You bought a Speed Queen because you were tired of the "planned obsolescence" cycle. You wanted the tank. You wanted the machine that lasts twenty-five years while the flashy, touchscreen competitors end up in a landfill after six. Then, one Tuesday afternoon, you pull out a load of towels and they’re damp. Ice cold. The betrayal feels personal. When a speed queen dryer heating element stops glowing, it’s rarely because the machine is "junk." Usually, it’s a specific, solvable physics problem that happened because of how the machine is vented or how the internal airflow is restricted.

Speed Queen builds their dryers with heavy-duty components, but even the best nickel-chromium alloy coil has its limits. If the heat can’t leave the drum, the element basically cooks itself. It’s a bit like redlining an engine while the car is in park. Eventually, something gives.

Most people panic and call a tech. You might not need to. Honestly, if you can use a nut driver and have an afternoon, you can likely diagnose and swap this part yourself. But before you go ordering a 510107P element assembly, you need to understand why it happened so you don't just burn out the replacement in three months.

The Brutal Physics of the Speed Queen Dryer Heating Element

The heating element is essentially a giant toaster wire. In a Speed Queen electric dryer, this coil—typically made of a nichrome alloy—is housed in a metal heater box. When 240 volts of electricity hit that coil, resistance turns that energy into heat. The blower motor then pulls air across these scorching coils and pushes it into the drum.

📖 Related: Brandy Melville Stores Like These Are Changing How We Shop Fast Fashion

It's a simple system. But it’s a balanced one.

The most common reason for failure isn't a defect. It's lint. Not the lint in your trap, but the lint in your vent line. When the exhaust is blocked, the air stays trapped around the element. It gets hotter than it was ever designed to be. Most Speed Queens have a thermal fuse or a high-limit thermostat designed to cut power before a fire starts, but if those cycles happen repeatedly, the element wire eventually becomes brittle and snaps.

Sometimes it’s just age. Even a Speed Queen isn't immortal. Over thousands of cycles, the metal expands and contracts. It grows thin. One day, it just breaks the circuit. You'll know it's the element if the dryer spins, the timer ticks, the lights are on, but the air is stone-cold.

Identifying the Part and the Complexity

Depending on your model—whether you have the classic mechanical dial LD3 or the electronic front-control DF7—the element might look slightly different, but the core tech is the same. Speed Queen often uses a 5,350-watt element. That's a lot of juice.

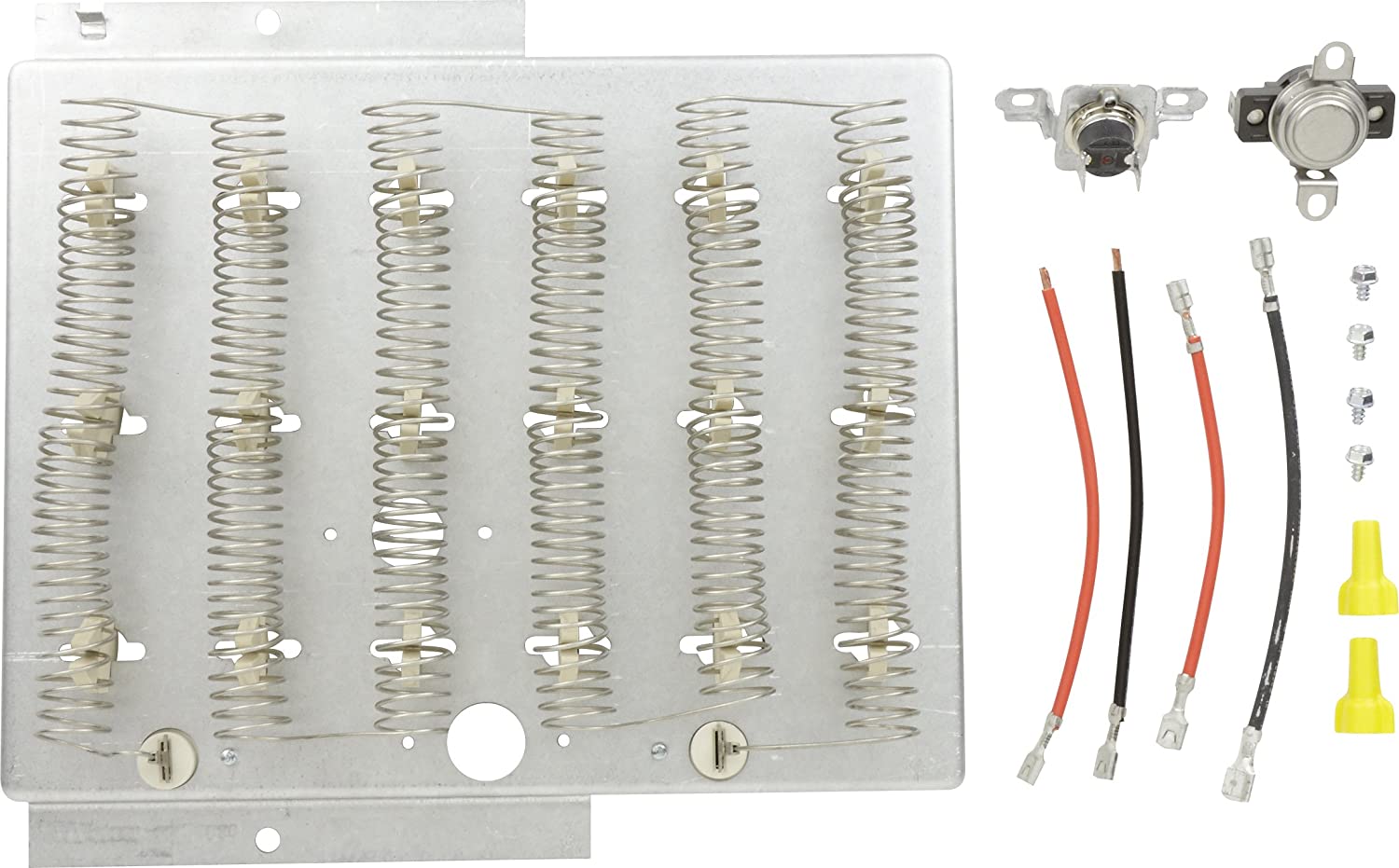

Look at your model number. If it starts with ADE (Alliance Dryer Electric), you’re looking for a specific assembly. Unlike some cheap brands where you just buy a loose coil and "stretch" it into an old housing, Speed Queen parts usually come as a pre-strung assembly. It's more expensive, sure, but it’s way more reliable. It prevents the "hot spots" that happen when a DIYer stretches a coil unevenly.

Is It Definitely the Element?

Wait. Don’t buy the part yet.

I’ve seen dozens of people tear their dryer apart only to realize the heating element was fine. Before you go deep, check your circuit breaker. Electric dryers run on two "legs" of 120V power. If one leg trips, the dryer might still have enough power to turn the drum and light up the panel, but not enough to energize the heating coils. Flip the breaker all the way off and then back on.

Still cold?

Next, check the thermal fuse. On most Speed Queen models, this is a small white plastic component on the blower housing. If this blows, the heater won't turn on. It’s a safety device. You can test it for continuity with a cheap multimeter. If the multimeter doesn't beep, the fuse is dead. Replacing a $15 fuse is a lot easier than replacing a $100 speed queen dryer heating element.

👉 See also: Cooking Aprons for Women: What Most People Get Wrong About Choosing the Right One

The Multimeter Test

If you're serious about this, get a multimeter. Set it to Ohms ($\Omega$). Touch the probes to the two terminals on the heating element. You're looking for a reading between 7 and 12 ohms.

If the screen shows "OL" (Open Loop) or infinite resistance, the wire is broken. It's toast. Literally. If you see a physical break in the coil—a drooping wire or a charred black spot—you don't even need the meter. The visual is enough.

The Tear-Down: Getting to the Heat

One thing people love about Speed Queen is that they are built to be serviced from the front. Most modern "big box" dryers require you to take the whole back off or, worse, remove the entire drum just to see the heater. Not here.

- Unplug the machine. Do not skip this. 240 volts is enough to be fatal.

- Remove the front panel. On many models, there are two screws at the bottom. You pull the bottom out and the top clips release.

- The Heater Box. You’ll see a long metal galvanized box, usually on the right side. That’s where the magic happens.

- Disconnect the wires. Take a photo first. You think you’ll remember where the orange wire goes. You won't.

- Slide it out. There are usually just a few screws holding the element assembly into the heater box.

It’s actually a very satisfying repair. Everything is heavy-duty. The screws are real metal, not the soft zinc that strips the moment you look at them.

Why Authentic Parts Matter Here

You'll see "compatible" heating elements on Amazon for $30. Don't do it.

I know, it's tempting. But those cheap coils often use thinner gauge wire or inferior alloys. They might work for a month, but they often lack the heat-cycling durability of the OEM (Original Equipment Manufacturer) Alliance Laundry Systems parts. A genuine Speed Queen element is designed to handle the specific CFM (cubic feet per minute) of the Speed Queen blower.

Using a knock-off can also lead to "sagging." When a coil sags and touches the metal housing, it shorts out. This can stay "on" even when the dryer is off, which is a massive fire hazard. Stick to the genuine 510107P or whatever specific part number your manual dictates.

The Lint Factor

If you replace the element and don't clean your vents, you're just lighting money on fire.

Go outside. Look at your vent hood. Is it covered in fuzz? Take a vacuum or a leaf blower (yes, it works) and clear that line. If your vent is longer than 20 feet or has multiple 90-degree elbows, your element is working twice as hard as it should. Speed Queen machines have powerful blowers, but they can't beat physics. High backpressure equals high heat, and high heat kills nichrome.

The Cost of Professional vs. DIY

If you call a repair service, you’re looking at a $100–$150 service call fee, plus the marked-up price of the part, plus labor. You’ll easily clear $300.

Doing it yourself? The part is roughly $70 to $110 depending on where you buy it. You save $200 and you gain the smug satisfaction of knowing exactly how your machine works.

Nuance in Different Models

If you have one of the newer front-load Speed Queens (the ones that look like they belong in a laundromat), the access is slightly different. The stack units are a bit more of a nightmare because of the cramped quarters. But the fundamental tech—the coil in the box—hasn't changed much in decades.

Some people ask about "restretching" a broken coil. Some old-school guys used to do this—basically overlapping the broken ends and twisting them together. Do not do this. It creates a point of extreme resistance. It will burn out again, and it’s a genuine fire risk. If the wire is broken, the part is dead.

Actionable Steps for a Cold Dryer

If you are standing in front of a cold Speed Queen right now, follow this sequence. Don't skip around.

- Step 1: Check the Power. Go to your home's breaker box. Reset the 30-amp double breaker for the dryer. Even if it looks "on," flip it off and back on.

- Step 2: Inspect the Duct. Disconnect the silver flex-hose from the back of the dryer. Try running a small load. If the dryer gets hot now, your house ducting is clogged. If it's still cold, the problem is internal.

- Step 3: Test the Thermal Fuse. Open the cabinet. Use a multimeter to check for continuity on the small fuse located on the blower housing. If it's open, replace it.

- Step 4: Inspect the Heating Element. Check for continuity across the element terminals. If the meter shows no continuity, or if you see a physical break in the coil, order a genuine Alliance Laundry Systems replacement part.

- Step 5: Vacuum the Interior. While the cabinet is open, vacuum out all the stray lint that escaped the drum. This prevents future fires and helps the new element breathe.

Most people find that once they replace the element and clear their vents, the dryer actually performs better than it did for the previous two years. You'll notice shorter dry times and less "laundry day stress."

Speed Queens are designed to be the last dryer you ever buy. A failed heating element isn't a sign of a bad machine; it's usually just a sign that the machine was working harder than it was meant to. Treat it right, clear the airflow, and use quality parts. Your machine will likely outlast your next car.