress-test it, and pray there wasn't a tiny air bubble inside that would make a plane engine explode.

👉 See also: How Do I Make My TV Smart? The Easiest Fixes for Your "Dumb" Screen

That’s changing.

The latest research is obsessed with in-situ monitoring. Companies like Oqton and Dyndrite are working with researchers to control the laser at the vector level. We're talking about AI-driven sensors that watch the melt pool in real-time. If the laser fluctuates by a fraction of a millimeter, the system corrects it on the fly.

The goal? Parts that are "born-qualified." This means by the time the printer finishes the job, the data log serves as the certification. No more weeks of post-print testing.

The Pentagon's $3 Billion Bet

If you want to know where the money is, look at the U.S. Department of Defense. Their 2026 budget allocated over $3 billion to additive manufacturing projects. That’s an 83% increase from 2025.

Why the sudden cash injection?

- Distributed Manufacturing: They want to print spare parts for tanks and drones in the field, not wait for a shipment from halfway across the world.

- Hypersonics: You can’t make hypersonic missile components with traditional casting. The geometries are too weird.

- Metal AM Farms: We’re seeing the rise of "farms"—clusters of hundreds of small metal printers working in sync.

Quasicrystals and the Strength Paradox

Here’s something most people missed: researchers found quasicrystals in 3D-printed aluminum alloys. These are rare atomic patterns that shouldn't technically exist in stable form under normal conditions.

🔗 Read more: Why a Fire Engine Spraying Water Isn't as Simple as You Think

But the rapid cooling of the laser in a 3D printer "freezes" these patterns in place. The result? A metal that is incredibly hard but doesn't crack as easily as traditional alloys. It’s a weird quirk of physics that researchers are only now starting to exploit for aerospace armor.

Bioprinting: Not Just for Organs

Everyone talks about 3D printing hearts, but the real additive manufacturing research news in 2026 is about the small stuff.

Micro-tissues.

Labs are now 3D printing "liver-on-a-chip" models to test how cancer drugs react to a specific patient's cells. It’s personalized medicine, but faster. Instead of testing a drug on a mouse and hoping it works for you, they test it on a 3D-printed version of your tissue.

What’s Next? Actionable Steps for 2026

If you're an engineer or a business leader looking at this landscape, the "wait and see" period is over.

- Move Beyond Prototyping: If you're only using 3D printing for models, you're falling behind. The focus now is on serial production of batches in the thousands.

- Audit Your Materials: Standard plastics and metals are becoming commodities. Look into high-performance polymers like PEEK or the new aluminum-matrix composites if you want a competitive edge.

- Software is the Glue: The hardware has peaked for now. The real gains are in the software stacks—AI-based quality control and toolpath optimization.

- Invest in Hybrid: The most successful shops in 2026 aren't "additive only." They are hybrid. They use 3D printing for the complex internal shapes and CNC machining for the surface finish.

The "science project" phase of 3D printing is officially over. We’re in the industrial era now.