You’ve seen them in old shipyards, hanging from the rafters of a dusty garage, or maybe at the end of a massive construction crane. They look simple. Almost too simple. It’s just a rope looped around a couple of wheels, right? Well, honestly, the pulley block and tackle system is one of the most clever cheats in the history of physics. It is the ultimate "work smarter, not harder" hack that humans figured out thousands of years ago, and we still haven't found a better way to move heavy stuff without breaking a sweat.

Think about trying to lift a 200-pound engine block straight up. Unless you’re an Olympic powerlifter, you aren’t doing it. But with the right arrangement of pulleys, that same 200 pounds feels like 50. Or 25. It’s basically magic, except it’s just geometry and tension playing tricks on gravity.

The mechanical advantage of the pulley block and tackle system

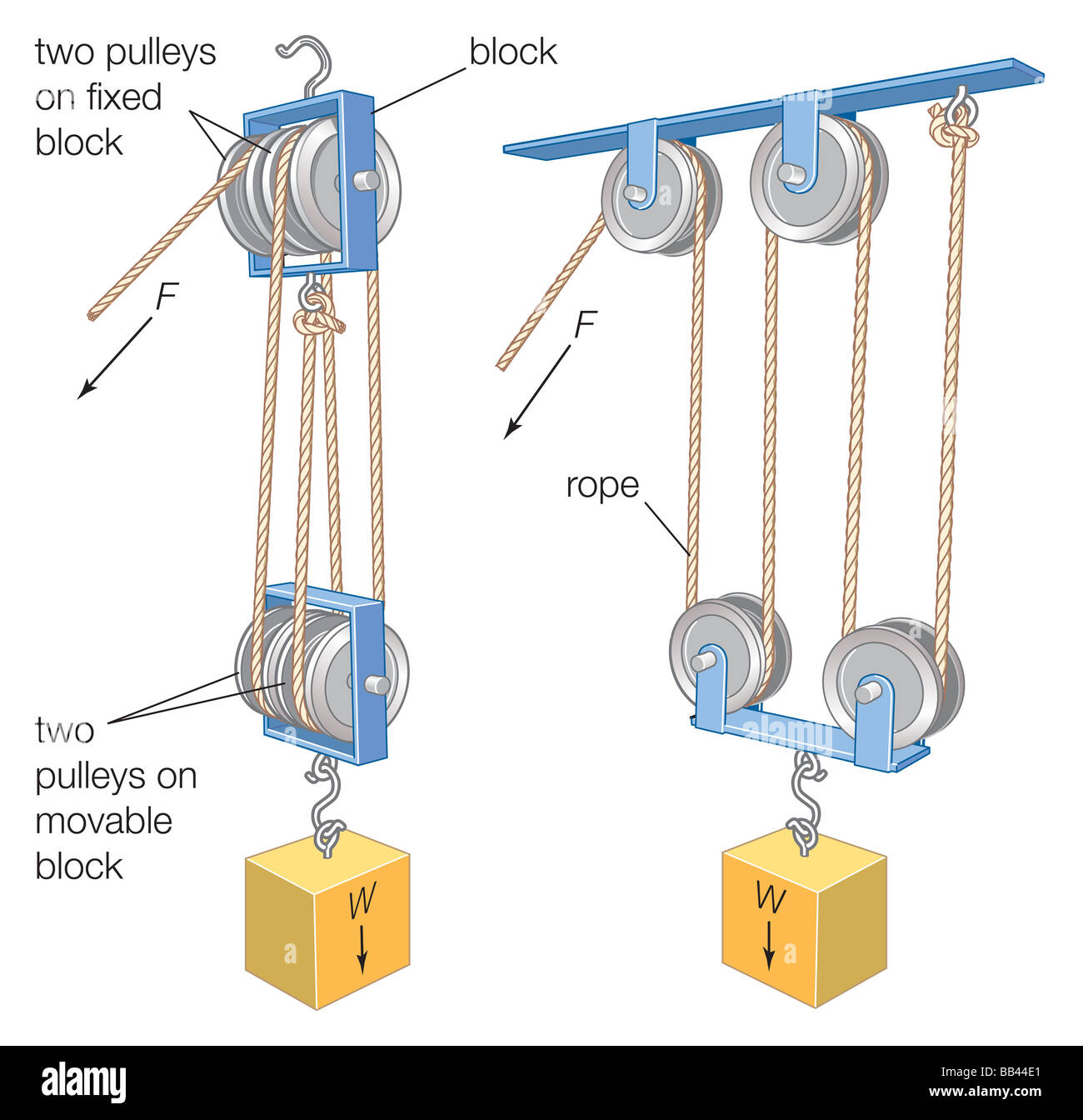

Let's get the big concept out of the way first: Mechanical Advantage (MA). This is just a fancy way of saying how much a tool multiplies your force. In a pulley block and tackle system, the math is tied directly to the number of rope segments supporting the load. If you have two ropes pulling up on a weight, you only have to pull with half the weight's force. Four ropes? You're pulling with a quarter of the force.

But there’s a catch. Physics never gives you something for nothing. You trade distance for ease. If you want to lift a heavy crate 10 feet into the air using a system with a 4:1 mechanical advantage, you have to pull 40 feet of rope. It’s a long walk for a short lift. This is the fundamental trade-off of the block and tackle. You’re doing the same amount of total work—Work equals Force times Distance ($W = F \times d$)—but you’re spreading that force out over a much longer pull.

Most people get confused about where the "block" and the "tackle" actually are. The "block" is the wooden or metal frame that holds the sheaves (the wheels). The "tackle" is the assembly of rope or cable that runs through those blocks. When you put them together, you get a system that can move mountains. Or at least a very stubborn boat.

🔗 Read more: Is Google Have Human Name? The Truth Behind the Brand and Its AI

Why the "moving" block is the real MVP

If you just hang a pulley from a ceiling and loop a rope over it, you’ve made a fixed pulley. This does exactly zero for your lifting power. It has a mechanical advantage of 1. All it does is change the direction of your pull, which is handy if you’d rather pull down than lift up, but you're still hauling the full weight.

To actually gain an advantage, you need a movable block. This is the part of the pulley block and tackle system that is attached to the load itself. When the block moves with the weight, it creates multiple segments of rope that share the burden.

Archimedes is often credited with perfecting this. Legend has it he used a complex series of blocks to single-handedly pull a fully loaded galley ship onto dry land. Whether that's 100% true or a bit of ancient Greek PR, the principle holds up. By increasing the number of sheaves in the blocks, you exponentially decrease the effort required.

Real-world applications that aren't just textbooks

We tend to think of these as "old school" tech, but they are literally everywhere. Sailors are the true masters of the pulley block and tackle system. On a sailboat, these systems are called "purchases." If you’re trying to trim a massive mainsail against a 20-knot wind, your arms aren't strong enough. You need a 4:1 or 6:1 purchase system to tighten that line.

Construction is another one. Look at the "hook block" on a crane. It’s not just a single cable holding that steel beam. It’s a massive block with multiple sheaves, laced with high-strength wire rope. This allows a crane’s motor to lift 50 tons without needing a motor the size of a skyscraper.

- Rock Climbing and Rescue: Climbers use "haul systems" to pull gear up big walls or to rescue an injured partner. They use small, high-efficiency pulleys to create a 3:1 "Z-drag" system.

- Theater and Stagecraft: Those massive curtains and heavy lighting rigs move silently and quickly because of counterweights and—you guessed it—blocks.

- Arborists: When a tree surgeon is cutting down a massive limb over your house, they don't just drop it. They use a block and tackle to lower it slowly and safely.

Friction: The silent enemy of the pulley

If the math says a 4-pulley system makes 400 pounds feel like 100, why does it still feel so heavy in real life? Friction.

No system is 100% efficient. Every time the rope bends over a sheave, and every time that sheave spins on its axle, energy is lost. In a cheap, rusty block and tackle, you might lose 10% or 20% of your effort to friction. This is why high-end blocks use ball bearings or bronze bushings.

There is also a point of diminishing returns. You might think, "Well, I'll just add 20 pulleys and lift a house!" But eventually, the friction from all those wheels and the weight of the extra rope becomes so great that it cancels out the mechanical advantage. Most practical systems cap out around a 6:1 or 8:1 ratio for manual work. Beyond that, the rope starts getting tangled, and the friction becomes a nightmare.

How to "reeve" a block and tackle like a pro

"Reeving" is just the technical term for threading the rope through the pulleys. If you do it wrong, the blocks will twist or the ropes will rub against each other, causing "chafe," which is a fancy word for your rope falling apart.

The best way to reeve a system with multiple sheaves is the "right-angle" method. Instead of going straight through, you turn one block 90 degrees to the other. This prevents the block from tilting (capsizing) when you put it under a heavy load. It keeps the pull centered. If the pull isn't centered, the sheaves rub against the side of the block, and suddenly your 4:1 advantage feels like a 1:1 struggle.

👉 See also: Why the Bluetooth speaker Bose portable remains the gold standard for your kitchen and your campfire

Materials matter: Steel vs. Synthetic

Back in the day, blocks were made of Lignum Vitae—an incredibly dense, oily wood that acted as its own lubricant. Today, we have better options, but the choice depends on the job.

For heavy industrial lifting, steel blocks with wire rope are the standard. They don't stretch. Stretch is the enemy of a pulley block and tackle system. If your rope stretches like a rubber band, you spend the first ten feet of your pull just taking up the "boing" before the load even moves.

For home use or sailing, we use synthetic ropes like Polyester or HMPE (High-Modulus Polyethylene). HMPE is incredible because it has almost zero stretch and is stronger than steel, but it's slippery, so you need blocks specifically designed to grip it.

Misconceptions about "Free Power"

A common mistake people make is thinking that a block and tackle makes them "stronger." It doesn't. You are still providing the same amount of energy. You’re just changing the rate at which that energy is spent.

Think of it like the gears on a mountain bike. Shifting into a low gear doesn't make your legs stronger; it just lets you spin your legs faster to move the bike slowly up a steep hill. The block and tackle is exactly the same. You're "gearing down" gravity.

Practical takeaways for using a block and tackle

If you’re planning to set one of these up in your garage to pull an engine or lift a heavy workbench, keep these specific tips in mind:

- Check the SWL (Safe Working Load): Every block has a rating. If the block is rated for 500 lbs and you're using a 4:1 system to lift 1000 lbs, you aren't just cheating physics; you're asking for a face full of shrapnel when the block shatters.

- Watch the Angle: If you pull at an awkward angle, you’re losing efficiency and risking a side-load failure. Try to keep your pull as straight as possible relative to the blocks.

- Mind the "Becket": The becket is the little loop on the end of the block where the rope is tied off. Ensure your knot (usually a bowline) is rock solid. This is the single point of failure for the whole system.

- Lubrication is King: A drop of 3-in-1 oil or some dry Teflon spray on the axles can literally make a 50-pound difference in how hard you have to pull.

The pulley block and tackle system is a testament to human ingenuity. It's a tool that hasn't changed much in centuries because it doesn't need to. It relies on the rigid laws of the universe to give us a fighting chance against the weight of the world.

📖 Related: How to compress a file on iPhone: The easiest ways to save space right now

To get started with your own system, you should first identify the total weight you intend to lift and then calculate the necessary mechanical advantage, ensuring your rope's breaking strength is at least five times the expected load. Inspect your sheaves for any nicks or burrs that could fray your line, and always perform a "test lift" just a few inches off the ground to check for any twisting or binding in the reeving. Once your setup is verified, maintain a steady, hand-over-hand pulling rhythm to avoid shock-loading the system.