You’ve probably heard the term "World’s Factory" a thousand times. It’s a bit of a cliché. But when you actually stand on the ground in the Pearl River Delta Guangdong, the scale of it hits you in a way that data points on a spreadsheet just can't. We're talking about a massive, sprawling megalopolis that basically eats GDP for breakfast. It’s loud. It’s humid. It’s remarkably efficient.

For decades, this region was the place where your plastic trinkets and cheap t-shirts came from. That’s the old story. The new story is about high-end robotics, electric vehicles (EVs), and a level of hardware integration that makes Silicon Valley look a little bit slow. If you want to build a hardware startup today, you don't go to London or New York. You go to Shenzhen. You go to the Delta.

Honestly, the sheer speed of the place is exhausting.

The Massive Scale of the Greater Bay Area

Geographically, we’re looking at a cluster of cities including Guangzhou, Shenzhen, Dongguan, Foshan, and several others, now formally rebranded by the Chinese government as the "Guangdong-Hong Kong-Macao Greater Bay Area" (GBA). It’s an ambitious attempt to link different legal systems and economies into one cohesive powerhouse.

Think about it this way.

The Pearl River Delta Guangdong region accounts for roughly 10% of China’s entire economy, despite taking up less than 1% of its land mass. That is an absurd concentration of wealth and productivity. When people talk about the "rise of China," this is the engine room they are referring to.

But it isn't just one giant factory. It’s a specialized ecosystem.

- Shenzhen is the tech heart (the "Silicon Valley of Hardware").

- Dongguan and Huizhou handle the heavy lifting of manufacturing.

- Guangzhou remains the trading and logistics hub, a role it has held for centuries as the start of the maritime Silk Road.

- Foshan is where your furniture and appliances probably originated.

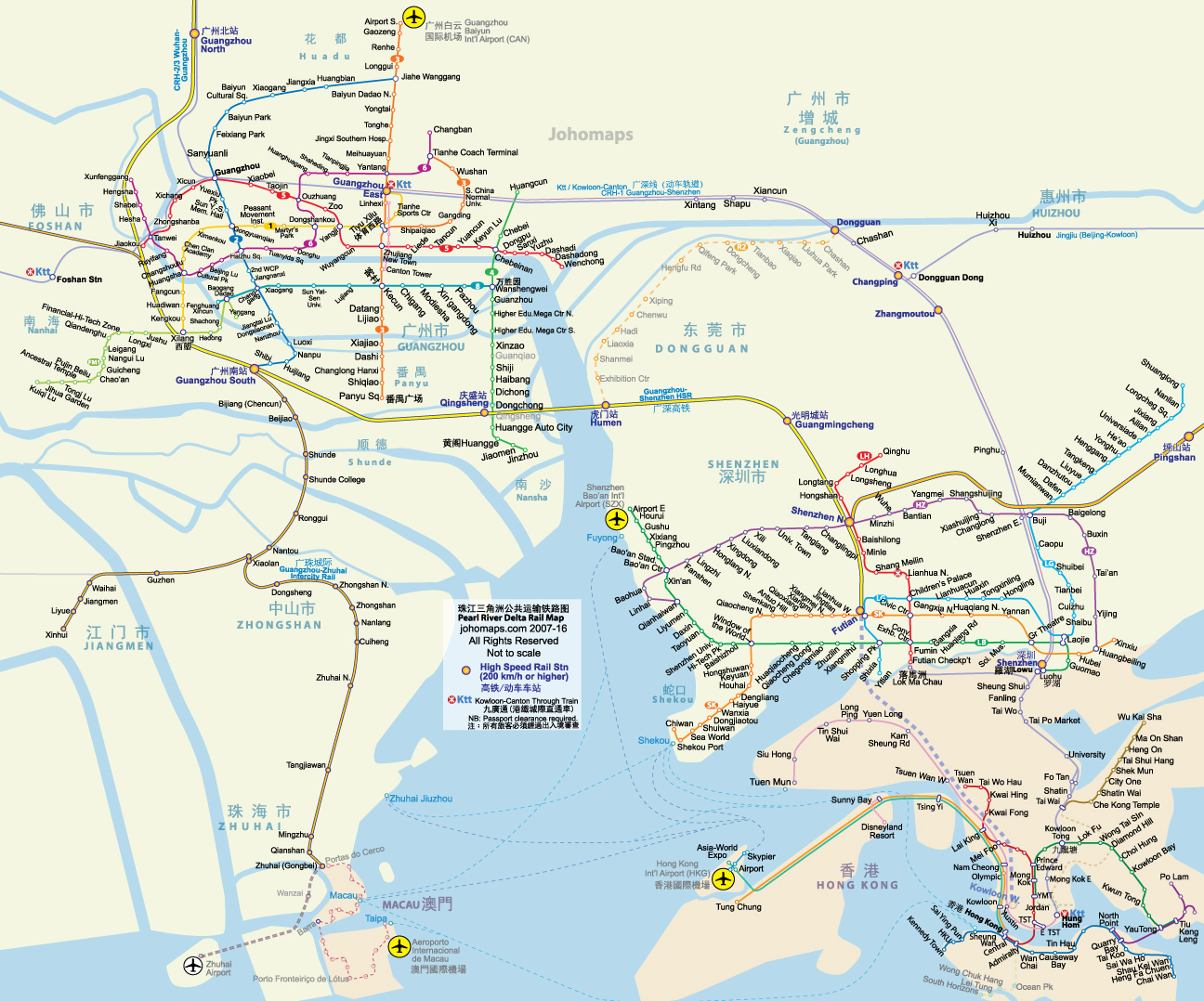

The connectivity is what makes it work. You can take a high-speed train from Hong Kong to Guangzhou in under an hour. That kind of infrastructure turns a collection of separate cities into a single, functional labor market.

📖 Related: GA 30084 from Georgia Ports Authority: The Truth Behind the Zip Code

The Shift From Cheap Labor to High-Tech Dominance

There’s a huge misconception that the Pearl River Delta Guangdong is still just about low-wage labor. That ship sailed years ago. Wages have spiked. Land is expensive. Environmental regulations are actually being enforced now. Because of this, the low-end stuff—stuff like basic garment stitching or simple plastic molding—is moving to Vietnam, India, or Ethiopia.

What’s left behind is the "smart" stuff.

Take DJI, the drone company. They are headquartered in Shenzhen for a reason. They can design a prototype in the morning, find a specialized sensor manufacturer in the afternoon (probably just a few miles away), and have a working model by the next day. This is "Shenzhen speed." It’s a supply chain density that doesn't exist anywhere else on Earth.

According to Dr. Linda Yueh, an economist at Oxford, the clustering effect in the PRD is its greatest competitive advantage. When all your suppliers are within a two-hour drive, your innovation cycle shrinks. You aren't waiting for shipping containers from across the ocean; you're sending a courier on a scooter.

The Reality of Doing Business on the Ground

If you’re a business owner looking at the Pearl River Delta Guangdong, you’ve got to be realistic. The "easy" money is gone. Competition is brutal. Chinese domestic brands are no longer just making "knock-offs"; they are often out-innovating Western counterparts in fields like 5G, battery technology, and mobile payments.

BYD, based in Shenzhen, recently overtook Tesla in global EV sales for certain quarters. That didn't happen by accident. It happened because they sit right in the middle of the world’s most advanced battery supply chain.

But it’s not all sunshine and rapid growth.

👉 See also: Jerry Jones 19.2 Billion Net Worth: Why Everyone is Getting the Math Wrong

The region faces massive demographic headwinds. The workforce is aging. Young Chinese people don't want to work in factories anymore—even "smart" ones. They want to be influencers, coders, or gamers. This has forced a massive push toward automation. If you walk into a modern factory in Dongguan today, you’ll see more Fanuc or Kuka robotic arms than human beings.

Logistics: The Arteries of the Delta

You cannot talk about this region without talking about the water. The Pearl River itself is a muddy, busy highway. The ports of Shenzhen and Guangzhou are consistently ranked among the top five busiest in the world.

The logistics here are a symphony of chaos and precision.

- Huge container ships line up in the South China Sea.

- Feeders bring goods down the river from inland ports.

- The Hong Kong-Zhuhai-Macao Bridge—the longest sea-crossing bridge in the world—connects the east and west banks, slashing travel times from hours to minutes.

It’s an infrastructure flex.

However, there is a tension here. The "One Country, Two Systems" framework that includes Hong Kong and Macao adds a layer of complexity. Customs, different currencies, and different legal codes mean that while the GBA is physically connected, it still faces "soft" barriers that the government is desperately trying to dissolve through digital integration and new trade zones like Qianhai.

Why Quality Control is the New Battleground

One of the biggest complaints about the Pearl River Delta Guangdong used to be quality. "Made in China" was a punchline.

That has changed, but only if you know what you're doing.

✨ Don't miss: Missouri Paycheck Tax Calculator: What Most People Get Wrong

The region operates on a "get what you pay for" philosophy. If you squeeze a supplier on price until they have zero margin, they will cut corners. It’s inevitable. But if you look at the high-end output—Apple’s iPhones are still largely assembled here—the quality is world-class. The sophisticated manufacturers in the Delta are now setting the standards for ISO certifications and precision engineering globally.

Environmental Challenges and the "Green" Pivot

The PRD used to be synonymous with smog.

In the early 2000s, the air was thick, and the river was, frankly, a mess. The provincial government in Guangdong has spent billions trying to fix this. They’ve moved the most polluting industries further inland or shut them down entirely.

Shenzhen was the first city in the world to have a 100% electric bus fleet. Every single taxi in the city is electric. While China as a whole is still the world's largest carbon emitter, the Pearl River Delta Guangdong is being used as a testbed for a "circular economy." It’s a weird paradox: the place that produces the world's "stuff" is also trying to lead the way in sustainable manufacturing because they simply ran out of air and water to burn.

Actionable Insights for Navigating the PRD

If you are looking to source, manufacture, or invest in this region, the playbook has changed. You can't just show up at a trade fair in Guangzhou (like the Canton Fair) and expect to find a golden ticket.

- Focus on Niche Ecosystems: Don't just look at "Guangdong." Look at specific towns. Shunde for appliances. Guzhen for lighting. Dalang for knitwear. The specialization is granular.

- Audit for Automation: When choosing a partner, look at their floor. If they are still relying 100% on manual labor for repetitive tasks, they won't be in business in five years. Look for firms investing in "Industry 4.0."

- Understand the GBA Integration: Use Hong Kong for its legal framework and financial services, but keep your R&D and production in Shenzhen or Dongguan.

- Verify, then Trust: Third-party inspections are still mandatory. Use firms like QIMA or SGS. The "trust" in the Delta is built on rigorous, data-driven verification.

The Pearl River Delta Guangdong is no longer a place for beginners looking for the cheapest possible price. It has evolved into a high-stakes, high-tech hub that requires significant boots-on-the-ground presence and a deep understanding of local supply chain dynamics. It’s complex, it’s expensive, and it remains absolutely indispensable to the global economy.

To stay competitive, businesses must move beyond the "outsourcing" mindset and start viewing the Delta as a partner in high-end technical innovation. The transition from a labor-intensive past to an automated, high-value future is nearly complete, and those who still view it through the lens of the 1990s will quickly find themselves left behind.