You know the sound. You take a sharp left turn and clunk. Somewhere in that massive aluminum box bolted to your truck bed, a heavy pipe wrench just slid across the floor and slammed into your plastic level. It's annoying. Actually, it's worse than annoying—it's expensive. Digging through a chaotic mess of greasy sockets, loose screws, and tangled tie-downs while you’re losing daylight on a job site is a special kind of hell. Most guys just accept the "junk drawer" fate of their truck bed, but honestly, a decent truck tool box organizer tray changes the entire experience of owning a pickup.

It’s just a piece of plastic or metal, right? Wrong.

I’ve spent years around job sites and trailheads, and the difference between a pro and a weekend warrior is usually how fast they can find a 10mm socket. If you’re rummaging, you’re losing. Most high-end boxes from brands like Weather Guard or Dee Zee come with a single, sliding tray, but those are rarely enough. You end up with a layer of heavy stuff on the bottom and a tray full of "everything else" that eventually becomes its own disaster zone.

The Engineering of a Better Truck Tool Box Organizer Tray

Stop thinking of your tool box as a trunk. Think of it as a vertical filing system. When you look at the design of a standard truck tool box organizer tray, it’s meant to bridge the gap between the deep storage of the main tub and the immediate access you need for small items. The physics of a truck bed are brutal. You’re dealing with vibration, moisture, and extreme temperature swings.

Cheap trays crack. I’ve seen those thin poly-molded versions shatter after a single winter in Minnesota because the plastic gets brittle and a heavy hammer bounces the wrong way. A high-quality tray needs to be either heavy-duty HDPE or powder-coated steel. The tray should slide smoothly on the interior lips of the box. If it’s stuck or rattling, it’s failing.

Some people prefer the "tote" style. These are trays with handles that you can actually lift out and carry to the work area. If you’re a plumber or an electrician, this is a game-changer. Instead of walking back to the truck six times, you grab the tray containing your specialized hand tools and take the whole kit with you.

Why Material Choice Actually Matters

Weight is the enemy of efficiency, but flimsiness is the enemy of durability. Aluminum trays are great because they don't rust, which is crucial if you live near the coast or in the salt belt. However, they can be noisy. Every time you drop a screwdriver into an aluminum tray, it rings.

✨ Don't miss: Bed and Breakfast Wedding Venues: Why Smaller Might Actually Be Better

Plastic—specifically high-density polyethylene—is quieter. It dampens the vibration. But here is what most people get wrong: they don't check the load rating. A tray loaded with brass fittings and heavy-duty pliers can easily weigh 20 pounds. If the mounting lip on your tray is only an eighth of an inch thick, it’s going to sag and eventually drop into the abyss of the main box.

Customization vs. Off-the-Shelf Solutions

There is a growing subculture of truck owners who refuse to use the stock trays. They’re building custom dividers using Kaizen foam or 3D-printed inserts. It’s a bit obsessive, but honestly, seeing a truck tool box organizer tray where every wrench has a dedicated, shadow-boarded slot is beautiful.

If you aren't that intense, you can still optimize.

- Use magnetic strips. Glue a magnetic bar to the bottom of the tray to keep drill bits from migrating.

- Check the clearance. Some trays sit too high, preventing the lid of the box from latching properly if you have a taller tool inside.

- Consider the "double stack." Some deep chest-style boxes can actually accommodate two layers of trays if you're handy with a drill and some angle aluminum.

I talked to a guy last week who used a divider system meant for tackle boxes inside his truck tray. It worked perfectly for electrical connectors and wire nuts. He didn't spend $100 on a "professional" system; he just looked at the dimensions and got creative. That's the secret. There is no "perfect" tray out of the box because everyone’s "essential" kit is different.

Dealing With the Moisture Problem

We need to talk about rust. Truck boxes are supposed to be weather-sealed, but condensation is a real thing. If you have a metal truck tool box organizer tray, it can trap moisture against your tools. I’ve seen guys pull out a $150 set of pliers only to find them covered in surface rust because the tray didn't have any drainage or airflow.

A good tray should have small weep holes or at least a textured bottom that allows air to circulate. If yours doesn't, grab a drill and a 1/8-inch bit. It takes two minutes and saves you hundreds in tool replacement. Also, throw a silica gel pack or a vapor corrosion inhibitor (VCI) puck in there. It sounds like overkill until you see what a humid July does to carbon steel.

🔗 Read more: Virgo Love Horoscope for Today and Tomorrow: Why You Need to Stop Fixing People

The Hidden Cost of a Messy Box

Time is money. If you spend five minutes a day looking for tools, that’s about 20 hours a year. At a modest shop rate of $75 an hour, your disorganized box is costing you $1,500 annually. Suddenly, spending $50 on a better truck tool box organizer tray seems like the smartest investment you can make.

It’s also about safety. Reaching into a dark box full of loose, sharp tools is a great way to end up with a tetanus shot. A tray keeps the "stabby" stuff—utility knives, chisels, saws—up top where you can see them.

What to Look for When Buying

Don't just buy the first one you see on Amazon. Measure your box's interior width and the depth of the mounting rails. Many "universal" trays are anything but.

- Reinforced Corners: This is where they always break. Look for thick ribbing on the underside.

- Grip Texture: You don't want your tools sliding to one side every time you hit the brakes.

- Removable Dividers: Flexibility is key. Your tool kit will change over the years; your tray should be able to adapt.

Brands like UWS and Weather Guard have dominated the market because their trays are built for actual work, not just "lifestyle" trucking. They use heavy-gauge materials that can handle the abuse of a vibrating diesel engine and rough dirt roads.

Real-World Use Cases: Beyond the Construction Site

It isn't just for contractors. I know a guy who uses his truck for overlanding and camping. His truck tool box organizer tray is essentially a mobile kitchen. One tray holds the spices, the lighters, and the silverware. Underneath, he keeps the heavy stoves and propane tanks.

For hunters, the tray is where the sharpening stones, extra rounds, and headlamps live. It’s the "immediate access" layer. If you’re out in the woods and you need a light, you don't want to be digging past a floor jack and a tow strap to find it.

💡 You might also like: Lo que nadie te dice sobre la moda verano 2025 mujer y por qué tu armario va a cambiar por completo

The DIY Route: Can You Build a Better One?

Some people hate plastic. I get it. If you have a welder or even just some basic woodworking tools, you can build a custom tray. Plywood is okay, but it absorbs oil and grease. If you go the DIY route, use expanded metal or aluminum sheet.

The advantage of DIY is depth. Most commercial trays are only 3 or 4 inches deep. If you have specific gear—maybe a certain power tool battery charger or a specialized testing meter—you can build the tray to the exact depth required to keep that item snug.

Maintenance and Cleaning

Your tray is going to get gross. Sawdust, metal shavings, and leaked oil will congregate there. About once a month, pull the tray out and dump it. If it’s plastic, hit it with some Dawn dish soap and a hose. If it’s metal, wipe it down with a light coat of WD-40 to prevent any oxidation.

A clean tray also lets you take a quick inventory. If there's an empty spot where your favorite screwdriver usually sits, you'll notice it immediately before you leave the job site. That alone pays for the tray in a month.

Final Steps for a Better Setup

If you’re tired of the clutter, stop looking at the bottom of the box and start looking at the top. The "dead space" in the upper third of your tool box is prime real estate.

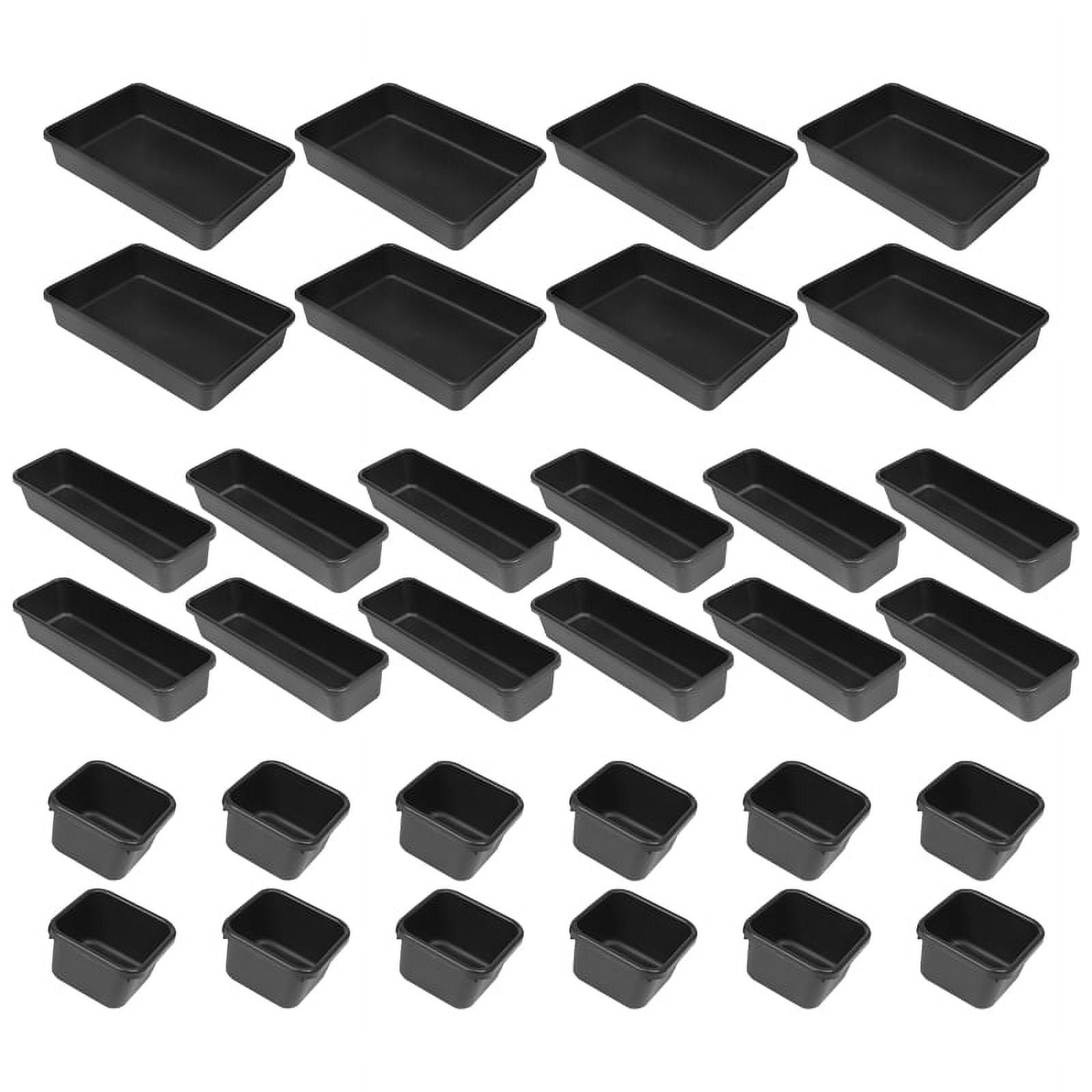

Start by measuring the inside lip of your current box. Don't trust the manufacturer's website; get a tape measure and do it yourself. Look for a truck tool box organizer tray that offers at least three compartments. Use the smallest compartment for "consumables" like electrical tape, zip ties, and earplugs. Use the long compartment for your primary hand tools.

Once you get the tray, don't just throw everything back in. Purge. If you haven't used that rusted-out wrench in three years, it doesn't belong in the tray. It belongs in the bottom or in the trash.

The goal is to reach into your box and find what you need without looking. That’s the "pro" level of organization. It’s a small change that makes a huge impact on how you use your truck every single day. Stop the clunking and start organizing.