You’ve probably seen them without realizing it.

Open up a high-end guitar tuner. Look inside a massive industrial conveyor belt. Peek at the mechanism tilting a solar panel toward the sun. What you’re looking at is a worm and wheel gear set, and honestly, it’s one of the most clever—and misunderstood—inventions in mechanical engineering history.

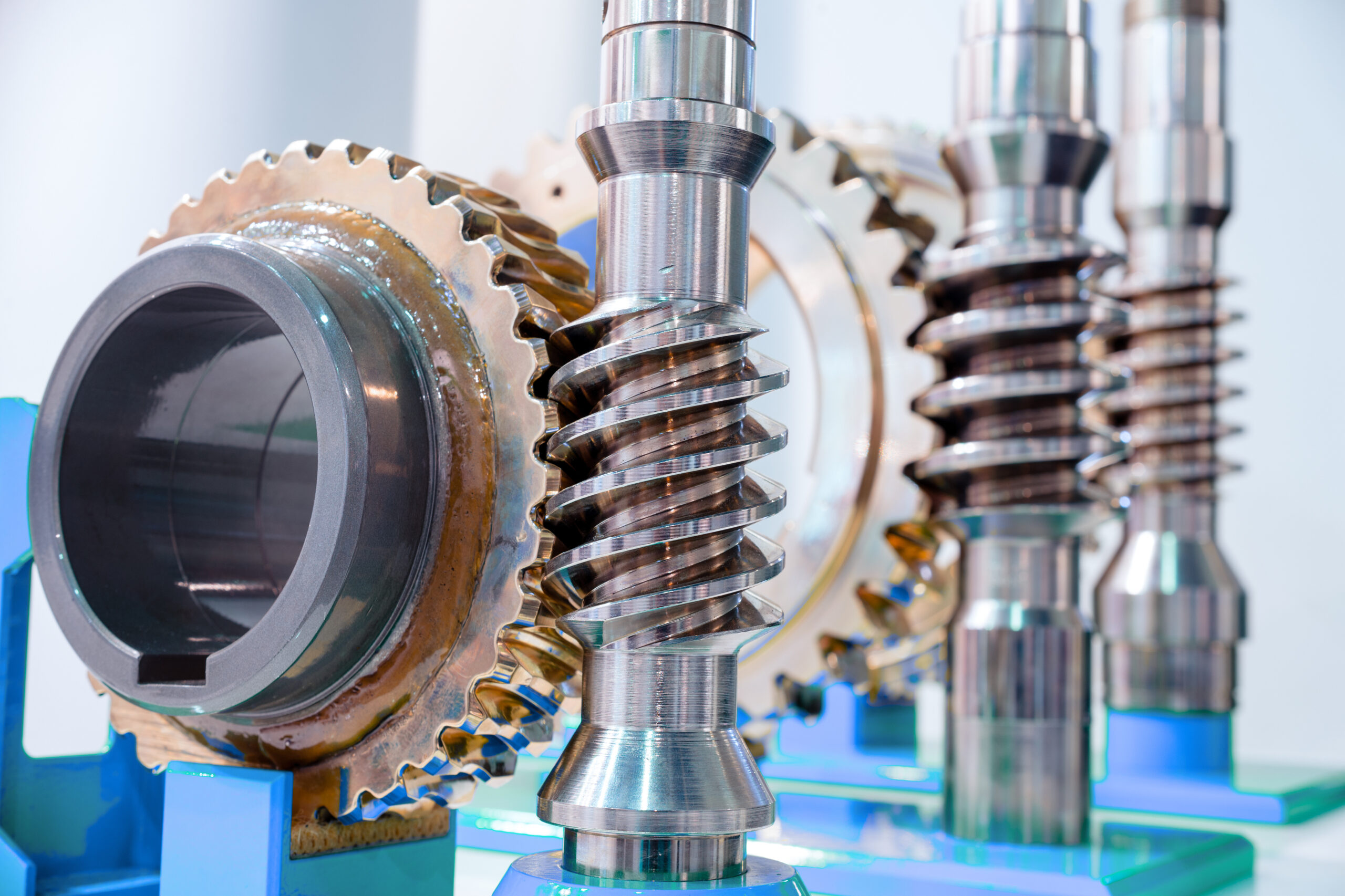

It's basically a screw (the worm) that meshes with a standard-looking gear (the wheel). But that simple interaction creates a mechanical advantage that's almost terrifyingly efficient.

How the worm and wheel gear actually works when things get heavy

Most gears are like a conversation between equals. Two spur gears meet, and they trade speed for torque or vice-versa in a fairly linear way. The worm and wheel gear is different. It’s a power move.

The worm is the driver. It looks like a threaded bolt. When you spin it, those threads slide—literally slide—against the teeth of the wheel. Because the "thread" of the worm is continuous, one full 360-degree rotation of the worm might only move the wheel by a single tooth. Imagine that. If your wheel has 60 teeth, you have a 60:1 gear reduction in a space no bigger than a lunchbox.

But there’s a catch.

Because the movement is based on sliding rather than rolling, friction is the elephant in the room. This isn't like a bicycle chain where things just click along. It’s metal rubbing on metal. This is why you’ll almost always see these gears submerged in heavy-duty oil or coated in thick, specialized grease. Without it, the heat generated would weld the two parts together in minutes.

💡 You might also like: Heavy Aircraft Integrated Avionics: Why the Cockpit is Becoming a Giant Smartphone

The "magic" of self-locking

Here is the thing that makes the worm and wheel gear a literal lifesaver: self-locking.

Think about a standard pulley. If you're lifting a heavy engine and you let go of the rope, that engine is coming down. Fast. But with a properly designed worm gear, the wheel cannot turn the worm. The friction between the threads is so high that the load is essentially frozen in place the moment the motor stops.

This is why they are the gold standard for elevators and lift systems. If the power cuts out, the gear ratio and friction angle prevent the elevator from plummeting. It stays put because the physics of the screw thread won't allow the wheel to back-drive the worm.

Note: This only works if the lead angle of the worm is low enough (usually under 5 to 10 degrees). If you get too aggressive with the pitch, you lose this safety feature.

Material science: Why you see bronze everywhere

If you look at a high-quality worm gear set, you'll notice something weird. The worm is usually shiny, hardened steel. The wheel, however, is often a dull gold color. That’s phosphor bronze.

Why not use steel for both?

📖 Related: Astronauts Stuck in Space: What Really Happens When the Return Flight Gets Cancelled

Because steel on steel is a recipe for a "seizure" when sliding friction is involved. Engineers use "sacrificial" materials. The bronze wheel is softer. It's designed to wear down slowly over decades, conforming to the shape of the steel worm. This "bedding in" process actually makes the gear more efficient over time.

It’s also about heat. Bronze dissipates heat differently than steel, and in a system where 30% to 50% of your energy might be lost to friction-induced heat, you need every thermal advantage you can get.

Real-world applications that might surprise you

- Tuning a Gibson Les Paul: Those little pegs at the top of a guitar? Worm gears. They allow you to make microscopic adjustments to string tension that won't slip back under the massive pull of a steel string.

- Heavy Construction: Think about the massive winches on a tow truck or a crane. They need that 100:1 torque multiplication to pull a semi-truck out of a ditch.

- Conveyor Systems: In bottling plants, you need things to start and stop instantly without coasting. The inherent friction of the worm gear provides that "braking" action naturally.

- Rotary Tables: In high-precision machining (CNC), if you need to rotate a part exactly 0.001 degrees, a worm gear is your only real friend.

What most people get wrong about efficiency

A lot of "internet experts" will tell you that worm gears are "bad" because they are inefficient.

Sorta true, but mostly misleading.

Yes, a spur gear might be 98% efficient, while a high-ratio worm gear might struggle to hit 70%. But that’s a narrow way to look at it. If you tried to get a 60:1 reduction using spur gears, you’d need a massive, multi-stage gearbox that would be heavy, expensive, and loud. The worm and wheel gear does it in one step.

You’re trading energy efficiency for space efficiency and simplicity. In many industrial settings, that’s a trade-off engineers are happy to make every single day.

👉 See also: EU DMA Enforcement News Today: Why the "Consent or Pay" Wars Are Just Getting Started

Dealing with the "Heat Problem"

If you are designing a system with these gears, you have to account for the BTU output. It’s basically a small space heater.

I’ve seen gearboxes fail because someone swapped out the specialized "Steam Cylinder Oil" or high-pressure synthetic gear oil for standard motor oil. Don't do that. You need additives like sulfur-phosphorus compounds that create a microscopic "slick" layer that stays put even when the pressure between the gear teeth is high enough to crush a penny.

Maintenance Checklist for Longevity

- Check the backlash: Over time, as the bronze wheel wears, the gap between the teeth grows. If you're using this for precision (like a telescope mount), you'll need to adjust the center distance.

- Monitor the temperature: if the casing is too hot to touch (usually over 140°F-160°F), your lubrication is failing or your load is too high.

- Metal shavings: A few tiny bronze flakes in the oil are normal during the first 100 hours of "break-in." After that, if you see "glitter" in your oil, the gear is eating itself.

The Future: It's not going anywhere

Even with the rise of high-torque direct-drive electric motors, the worm and wheel gear remains relevant. Why? Because magnets fail. Software glitches. But the geometry of a screw thread is a law of the universe. As long as we need to move heavy things safely and hold them in place without consuming power, we’ll be using these strange, sliding, bronze-and-steel contraptions.

If you're looking to implement one, start by calculating your required output torque and then look at the "Service Factor." Always over-spec by at least 20%. It’s better to have a gear that runs cool and bored than one that’s screaming at its limit.

Your next steps:

Evaluate your specific torque requirements using a standard torque calculator. If your ratio is higher than 20:1 and space is tight, start sourcing a hardened steel worm and a chilled-cast bronze wheel set. Ensure your housing design includes enough surface area for heat dissipation, and never skimp on the synthetic ISO 320 or 460 grade gear oil.