You’ve seen the photos. Some guy on Reddit or Instagram posts a life-sized, weathered 3D printed Master Chief that looks like it stepped right out of a Blur Studio cinematic. It’s intimidating. Then you look at your own printer—a humble Ender 3 or maybe a shiny new Bambu Lab—and you wonder why your prints look like melted LEGO bricks.

The gap between a "plastic toy" and a "legendary Spartan" is massive.

Honestly, most people fail because they treat a 3D printed Master Chief like a standard trinket. It isn't. Whether you're making a 6-inch desk statue or a wearable suit of MJOLNIR Mark VI armor, you’re dealing with complex geometry that Halo’s original artists at Bungie and 343 Industries never intended for a nozzle to extrude. We’re talking about undersuits, hard-surface plating, and those iconic hexagonal patterns.

The File Problem: Game Assets vs. Print Files

Here is the thing about game files. They are hollow. In the actual Halo Infinite or Halo 3 game engine, Master Chief is basically a "shell" with no thickness, held together by digital prayers and code. If you try to rip a model straight from the game and hit 'print,' your slicer will have a literal stroke.

You need manifold models.

Real experts in the community, like the folks at the 405th Infantry Regiment, spend hundreds of hours "thickening" these meshes. If you're looking for the gold standard, creators like MoeSizzlac or Galactic Armory are the names you'll see popping up. They don't just provide a shape; they provide a blueprint. They account for things like "print orientation."

📖 Related: Can You Play BO6 Split Screen? What Most People Get Wrong

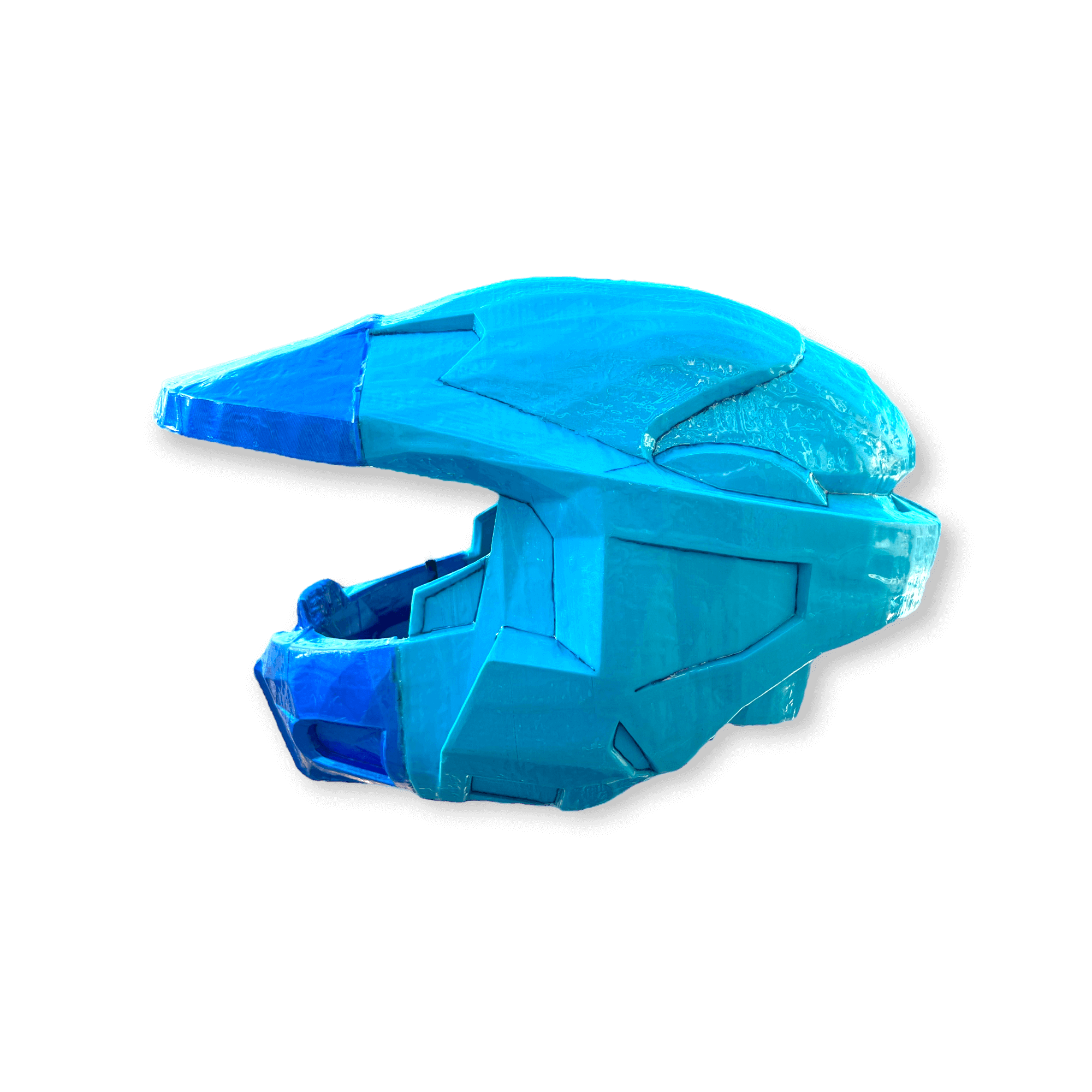

Think about the helmet. If you print a Master Chief helmet vertically, the top of the dome is going to have nasty "top layers" that look like a topographical map of the Andes. You have to tilt it. About 45 degrees backward is usually the sweet spot to keep the visor area clean.

Resin vs. FDM: Choosing Your Weapon

Which printer is actually better for a 3D printed Master Chief? It depends on your patience and how much you value your lungs.

Fused Deposition Modeling (FDM), your standard filament printer, is the king of big builds. If you want a 1:1 scale Chief in the corner of your man cave, you’re using PLA or PETG. It’s cheap. It’s (relatively) sturdy. But the layer lines? They’re a nightmare. You’ll spend weeks sanding. Seriously, your shoulders will ache.

Resin (SLA) is different.

Resin gives you that "is this official merch?" quality. The detail on the tech-suit—those tiny rubberized textures—actually shows up. But resin is brittle. Drop a resin Chief on a hardwood floor and he’s going to shatter faster than a Grunt seeing a Plasma Grenade. Plus, the build plate size on most consumer resin printers is tiny. You’d have to slice a 12-inch Chief into twenty pieces.

Most high-end makers are now doing a hybrid. They print the big armor plates on a Voron or a Bambu and do the "hero" pieces—the helmet, the AI chip slot, the MA40 Assault Rifle—in resin for that crisp detail.

The "Secret Sauce" is Actually Just Bondo

If you want your 3D printed Master Chief to look authentic, the printing is only 30% of the job.

Post-processing is where the magic happens. Or the misery.

You start with a heavy-grit sandpaper. 80 grit. It feels wrong, like you’re ruining it. You’re not. You’re leveling the "stairs" created by the printer layers. After that, it’s all about filler primer. Rust-Oleum Filler Primer is the industry secret. It’s a thick, high-build spray paint that fills in the microscopic valleys.

Spray. Sand. Spray. Sand.

Eventually, you get to the painting. Master Chief isn't "green." Not really. He’s a specific, desaturated olive drab. If you use a bright "Kelly Green" from the hardware store, it’s going to look like a toy. You want something closer to Tamiya Olive Drab or even specialized paints like those from The Armored Garage.

💡 You might also like: Finding Princess Peach Coloring Pages Free Without the Clickbait

And don't forget the weathering. A clean Master Chief is a Master Chief who hasn't been doing his job. You need "silver rubbing." Take a tiny bit of silver acrylic on a dry brush and hit the edges of the armor. It simulates paint being chipped off the metal underneath. Then, slop on a "black wash"—watered-down black oil paint—and wipe it away. It stays in the cracks. It adds depth. It makes the plastic look like heavy, battle-worn titanium.

Why 1:1 Scale Armor is a Different Beast Entirely

Let's talk about the crazy people. The ones who 3D print the full suit.

Doing a full 3D printed Master Chief suit takes about 10 to 15 kilograms of filament. That’s roughly $300 just in raw plastic. But the real cost is time. A single thigh piece can take 40 hours to print. The torso? Maybe 100 hours.

The biggest mistake? Scale.

Everyone thinks they can just measure their height and hit go. They forget about "internal clearance." You have to fit your body plus padding plus the thickness of the plastic. If you don't scale it right, you'll finish the print and realize you can't actually bend your knees. You’ll be walking like a penguin.

Use software like Armorsmith Designer. It lets you create a virtual avatar of your actual body measurements and "drape" the 3D files over it. It saves you from wasting $50 on a helmet that won't fit over your nose.

The Tech-Suit Dilemma

One thing people always miss is the "undersuit." In the games, Chief has this ribbed, black carbon-fiber-looking suit under the plates. You can't 3D print that out of hard plastic—you wouldn't be able to move.

The pros usually go one of two ways:

- The Budget Way: A black quilted motorcycle sub-suit or a textured compression shirt.

- The Pro Way: 3D printing "stamps" or molds, then using those to cast flexible silicone or urethane rubber pieces that are sewn onto a fabric base.

It’s incredibly tedious. But when you see the armor plates sitting on top of real, textured rubber instead of just a flat black spandex suit, the realism jumps 200%.

What People Get Wrong About the Visor

You can’t really 3D print a transparent visor. Not well, anyway. Even "clear" resins come out foggy and yellowed.

Most makers print a "buck"—a solid version of the visor—and then use a vacuum forming machine to pull a sheet of heated PETG plastic over it. Then comes the "Gold Chrome" finish. You can’t just spray paint it gold, or you won't be able to see out of it. You need a specialized coating, often something like "one-way mirror" film or a very expensive chrome pigment like Alclad II, followed by a gold tint.

✨ Don't miss: How to Make Pancakes in Toca Boca: What Most Players Get Wrong

Some guys are now using motorcycle helmet visors and cutting them to shape, but the Chief’s visor has a very specific hexagonal pattern in the modern games. Laser engraving that pattern into the PETG before you form it? That’s the pro move.

Realities of the Hobby

It’s not cheap. A decent 3D printed Master Chief (the 12-inch variety) will cost you about $50 in materials and another $50 in paints and supplies. A full suit? You’re looking at $1,000 minimum by the time you add straps, lights, fans (you will sweat to death in that suit), and padding.

Also, it breaks. 3D prints are layers of plastic stuck together. They are not as strong as molded plastic. If you're wearing a suit to a con, you will snap a piece. You have to carry a "medical kit"—super glue, 5-minute epoxy, and extra green paint.

Actionable Steps for Your First Print

Don't go big immediately. You’ll burn out and your printer will clog, and you'll end up with a half-finished Spartan leg in your closet for three years.

- Start with a "Calibration Cube": Boring, I know. But if your printer isn't dimensionally accurate, your Master Chief's left arm won't fit into the shoulder socket.

- The "Head Test": Print a Master Chief helmet at 10% scale. See how the supports work. Figure out the orientation. It takes two hours instead of two days.

- The 405th Forum: Join it. Don't just lurk. These people have been perfecting Spartan armor since 2004. They have "unfolded" files for every version of Chief from Halo: CE to Infinite.

- Master the Slicer: Learn about "Tree Supports." Standard blocky supports are a nightmare to remove from the complex nooks of a MJOLNIR suit. Tree supports (especially in OrcaSlicer or Cura) pop off like a dream and save a ton of filament.

- Safety First: If you’re sanding PLA or resin, wear a mask. Plastic dust in your lungs is a one-way ticket to a bad time.

Building a 3D printed Master Chief is basically a rite of passage for makers now. It's the ultimate test of your printing, sanding, and painting skills. It’s frustrating. You’ll probably run out of filament at 98% on a three-day print at least once. But when you finally put that helmet on, or set that perfectly weathered statue on your desk, it feels like you've actually brought a piece of the 26th century home.

Just remember: finish your sanding. No matter how much you hate it, sand for another hour. Your Spartan deserves it.

Key Resources for Makers

- The 405th Infantry Regiment: The definitive community for Halo costuming.

- Thingiverse/Printables: Good for free, low-detail "fan" models.

- Etsy: Where you find the high-fidelity, "print-ready" files from professional 3D artists.

- Halo Archive: Great for finding high-resolution reference images so you get the paint chips in the right spots.

Next Steps:

If you're ready to start, download a "torture test" file to see how your printer handles overhangs. This will tell you if you're ready for the complex curves of a Mark VI helmet. Once that's dialed in, pick your favorite version of the Chief—whether it's the bulky Halo 4 look or the classic Halo 3 silhouette—and start with the helmet. It’s the smallest "win" that gives the most satisfaction.