You know that feeling. You finally lugged the 60-pound beast into the window frame, tightened the sash, and realized there is a massive, gaping hole on either side of the machine. It’s frustrating. Most people just pull those flimsy, accordion-style window ac unit side panels until they snap into place and call it a day. But honestly? Those stock plastic "wings" are basically tissue paper for your house. They let in heat, bugs, and—if you live in a noisy city—every single car horn on the block.

Most of us treat these panels as an afterthought. We shouldn't.

The Great Insulation Myth

Most manufacturers include those sliding plastic louvers because they are cheap and adjustable. They fit a 24-inch window or a 36-inch window with the same part. Convenient? Sure. Efficient? Not even close. If you hold a flashlight up to those standard window ac unit side panels at night, you’ll see light bleeding through the seams. If light gets through, air gets through.

Think about it this way. You wouldn't leave a window cracked open two inches while running the heater in the winter. Yet, that’s exactly what a standard side panel does. It has an R-value—a measure of thermal resistance—of basically zero. You are essentially paying the electric company to cool the sidewalk.

Why Your Stock Panels Are Failing You

Standard panels are made of thin PVC. They degrade. The sun’s UV rays bake the plastic until it becomes brittle and yellow. Then, a strong gust of wind or a particularly heavy rainstorm comes along, and suddenly you have a crack. Or worse, the "accordion" folds start to sag, creating a direct highway for mosquitoes and ants.

🔗 Read more: Weather East Highland Park: What to Actually Expect When the Virginia Humidity Hits

I’ve seen people try to fix this with duct tape. Please, don’t be the duct tape person. It looks terrible, and after one week of high humidity, the adhesive turns into a gooey, sticky mess that ruins your window frame finish.

Real experts—the HVAC techs who actually care about home efficiency—usually recommend ditching the stock panels entirely. Brands like Frigidaire or GE make great compressors, but their side-panel game is weak. They prioritize "out of the box" ease over long-term performance. If you want to actually keep the room cold, you need to think beyond the plastic.

Better Alternatives: Foam, Plexiglass, and Wood

If you’re tired of hearing the neighbor’s leaf blower as if it’s inside your bedroom, you need mass.

Insulating Foam Boards: You can buy 1-inch thick rigid foam insulation at any hardware store. Cut it to fit the gap. It's ugly, but it works. You can find "side panel kits" that are basically just high-density foam with an adhesive backing. They block heat way better than the plastic wings.

Plexiglass (The Pro Move): This is the gold standard for aesthetics. You measure the opening, go to a local glass shop or a big-box store, and have a piece of 1/4-inch acrylic cut to size. It looks like part of the window. It lets in light. It doesn't rattle when the compressor kicks on. You seal the edges with a bit of foam weatherstripping, and you’re golden.

Plywood or MDF: If you don't care about the view, a piece of painted plywood is incredibly sturdy. It’s a great theft deterrent, too. A burglar can easily kick in a plastic accordion panel. They aren't kicking through 3/4-inch oak.

The Air Leak Nobody Talks About

It’s not just the sides. When you install window ac unit side panels, you create a secondary problem at the top of the window. Where the lower sash meets the upper pane of glass, there is a horizontal gap. Most people forget to seal this.

You need to stuff that gap with a foam "seal header." If you don't, the hot air from outside just loops over the top of the window and right back into your room. It creates a vacuum effect. Your AC works twice as hard, the motor wears out faster, and your bill goes up $40 a month. It’s a literal cycle of wasted energy.

Stability and Safety Concerns

Let’s talk about the "drop."

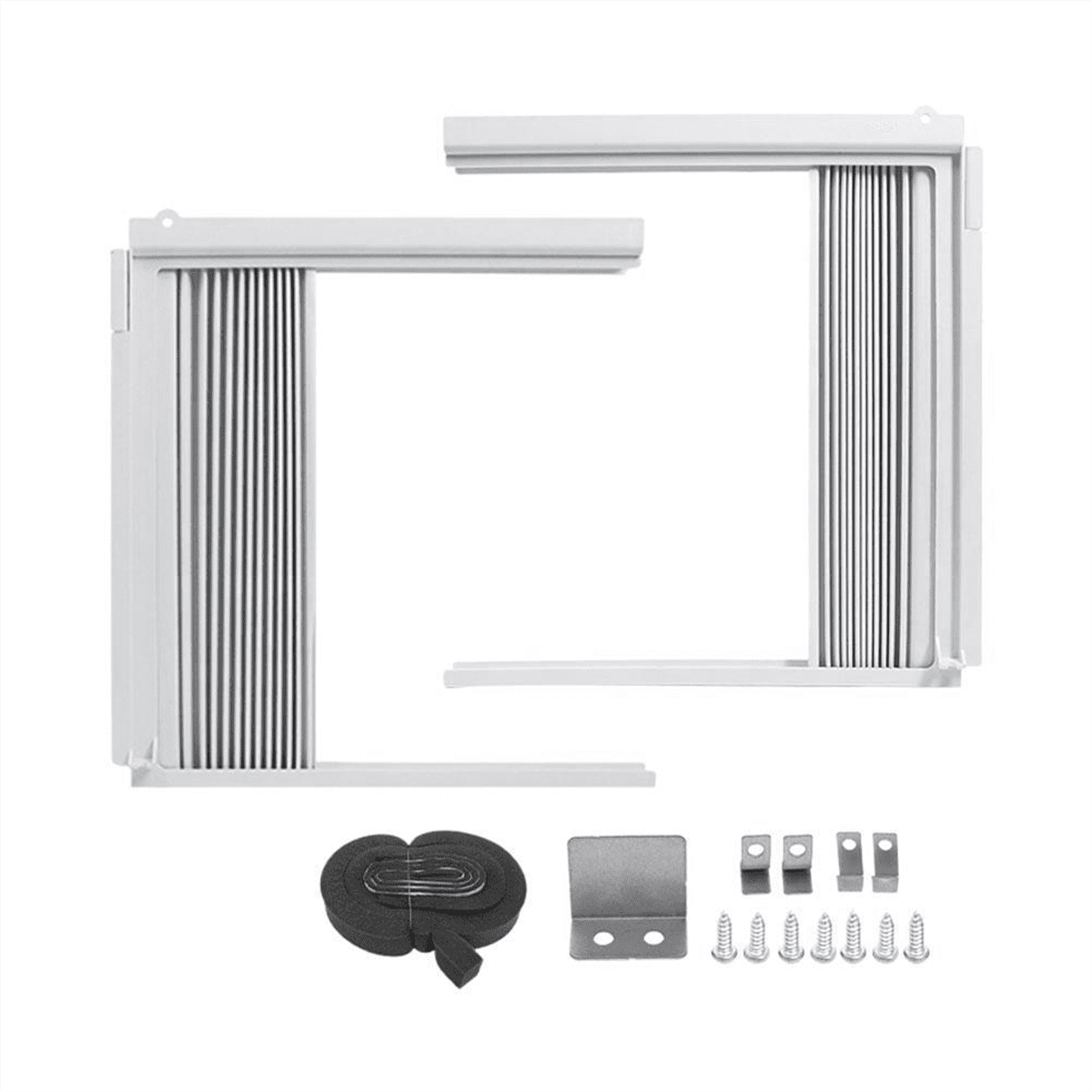

If your side panels aren't secure, the unit itself is less stable. I've seen units tilt backward too far because the side panels weren't providing any lateral tension. While the window sash does the heavy lifting, those panels help center the unit. If you use a DIY foam replacement, make sure you still use the metal "L" brackets that come with the unit to screw the sash into the frame. Do not rely on the panels to hold the AC in place.

Also, consider the rain. Standard panels are angled to shed water, but they often have a "lip" where water can pool against the window sill. This is how you get wood rot. If you are building custom panels, ensure they have a slight outward slope or are sealed with silicone at the base.

What to Do Right Now

If you are staring at your AC unit right now and seeing daylight through the sides, stop. Go to the store.

Get a roll of "Air Conditioner Weatherseal." It’s basically a big block of grey foam. Shove it into the accordion folds of your existing window ac unit side panels. It’s the easiest "hack" to add some R-value without tearing the whole thing apart.

Then, check the "meeting rail"—that gap between the glass panes I mentioned earlier. Stuff it.

If you want a permanent fix, measure your side openings and order a "Side Panel Insulation Kit." These usually come with large foam sheets that you cut with a utility knife. They stick directly to the existing plastic wings. It’s a ten-minute job that can drop the temperature near the window by five degrees instantly.

Stop letting the cold air escape. Your compressor—and your wallet—will thank you.

Actionable Next Steps

- Inspect for Light: Turn off the lights in your room during the day. If you see sunlight through the edges of your AC unit, you have an air leak.

- The Hand Test: Feel around the side panels while the AC is running. If you feel warm air blowing in, your seal is broken.

- Buy Foam: Purchase high-density foam panels to overlay your existing plastic wings for immediate noise reduction and insulation.

- Seal the Top: Ensure the horizontal gap between your window sashes is plugged with a foam gasket.

- Check for Tilt: Ensure your unit still has a slight downward tilt toward the outside (about 1/4 inch) so condensate doesn't leak into your wall, regardless of which panels you use.