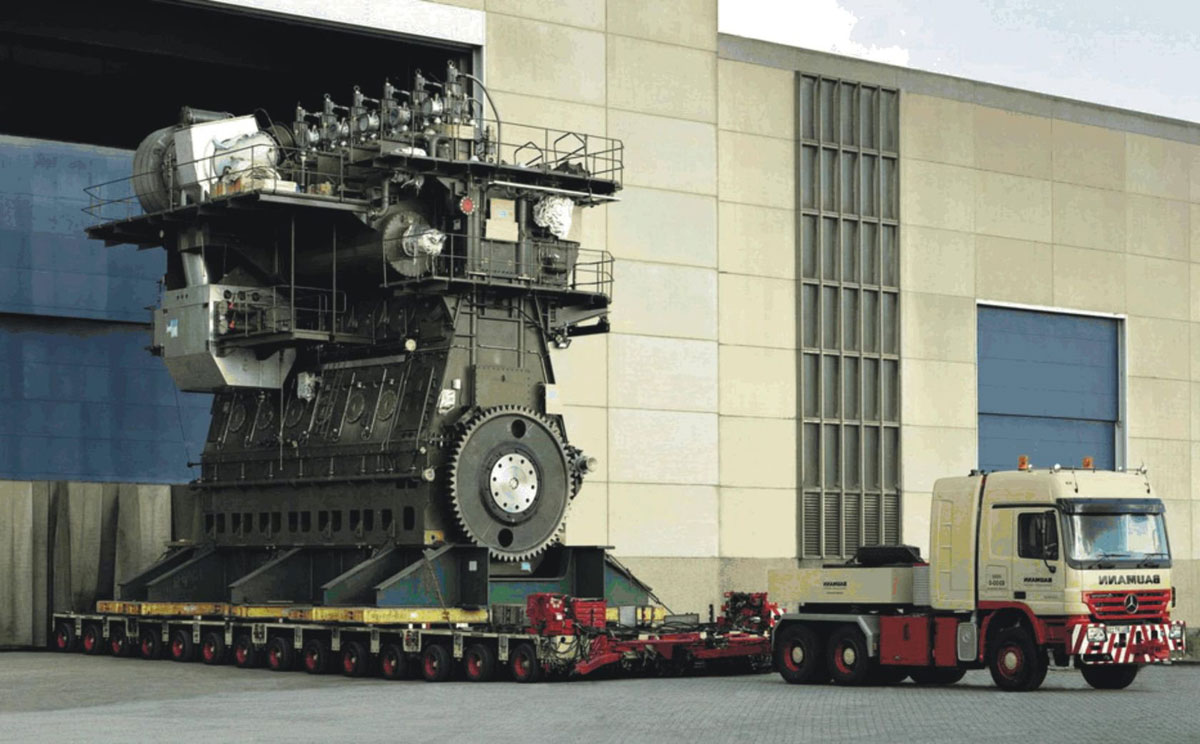

Imagine a machine as tall as a four-story apartment building. Now imagine that machine isn't just sitting there; it's vibrating with the force of 100,000 horses. That is basically the Wärtsilä Sulzer 14RT-flex96C. It's the kind of engineering that makes you feel small. Honestly, most people don't realize that the global economy—your phone, your shoes, the coffee beans in your kitchen—pretty much relies on this specific hunk of metal.

It’s big. Really big.

When you look at the specs, it’s easy to get lost in the numbers. We are talking about a 14-cylinder, two-stroke turbocharged diesel engine. But calling it a "diesel engine" feels like calling the Saturn V a "bottle rocket." It was designed by Wärtsilä and Sulzer (which is now part of the same family) to power the "Emma Maersk" and her sisters, the massive E-class container ships that dominate the horizon at ports like Long Beach or Rotterdam.

The Raw Power of the 14RT-flex96C

Let’s get the "holy crap" stats out of the way. This thing weighs over 2,300 tons. The crankshaft alone is 300 tons. If you stood inside one of the cylinders, you’d have plenty of headroom because the bore is almost a meter wide. The stroke? More than 2.4 meters.

It produces roughly $80,080$ kW of power, which translates to about 107,389 horsepower.

You’ve got to wonder how something that massive stays efficient. Usually, when things get this big, they get clunky. Not here. The 14RT-flex96C uses "common rail" technology. Instead of the old-school mechanical camshafts that timed fuel injection using gears and lobes, this uses electronically controlled high-pressure pumps. This "flex" technology is why the engine doesn't cough out thick black clouds of soot every time it starts up. It’s precise. It injects fuel at exactly the right micro-second to ensure total combustion.

The thermal efficiency is actually incredible. Most car engines are lucky to hit 30% or 35% efficiency. This monster? It crosses the 50% threshold. That means more than half of the energy in the fuel is actually being turned into motion rather than just wasted heat. In the world of shipping, where fuel costs are the difference between a billion-dollar profit and bankruptcy, that efficiency is everything.

👉 See also: Texas Internet Outage: Why Your Connection is Down and When It's Coming Back

Why 14 Cylinders and Not 12?

You might think adding two cylinders is just about more power. It's more complicated. Ships like the Emma Maersk need to maintain a certain speed—usually around 25 knots—to keep global supply chains moving. A 12-cylinder version of this engine existed, but the 14-cylinder configuration was the "sweet spot" for the sheer scale of the new generation of post-Panamax vessels.

It’s about torque.

The 14RT-flex96C produces 7,603,850 Newton-meters of torque. That is a number that doesn't even feel real. It’s enough torque to practically rotate the earth if you bolted it to the ground. This massive force allows the ship to turn a single, enormous propeller at very low RPMs—usually between 92 to 102 RPM. Slow and steady wins the race when you're pushing 150,000 tons of cargo through saltwater.

The Maintenance Nightmare

Imagine changing the oil on this. You don't buy a quart at the local shop. You measure it in tons. Everything about the Wärtsilä Sulzer 14RT-flex96C is a logistical feat. Engineers have to literally climb inside the engine for inspections.

Pistons are huge. They wear down. Replacing a single piston liner involves heavy-duty cranes and a crew of specialized technicians working in a space that feels more like a factory floor than an engine room. There's a certain smell in these engine rooms—a mix of hot metal, heavy fuel oil (HFO), and specialized lubricants. It’s the smell of global trade.

One thing people get wrong is thinking these engines run on the same diesel you put in a truck. They don't. They run on "bunker fuel," which is basically the sludge left over after the refining process. It's so thick at room temperature that you can practically walk on it. The 14RT-flex96C has to heat the fuel just to make it liquid enough to pump into the injectors.

✨ Don't miss: Why the Star Trek Flip Phone Still Defines How We Think About Gadgets

The Environmental Elephant in the Room

We can't talk about the Wärtsilä Sulzer 14RT-flex96C without talking about emissions. Shipping is a dirty business. Because these engines burn heavy fuel oil, they release a lot of sulfur oxides (SOx) and nitrogen oxides (NOx).

However, Wärtsilä hasn't just sat on their hands. The "flex" system—that electronic control we talked about—allows the engine to operate in different modes. It can be tuned for low-load fuel economy or for high-speed transit. Newer iterations of this technology are being adapted to run on LNG (Liquefied Natural Gas) or even ammonia and methanol as the industry tries to "decarbonize."

The 14RT-flex96C was a pioneer because it proved that electronics could handle the stresses of a massive maritime environment. Before this, everyone thought electronic sensors would just vibrate to pieces or melt. They didn't. They made the engine smarter.

The Legacy of the King

Is it still the "biggest" engine? In terms of physical dimensions and cylinder count for a single-unit reciprocating engine, it's the gold standard. While there are other massive engines from competitors like MAN Energy Solutions, the 14RT-flex96C remains the poster child for "Mega-Engineering."

It changed how we think about scale. Before this engine, container ships were getting bigger, but their power plants were struggling to keep up. This engine gave naval architects the green light to build even larger hulls because they knew the propulsion was finally available.

Practical Realities for Maritime Enthusiasts

If you’re actually looking into the technical specs for a project or just because you’re a gearhead, keep these three things in mind.

🔗 Read more: Meta Quest 3 Bundle: What Most People Get Wrong

First, look at the Specific Fuel Oil Consumption (SFOC). For the 14RT-flex96C, it's roughly 171 g/kWh at full load. If you're comparing engines, that's the number that tells you how much money the ship owner is burning every hour.

Second, notice the RPM range. Most people are used to engines that rev to 5,000 or 10,000. Here, if you hit 110 RPM, you're in the "red zone." The sheer inertia of a 300-ton crankshaft means you cannot change speeds quickly. It takes miles to stop a ship powered by one of these because you can't just "slam it in reverse" without risking a catastrophic mechanical failure.

Third, consider the lubrication. These are "crosshead" engines. In a car, the piston rod connects directly to the crankshaft. In the 14RT-flex96C, there’s a massive sliding block (the crosshead) between them. This prevents side-loading on the piston, which is why these engines can run for decades. The cylinder lubrication is separate from the crankcase lubrication. It’s a dual-system setup that keeps the "dirty" combustion byproducts away from the "clean" moving parts of the bottom end.

Next Steps for Deeper Insight

If you want to see this machine in its natural habitat, research the Maersk E-Class vessels. Looking at a cross-section diagram of those ships will show you exactly how the engine occupies nearly a third of the ship's height.

For those interested in the future of this tech, keep an eye on Wärtsilä’s 2-stroke ammonia fuel conversion kits. The 14RT-flex96C platform is the foundation for the next twenty years of "green" shipping research. You can't just throw these engines away; you have to evolve them.

The era of the "Mega-Engine" isn't over. It's just getting smarter. While the 14RT-flex96C might seem like a relic of a high-carbon past, its efficiency and electronic control systems are actually the roadmap for how we'll move goods across the ocean in 2030 and beyond. It’s a 2,300-ton bridge between the old world and the new one.