Walk into any vintage hangar and you'll smell it before you see it. That heavy, sweet scent of aerosolized oil and high-octane fuel. It lingers around the massive, circular faces of Boeing Stearmans and Douglas DC-3s. If you’ve ever looked at a radial aircraft engine diagram, you know it looks less like a modern car motor and more like a mechanical flower. It’s a strange, beautiful arrangement of cylinders radiating outward from a central point.

It works. It really works.

Modern jet turbines are sleek and efficient, but they lack the visceral, punching rhythm of a radial. These engines didn't just power the Golden Age of Flight; they defined it. From the buzzing wasps of the 1930s to the massive R-2800 Double Wasps that shoved Corsairs through the Pacific sky, the radial design was the undisputed king of the air.

Cracking the Radial Aircraft Engine Diagram: How It Actually Moves

Most of us are used to the "inline" or "V" engines in our cars. Pistons go up and down in a straight row. Simple. But a radial engine is a different beast entirely. It’s built around a single, central crankcase.

✨ Don't miss: The Real Reason macOS High Sierra 10.13.1 Changed Your Mac Forever

Imagine a clock face. Now, imagine a piston at every odd number. That’s essentially what you’re seeing when you look at a radial aircraft engine diagram.

The secret sauce is the "master and articulating rod" assembly. Unlike your Honda, where every piston has its own spot on the crankshaft, a radial engine has one "Master Rod." This beefy piece of steel connects directly to the crankshaft. All the other rods—called articulating rods—attach to pins on the edge of that master rod.

When the top cylinder fires, it pushes the master rod down. Because the other rods are linked to it, they follow in a circular, wobbling dance. It’s chaotic to look at, but the geometry is precise.

Why the odd numbers?

You’ll almost never see a four-cylinder or six-cylinder single-row radial. Why? It comes down to the firing order. To keep the engine balanced and the power delivery smooth, these four-stroke engines need to fire every other cylinder in a sequence. If you had an even number, the firing order would eventually "overlap" or leave a gap that causes massive vibration. With five, seven, or nine cylinders, the engine can skip a beat perfectly: 1-3-5-7-9-2-4-6-8.

It’s a mechanical leapfrog.

The Battle Between Air and Liquid

Back in the day, engineers like those at Wright Aeronautical and Pratt & Whitney weren't just building engines; they were picking sides in a war. On one side, you had liquid-cooled engines (like the famous Rolls-Royce Merlin in the Mustang). On the other, the air-cooled radial.

Radials won the popularity contest for a few very specific reasons.

First, they’re tough. Like, scary tough. A liquid-cooled engine is vulnerable. One tiny piece of shrapnel punctures the radiator, the coolant leaks out, and the engine seizes in minutes. You’re a glider.

In a radial, there is no radiator. The "cooling system" is just the air rushing over the fins of the cylinders. Pilots in WWII frequently flew home with entire cylinders blown off their radial engines. As long as the master rod stayed intact and the oil kept flowing, those big round hulks would keep spinning.

Secondly, they have a massive power-to-weight ratio. By ditching the heavy radiators, pumps, and gallons of coolant, you save a ton of weight. That’s more room for fuel or ammunition.

The drag problem

Of course, there’s a catch. Look at any radial aircraft engine diagram and you’ll notice the surface area. It’s huge. It’s basically a giant flat plate being pushed through the air. This created immense drag. Engineers eventually solved this with the "NACA Cowling"—that iconic metal ring that wraps around the engine. It directed air through the cylinders for cooling while smoothing out the flow on the outside.

It was a game-changer.

Maintenance Nightmares and "The Gulp"

Talk to a mechanic who works on 1940s radial engines and they’ll probably show you their oily hands. These things leak. It’s not a defect; it’s a lifestyle.

One of the weirdest quirks you'll find in the history of the radial aircraft engine diagram is something called "hydrostatic lock." Because the cylinders sit in a circle, gravity pulls the oil down into the bottom cylinders while the plane is parked.

If you try to start the engine with oil sitting in those lower combustion chambers, you'll snap a connecting rod. Oil doesn't compress.

This is why you’ll see vintage plane owners "pulling through" the prop by hand before starting. They are manually clearing the oil out of the bottom cylinders. If the prop stops dead, they know they’ve got a puddle in cylinder number 5 or 6.

And then there's the fuel consumption. A large radial engine, like the Pratt & Whitney R-4360 Wasp Major (which had 28 cylinders!), didn't just sip fuel. It gulped it. We’re talking hundreds of gallons per hour.

The Modern Legacy of the Round Engine

You might think these engines are museum pieces, but they are still out there working.

Agricultural sprayers (crop dusters) and bush planes in the Yukon still rely on the massive torque of radials. When you need to lift a heavy load off a short, muddy strip, you don't want a high-revving modern engine. You want the low-end grunt of a nine-cylinder radial.

The Wright R-1820 Cyclone is a legend in this space. It powered the B-17 Flying Fortress, and variations of it are still being overhauled today. It’s an engine that refuses to die because its design is fundamentally simple: make it big, keep it cool, and let it breathe.

What You Can Learn from the Diagram

If you're looking at a radial aircraft engine diagram for a project or just out of curiosity, focus on the valve train. In most radials, the valves are operated by a "cam ring" rather than a camshaft.

It’s a large, flat plate with lobes on it that spins much slower than the crankshaft. As it turns, it bumps the pushrods that open and close the valves. It’s an elegant solution to the problem of how to reach cylinders pointing in every direction.

✨ Don't miss: Where Is the Current Location of Magnetic North? Why Your Compass Is Lying to You

Take Action: Exploring Radials Yourself

If this mechanical madness interests you, don't just look at a screen.

- Visit a Living History Flight Experience: Groups like the Commemorative Air Force (CAF) or the Smithsonian National Air and Space Museum offer the best "3D" versions of these diagrams. Seeing an R-2800 with the cowling off is a masterclass in engineering.

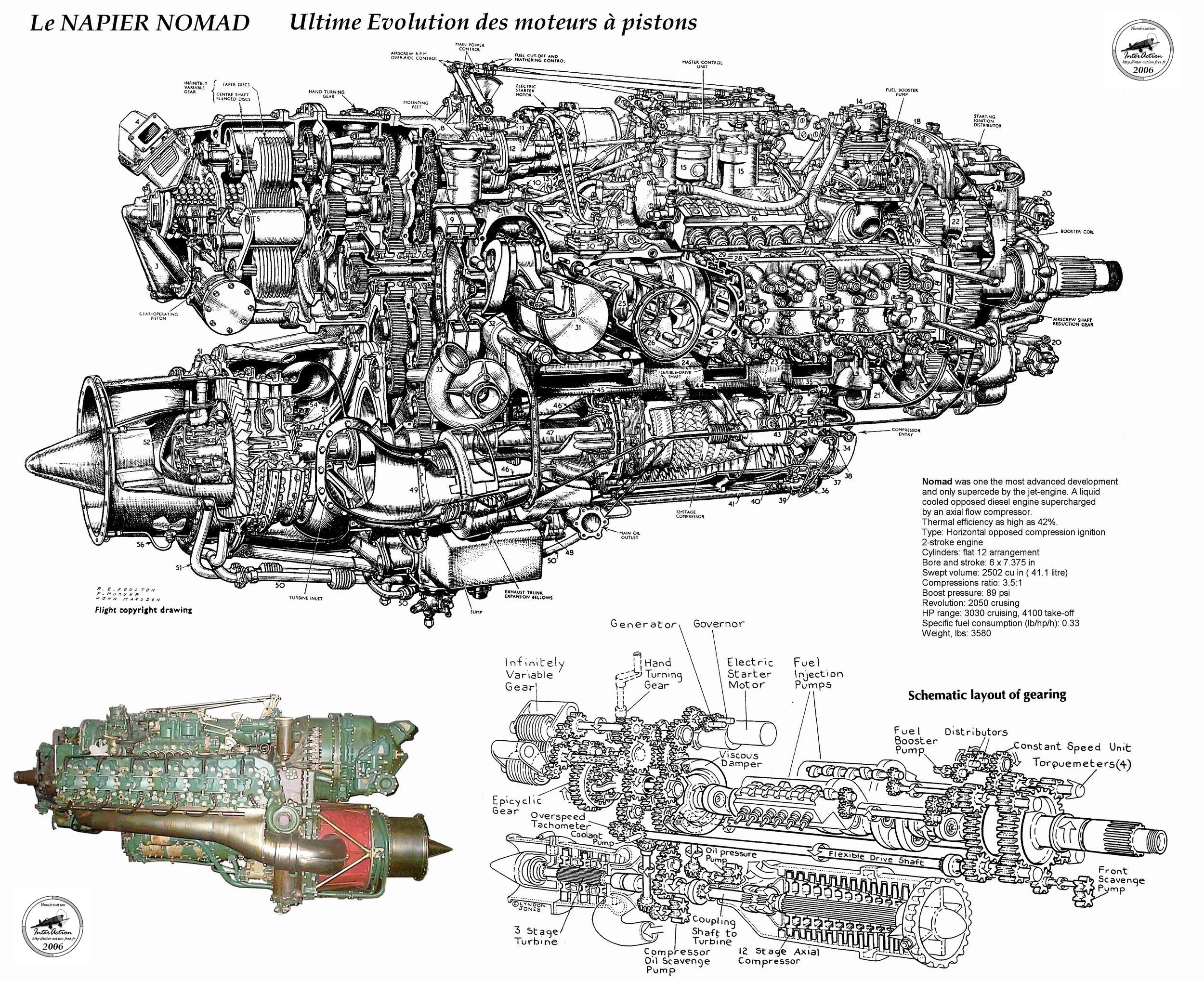

- Study the "Wasp Major" cutaway: If you want to see the peak of this technology, look up the R-4360. It’s four rows of seven cylinders each. They called it the "Corncob." It represents the absolute limit of what reciprocating engines could do before the jet engine took over.

- Flight Simulation: If you use software like MSFS 2020 or X-Plane, try flying the Douglas DC-6. They’ve modeled the engine stresses, including the cooling requirements. It'll teach you more about the practical application of a radial engine than any textbook.

The radial engine is a reminder that the "best" solution isn't always the most aerodynamic one. Sometimes, it’s the one that can take a hit, keep its cool, and provide enough raw power to lift a house into the sky. It’s loud, it’s messy, and it’s a masterpiece of 20th-century grit.