Heat is the enemy. If you’ve ever touched a high-powered flashlight or stood under a stadium light for too long, you know that smell of slightly toasted electronics. That’s the sound of a standard LED crying for help. But the cob square led chip is different. It’s basically the heavy lifter of the lighting world, packing dozens of light-emitting diodes into a tiny, square-shaped footprint that manages to stay cool while pumping out blindingly bright light.

Honestly, the tech is deceptively simple.

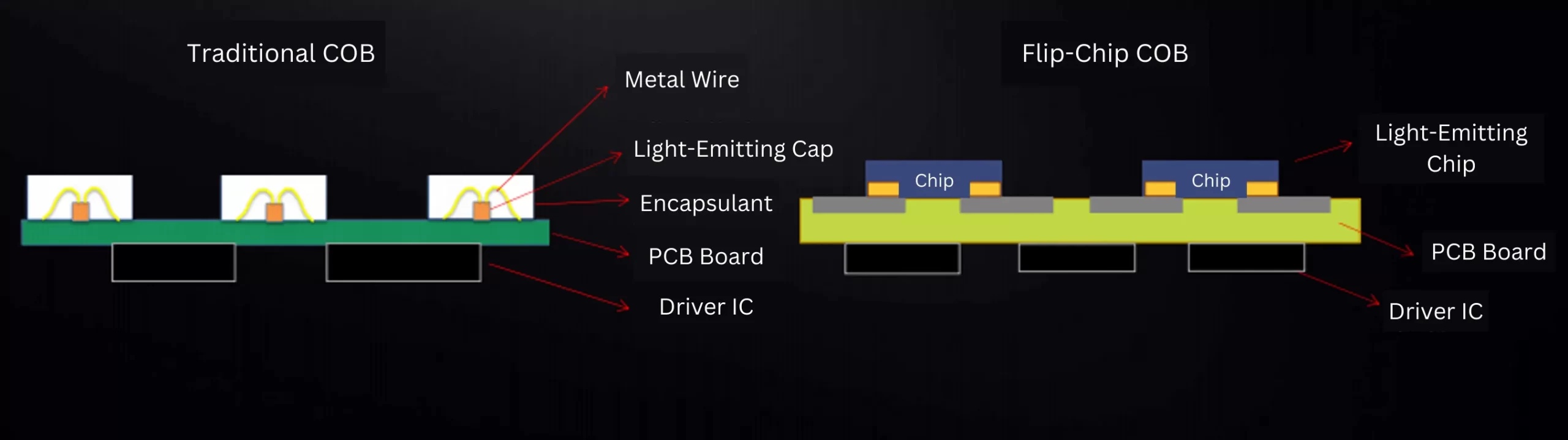

Chip on Board (COB) technology eliminates the individual housing for every single diode. Instead of having a bunch of plastic-encased LEDs soldered onto a board, manufacturers take the raw silicon chips and mount them directly to a substrate. That substrate is usually ceramic or aluminum. Why? Because metal and ceramic are great at sucking heat away from the chip before it melts itself into a silicon puddle.

👉 See also: Beats Solo 3 Gray Explained: Why This Color Still Wins

Most people look at a cob square led chip and just see a yellow square. But if you look closer—or use a macro lens—you’ll see a dense forest of wire bonds and light-emitting points all working in unison. It’s not just one big light; it’s a tiny city of lights sharing a single neighborhood.

What actually makes the cob square led chip better than SMD?

You’ve seen SMDs everywhere. Those are the Surface Mounted Devices—the little white rectangles with the yellow circles inside that you find on cheap LED strips. They’re fine for your under-cabinet lighting. They’re great for your TV remote. But for serious lighting? They’re kinda weak.

The biggest advantage of a cob square led chip is the "light density." Because the chips are mounted directly to the board, you can fit way more of them into a square centimeter than you ever could with SMD tech. This creates a "uniform" light source. Think about the difference between a showerhead with five big holes and one with five hundred tiny ones. The one with five hundred holes feels like a solid wall of water. That’s what a COB chip does with photons.

You don't get those weird multi-shadows. You know the ones—where you hold your hand under a light and see four different shadows overlapping? That’s the mark of a poor LED layout. With a high-quality square COB, you get one clean, crisp shadow because the light is coming from a single, concentrated point.

It’s about thermal resistance, too.

In a standard LED, the heat has to travel through the chip, through the solder, through the lead frame, and finally into the heat sink. That’s a long road. In a cob square led chip, the path is shorter. Direct contact means the heat leaves the chip almost instantly. This is why these chips can run at 50, 100, or even 500 watts without exploding, provided you’ve got a big enough chunk of aluminum behind them.

The weird physics of the square format

Why square? It seems like a boring choice. Circles are more natural for lenses, right?

Well, it comes down to manufacturing efficiency and "waffle" packing. Silicon wafers are circular, but we cut them into squares because it wastes less material. When you’re building an array, a square layout allows for perfectly even spacing of the individual "dice" (the tiny LED bits). This ensures that no single spot on the board gets hotter than the others. If you had a bunch of circles packed together, you’d have these awkward gaps where heat could build up or light wouldn’t be emitted.

✨ Don't miss: Why Download Spotify Playlist to MP3 is Harder Than It Used to Be

Engineering is often just the art of managing compromises.

Companies like Cree and Bridgelux—real titans in this space—have spent millions of dollars perfecting the phosphors that sit on top of these square chips. That yellow stuff you see? It’s not just paint. It’s a chemical slurry designed to turn blue light into white light. If that layer isn't perfectly even across the square, the light will look "fringed"—maybe a bit yellow in the middle and blue on the edges. That's why high-end cob square led chip designs use a very specific dam-and-fill method to make sure the phosphor is flat as a pancake.

Where these chips actually live (and why you should care)

If you’re a photographer or a videographer, you likely own a few of these. High-end studio lights from brands like Aputure or Godox rely almost exclusively on the cob square led chip. They need a point-source of light that can be easily modified with a softbox or a Fresnel lens.

But it's not just for creatives.

- High-Bay Industrial Lighting: Those massive lights hanging from the ceiling in Costco or a gym? Usually COB. They need to throw light from 30 feet up and hit the floor with enough intensity to read a label.

- Street Lighting: Many cities are moving away from the old "corn cob" style LEDs (which look like a literal ear of corn covered in SMDs) to a single, powerful square COB behind a high-quality lens. It’s easier to maintain and lasts longer.

- Architecture: Think about those sharp beams of light that highlight the columns on a fancy hotel. That's a "spot" beam, and you can only get that kind of tight focus with a small, powerful COB chip.

The downside no one mentions

Nothing is perfect. I’d be lying if I said the cob square led chip was the end-all-be-all for every situation.

There’s the "single point of failure" problem. If a single diode in an SMD strip dies, the rest usually stay on. If something catastrophic happens to the substrate of a COB chip—like a massive thermal shock—the whole thing goes dark. It’s all or nothing.

Also, they are incredibly bright. Like, "don't look at it or you'll see spots for twenty minutes" bright. Because the light is so concentrated, the glare can be a real issue if the fixture isn't designed correctly. You can’t just stick a bare cob square led chip on a wall and call it a day. You need optics. You need diffusers. You need engineering.

What to look for when buying or spec-ing

If you're looking at a spec sheet for a cob square led chip, don't just look at the wattage. Wattage is just how much power it sucks from the wall; it doesn't tell you how much light you're getting. Look for the "Lumens per Watt" (lm/W).

A cheap, no-name chip might give you 80 lm/W. A top-tier chip from someone like Citizen or Luminus might push 140 or 160 lm/W. That difference is huge. It’s the difference between a light that runs warm and a light that runs dangerously hot.

Pay attention to the CRI (Color Rendering Index) too.

📖 Related: Neil Armstrong's Space Suit: What Most People Get Wrong

If you’re using these for anything where color matters—like a kitchen, a closet, or a workshop—you want a CRI of at least 90. Cheap square COBs often have a CRI of 70 or 80, which makes everything look slightly grey or sickly green. You’ve probably been in a parking lot at night where everyone’s car looks the same shade of muddy brown; that’s low CRI lighting in action.

Practical Steps for Implementation

If you are actually planning to build something with a cob square led chip, do not skip the thermal paste. It sounds like a small detail, but it’s the bridge between the chip and the world.

First, ensure your heat sink is rated for at least 20% more wattage than your chip. If you have a 50W chip, get a 60W or 70W heat sink. Airflow is your best friend. Even a tiny, silent fan can drop the temperature of a COB chip by 30 degrees, which can literally double its lifespan.

Second, check your driver compatibility. These chips aren't like lightbulbs; you can't just plug them into a socket. They need "constant current" drivers. If you try to run them on a standard "constant voltage" power supply, they will go into "thermal runaway." The chip gets hot, which makes it draw more current, which makes it hotter, until—pop—it's over.

Finally, consider the optics. A bare square chip has a beam angle of about 120 degrees. That’s very wide. If you want to actually aim the light, you’ll need a reflector or a TIR (Total Internal Reflection) lens specifically sized for the light-emitting surface (LES) of your particular cob square led chip.

The technology isn't slowing down. We're seeing "Tunable White" COBs now, where two different sets of diodes—one warm, one cool—are interlaced on the same square substrate. It allows you to change the color temperature of a room from a cold daylight to a warm sunset glow without changing the fixture. It’s complex, it’s efficient, and honestly, it’s the most logical way to light the modern world.