If you’ve ever hung a single sheet of 5/8-inch Type X drywall by yourself, you know the pain. Your shoulders burn. Your neck is stiff. By the third room, you’re ready to chuck your tools out the window. That’s usually when people realize their standard drill just isn't cutting it. Enter the DeWalt screw gun 20v. It’s the yellow-and-black workhorse that’s basically become a permanent fixture on commercial jobsites from Seattle to Miami. Honestly, it’s rare to find a professional hanging crew that doesn’t have a pile of DCB205 batteries charging in the corner.

The Brushless Reality of the DCF620

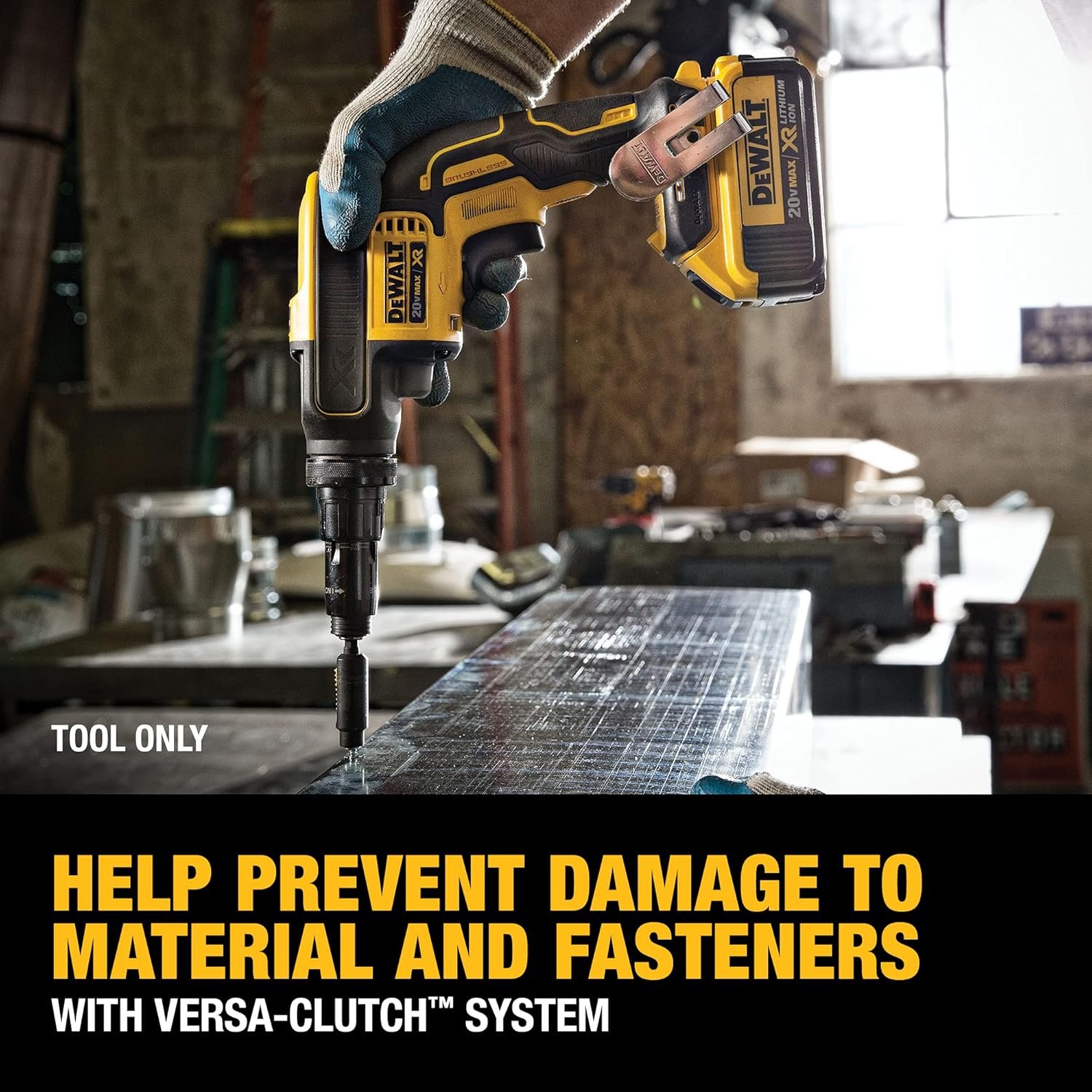

Most people look at the DCF620—that’s the actual model number for the primary 20V MAX brushless drywall screw gun—and think it’s just a drill with a weird nose. It isn't. Not even close.

A standard drill-driver uses a chuck. A screw gun uses a nosecone and a clutch system. When you press the DeWalt screw gun 20v against the rock, the motor engages the bit, drives the screw, and then disengages once it hits a certain depth. It happens in a fraction of a second. The motor is still spinning, but the bit stops. This prevents you from blowing through the paper face of the drywall, which is the cardinal sin of hanging. If you break the paper, the screw has zero holding power. You might as well have not put it in at all.

The brushless motor is the heart of the thing. Old brushed motors were sparks-and-friction machines. They got hot. They died. Brushless tech allows the tool to communicate with the battery, drawing only the juice it needs. It’s more efficient, which is why you can get through nearly 50 sheets of rock on a single 5.0Ah battery charge if you’re moving fast.

Why 4,400 RPM Matters (and Why It Doesn't)

You'll see the 4,400 RPM stat plastered all over the box. It sounds fast. It is fast. But speed without control is just a recipe for stripped heads and wasted screws.

What makes this tool actually usable is the "Cone-Lock" nosecone. It pops off and on without a wrench. This is huge when you inevitably hit a knot in the stud or a metal plate and need to back a screw out. You pull the nose, flip the direction, and you're done.

- Weight: It’s about 3.3 lbs without the battery.

- Ergonomics: The grip is thin. Even if you have smaller hands, you can "palm" the back of the tool to apply direct pressure behind the screw.

- LEDs: There’s a light at the foot. It’s okay. It’s not a floodlight, but it helps when you’re working in a closet before the electricians have finished the rough-in.

Some guys complain that the tool feels "plasticky." Well, yeah. It’s high-impact glass-filled nylon. If it were all metal, your wrist would give out by noon. It’s designed to be light because you’re holding it over your head for eight hours a day.

The Collation Factor: DCF6201

If you really want to talk about speed, we have to talk about the DCF6201 attachment. This is the magazine that turns the DeWalt screw gun 20v into a literal machine gun for screws. You buy screws on plastic strips—usually 50 per strip.

You don't have to reach into your pouch for every single screw. You just push, click, push, click. It’s a rhythmic thing. Professional hangers use this to fly through lids (ceilings). However, there's a learning curve. If you don't keep the tool perfectly perpendicular to the wall, the collated strip will jam. It’s finicky. You have to keep it clean. Dust is the enemy of the magazine.

I’ve seen guys get so frustrated with jams that they throw the attachment across the room. The trick is a quick spray of dry lubricant—never WD-40, which attracts dust like a magnet—into the slide mechanism.

Battery Choices: Power vs. Weight

This is where most DIYers get it wrong. They buy the biggest battery possible, thinking more is better. If you slap a 6.0Ah FlexVolt battery on a DeWalt screw gun 20v, you’re an idiot. Sorry, but it’s true. You’re adding two pounds of unnecessary weight to a tool designed for finesse.

Most pros stick to the 2.0Ah or the newer PowerStack batteries. The PowerStack is a game changer here because it’s flat and light but delivers the punch of a much larger cell. You want the tool to be balanced. If the bottom is too heavy, the nose will want to tip up, making it harder to find your mark.

Common Failures and Real-World Fixes

Nothing is perfect. The DeWalt system has a few quirks that drive people nuts.

First, the nosecone gets clogged with gypsum dust. This makes the depth adjustment "click" stop working. You’ll be trying to set your depth, but the ring won't move. The fix? Take the nosecone off and blow it out with compressed air every single day.

Second, the bit tip. DeWalt uses a specific PR2 bit. It’s not a standard Phillips #2. If you try to use a regular bit, it won't fit the clutch properly or it will sit too deep in the holder. Always buy the specific DeWalt bits designed for the DCF620.

Third, the "locked on" trigger. There’s a button that keeps the motor running so you don't have to pull the trigger for every screw. It’s great for speed, but if you’re not used to it, you’ll end up spinning the bit against the floor or your leg. It takes practice to get the "tap-and-go" rhythm down.

Metal Studs vs. Wood Studs

If you’re doing commercial work with light-gauge metal studs, this tool is your best friend. The 4,400 RPM is perfect for piercing the steel quickly. But if you’re working with heavy-gauge structural steel, you’re going to struggle. This isn't an impact driver. It doesn't have the torque to force a screw through 14-gauge steel without burning out the motor or snapping the bit. For that, you actually want a slower, high-torque corded gun or a dedicated metal-to-metal fastener.

The Competition

Milwaukee has the M18 FUEL. Hilti has the Nuron line. Both are incredible tools. The Hilti, in particular, is often considered the "Ferrari" of screw guns. But it costs twice as much. For most people—from the guy finishing his basement to the contractor running a crew—the DeWalt screw gun 20v hits the "sweet spot" of price and performance. You can find them at any big-box store, and parts are everywhere. If your Hilti breaks, you might be waiting two weeks for a mail-in repair. If your DeWalt breaks, you drive ten minutes to Home Depot and buy a replacement to finish the job.

Expert Tips for Longevity

- Check your depth early: Don't wait until you've hung three sheets to realize your screws are too deep. Test on a scrap piece. The screw head should be slightly below the surface, creating a "dimple," but the paper should be intact.

- Clean the Clutch: Once a month, if you're a heavy user, take the nose off and wipe down the bit holder. Dust buildup here causes the clutch to slip or stick.

- Don't Overheat: If the tool feels hot to the touch, give it five minutes. Brushless motors handle heat better, but they aren't invincible.

- Use the Belt Hook: It sounds stupid, but these tools get dropped all the time. The belt hook is sturdy. Use it. A four-foot drop onto concrete can crack the housing or knock the internal alignment out of whack.

The DeWalt screw gun 20v isn't just a tool; it's a specialized instrument. It’s like a chef’s knife. Sure, you can cut a steak with a pocket knife, but the chef’s knife makes the job effortless. Once you get the hang of the depth setting and the "lean-in" technique required to engage the clutch, you’ll never go back to using a standard drill for drywall.

Actionable Next Steps

If you're ready to pick one up, don't just buy the bare tool if you're new to the platform. Look for the "DCK263P2" kit. It usually includes the screw gun and the XR 20V impact driver, which is a perfect combo. You use the screw gun for the rock and the impact driver for the framing and the heavy-duty fasteners.

If you already own the gun and it's acting up, start by replacing the bit. 90% of "broken" screw guns are just worn-out bits that aren't grabbing the screw head anymore. After that, check the nosecone for packed-in drywall mud. Dig it out with a small screwdriver.

Finally, invest in a 2-pack of the 1.7Ah PowerStack batteries. The weight savings will save your shoulders more than any gym routine ever could. You’ll work faster, stay cleaner, and your finished walls will look like a pro did them—because you used the tool the pros use.

Keep your nosecone clean and your bits fresh. That's the secret.

Summary of Key Specs for the DCF620

- Max RPM: 4,400

- Drive: 1/4" Hex

- Tool Length: 10.75 inches

- Weight: 3.3 lbs (Tool Only)

- Feature: Optional collated attachment (DCF6201)

- Motor: Brushless

Check your local supplier for the latest 2026 pricing, as rebates often drop during the summer building season. Stick with the XR line for the extended warranty. It's worth the extra twenty bucks.