You’ve been there. It’s 2:00 PM on a Tuesday, the heat in the warehouse is rising, and you’re staring at a stick of 3/4-inch EMT that looks more like a pretzel than a 30-degree offset. You used the "standard" multipliers. You marked the lines. Yet, when you try to saddle over that junction box, the pipe is short by two inches and the box is crooked. This is where an electrical conduit bending calculator stops being a luxury and starts being the only thing saving you from a scrap pile tall enough to hide a forklift.

Bending pipe is an art, sure. But it’s mostly math. Specifically, it’s trigonometry that most of us haven’t looked at since high school. If you're relying on the sharpie marks on your bender’s shoe to do the thinking for you, you’re basically guessing. Real precision comes from understanding how the physics of the metal reacts to the pressure of the hickey or the foot-pedal.

👉 See also: Help Me Use GPT-5 Codex for Coding: What Actually Works Right Now

The Math Behind the Metal

Let's get real for a second. Most guys learn the "multiplier" method. You want a 30-degree bend? Multiply the offset depth by 2. Easy. But what happens when you're working with rigid pipe instead of EMT? Or when your bender has a slightly different radius because it’s been dropped off a scissor lift six times?

A digital electrical conduit bending calculator handles the stuff your brain skips. It accounts for the "shrink." When you bend a pipe, it gets shorter. It's a physical law. If you need to clear a 4-inch obstacle with a 30-degree offset, that pipe is going to "shrink" by 1/4 inch for every inch of offset depth. That’s a full inch of pipe gone. If you don't account for that in your first mark, your run is going to be short.

Why Multipliers Fail in the Field

Standard multipliers like 1.41 for 45 degrees or 2.0 for 30 degrees assume a perfect world. They assume your pipe is exactly the diameter it says on the label and that your bender hasn't lost its calibration.

I’ve seen apprentices try to use an electrical conduit bending calculator app without knowing their "Center of Bend." That’s a recipe for disaster. Every bender has a specific point where the bend actually starts in relation to the arrow on the shoe. If you don't find that first, the most expensive software in the world won't help you. You'll keep getting "dog legs"—those nasty twists where your second bend isn't on the same plane as your first. It’s embarrassing. It looks unprofessional. And in high-spec industrial jobs, the foreman will make you rip it out.

Trigonometry vs. The "Good Enough" Method

The secret sauce of any decent calculator is the Sine function. $Offset = Distance \times \sin(Angle)$.

Most people don't want to do $1/ \sin(30)$ in their head while standing on a ladder. That’s why we use the "2" multiplier for 30 degrees. It’s just the reciprocal of the sine. But what if you need a 22.5-degree bend because a 30 is too sharp and a 10 is too shallow? A 22.5-degree bend uses a multiplier of 2.6. If you're off by even a decimal point over a long run, your conduit won't sit flush against the wall.

Handling the Four-Point Saddle

Saddles are the ultimate test. You’re going over a 6-inch pipe. You want to use 45-degree bends in the middle and 22.5-degree bends on the ends to keep the profile low. Try calculating those four marks, accounting for shrink, and keeping the pipe straight manually. You’ll be there all day.

An electrical conduit bending calculator lets you plug in the diameter of the obstruction and the angle you want. It spits out three or four marks. You mark the pipe, line up the arrow, and pull.

🔗 Read more: Sexy pics on snapchat: Why your privacy strategy is probably failing

- Mark A: The start of the first bend.

- Mark B: The peak.

- Mark C: The return.

If you’re doing it right, the pipe should "hug" the obstruction with less than an eighth of an inch of daylight. That’s the difference between a "handyman" job and "master electrician" work.

Common Mistakes That No App Can Fix

Even with the best tech, you can mess up. The biggest issue? Pressure. If you don't keep constant foot pressure on the bender shoe, the pipe will kink. It doesn't matter if your math was perfect down to the millimeter. A kinked pipe is a ruined pipe. It’s also a code violation because it restricts the internal area for wire pulling.

Then there’s the "springback."

Metal has memory. When you release the tension on a 90-degree bend, it might relax back to 88 degrees. Professional calculators often have a "springback" adjustment. You might actually need to pull to 93 degrees to finish at a perfect 90. This varies by brand. Southwire pipe might behave differently than Wheatland Tube depending on the thickness of the galvanization.

The Problem with "Eye-Balling" It

I once watched a guy try to bend a 5-inch offset in 1-inch rigid by "feeling" the angle. He wasted four sticks of pipe. At current copper and steel prices, that's a few hundred bucks down the drain. He could have used a $5 app or a free online electrical conduit bending calculator and finished the job in ten minutes.

Don't be that guy. Use the tool.

Digital Tools vs. Pocket Manuals

There are plenty of options out there. Some guys swear by the Ugly’s Electrical References book. It’s a classic for a reason. It has the tables. It has the charts. But it doesn't move. It doesn't adjust for your specific bender's shoe radius.

Modern apps and web-based calculators allow for "Cosecant" calculations and "Gain" adjustments. Gain is a big one. It’s the difference between the distance around the curve and the distance if the pipe made a sharp 90-degree corner. If you’re trying to land a pipe in a specific knockout on a box, you have to know the gain, or you’ll over-shoot the box every time.

How to Calibrate Your Calculator

Before you trust any electrical conduit bending calculator, you need to calibrate your tool. Here is how you actually do it:

👉 See also: Ethical Hacking: How I Hack Google (The Right Way)

- Take a scrap piece of pipe.

- Make a mark at 10 inches from the end.

- Place the bender's arrow on that mark.

- Bend a perfect 90.

- Measure the distance from the end of the pipe to the back of the 90.

- If that distance is 15 inches, your "stub-up" deduct is 5 inches.

Plug that "5" into your calculator settings. Now, the app knows your specific tool. This is why some guys can bend pipe in the dark—they know their tool's numbers.

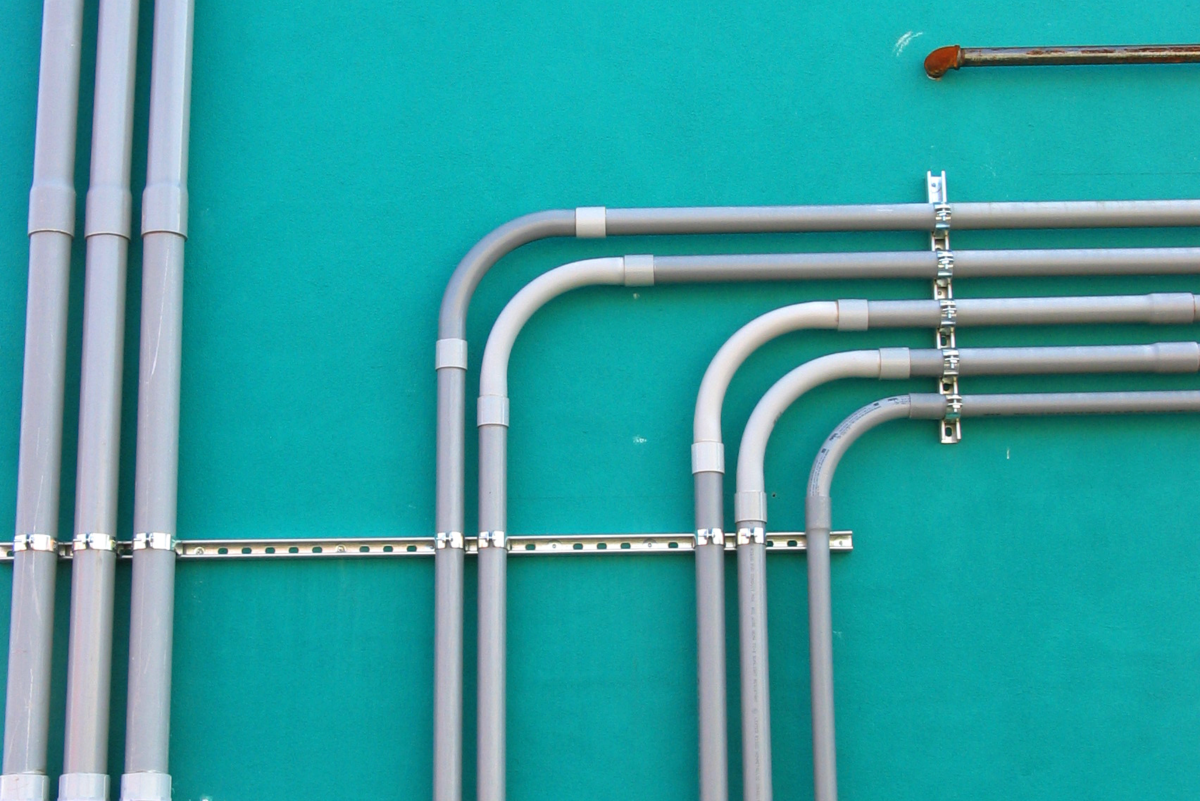

Beyond the Basics: Concentric Bends

If you're working in a high-end data center or a hospital, you'll eventually have to do concentric bends. This is where you have five or six pipes of different sizes turning a corner together. To make them look uniform, the radius of each bend has to increase slightly so the gap between the pipes stays the same.

Doing this manually requires a scientific calculator and a lot of patience. An electrical conduit bending calculator designed for industrial use can generate a "bend schedule." It tells you exactly where to move the mark for each subsequent pipe. It’s the highest level of the craft.

Practical Steps for Your Next Project

If you want to stop wasting material and start looking like a pro, change your workflow.

First, stop guessing your angles. Use 10, 22.5, 30, 45, or 60. These are the standard angles for a reason—the multipliers are predictable.

Second, get a decent electrical conduit bending calculator on your phone. There are free ones like Conduit Runner or paid ones that offer more complex layout features.

Third, verify your "shrink" and "gain" values for the specific brand of pipe you’re using on that job site.

Finally, check for "dog legs" before you make your second bend. Lay the pipe on a flat floor. If the first bend isn't perfectly flat against the concrete while you're preparing the second, you're already in trouble.

Stop fighting the pipe. Use the math, trust the calculator, and keep your foot on the shoe. You’ll find that "impossible" runs suddenly become a lot easier when you aren't fighting the laws of geometry with a hacksaw in your hand.