If you’ve been following the news lately, you’ve heard the term. It’s everywhere. Pundits talk about it like it’s the only thing that matters in modern warfare, and honestly, they aren't that far off. We are talking about the 155 mm howitzer shell. It is a heavy, steel-cased beast that weighs roughly 100 pounds. It's essentially the gold standard of NATO artillery.

Why 155? It’s a bit of a historical fluke that turned into a global requirement. Back in the day, the French developed the 155mm Creusot during World War I, and because it hit that "sweet spot" between being portable enough to move and powerful enough to level a building, it stuck. Now, it’s the universal language of big guns.

What actually makes a 155 mm howitzer shell work?

Most people think of a shell as just a giant bullet. That’s wrong. A 155 mm howitzer shell is a complex modular system. You have the projectile itself, which is the part that flies through the air. Then you have the fuse, which sits on the nose and decides when the thing blows up. Below that, you’ve got the propellant—bags or canisters of "powder" that provide the oomph to kick the shell out of the barrel.

The versatility is what makes it scary.

You can swap the fuse out in minutes. Want it to explode the second it touches a tank? Use a point-detonating fuse. Want it to spray shrapnel over a trench? Use a proximity fuse that triggers 20 feet above the ground. There are even "delay" fuses that let the shell bury itself three feet into the dirt before detonating, which is how you collapse bunkers.

The range is another factor. A standard M107 high-explosive shell can reach out about 14 miles. But if you use "Base Bleed" technology—where a small grain of gas-producing material at the bottom of the shell reduces vacuum drag—you can push that to 18 or 20 miles. Then there's the M982 Excalibur. It's a GPS-guided version that can hit a trash can from 25 miles away. It costs over $100,000 per shot, but it rarely misses.

🔗 Read more: Why Extract Music From Video Is Harder Than It Used To Be

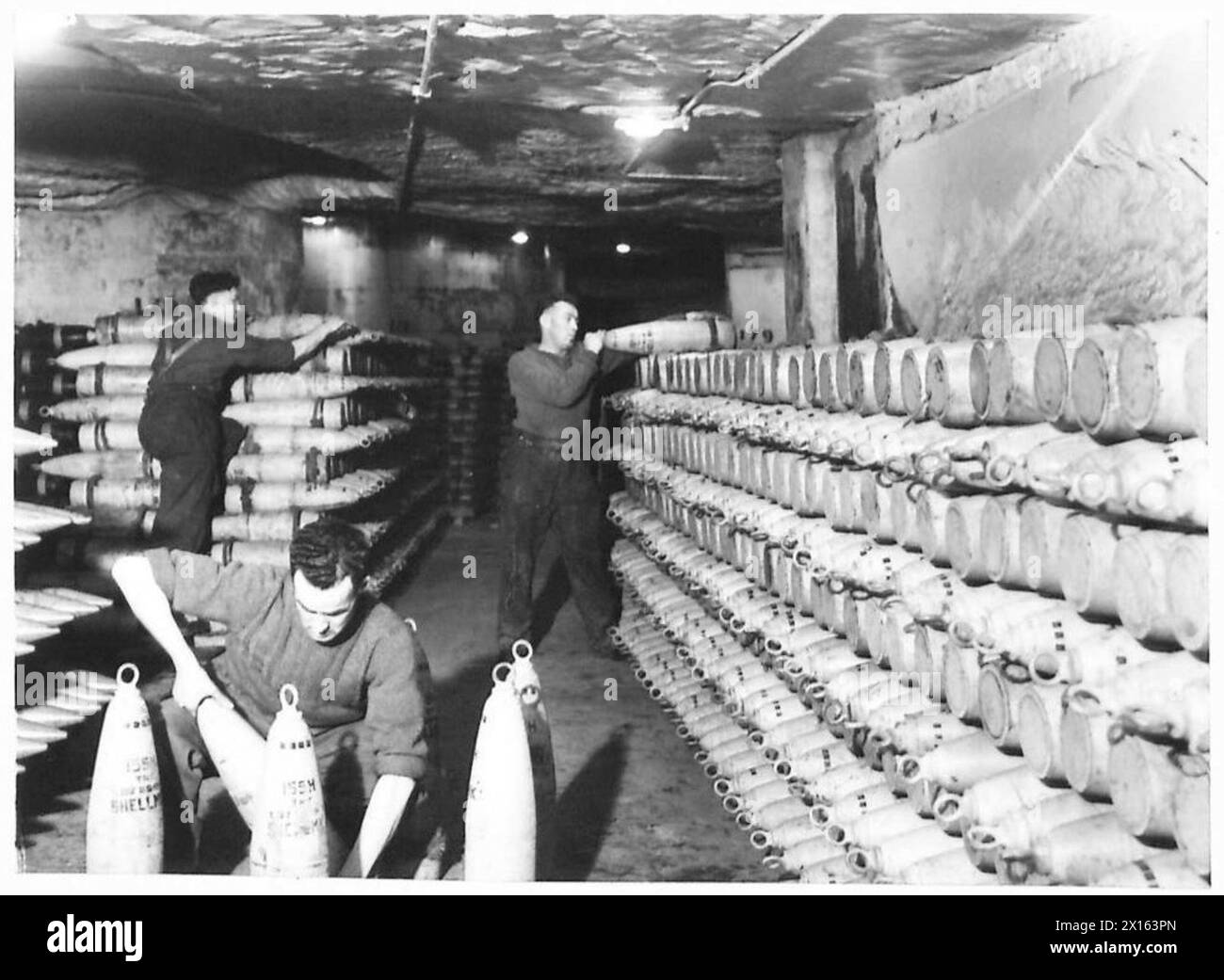

The logistics nightmare nobody talks about

Production is the bottleneck. You can't just 3D print these things. Making a 155 mm howitzer shell requires high-grade forged steel. It requires specialized factories that can heat-treat that steel so it doesn't shatter inside the gun barrel. If the shell body has even a tiny microscopic crack, the pressure of the blast—which is immense—will cause it to explode prematurely.

That's a bad day for the crew.

Then there is the explosive filler. Most 155mm rounds use TNT or Composition B. You have to melt the explosive, pour it into the shell, and let it cool without forming any air bubbles. If there's a bubble, the "set-back" force of firing can cause the explosive to shift and detonate instantly.

Companies like General Dynamics in the U.S., Rheinmetall in Germany, and BAE Systems in the UK are currently racing to increase production. Before 2022, the U.S. was making maybe 14,000 of these a month. Now, the goal is closer to 100,000. That’s a massive industrial leap that requires new robotic assembly lines and a steady supply of precursors like nitric acid.

Not all shells are created equal

It's easy to get confused by the jargon. Let's break down what's actually being fired right now:

- M107 High Explosive (HE): The old reliable. Cheap, effective, lots of steel fragments.

- M795: The modern version of the HE shell. It carries more explosives and has a longer range.

- DPICM: These are "cluster" munitions. One shell opens up in mid-air and drops 88 smaller sub-munitions. They are controversial because of "duds" that don't explode, but they are incredibly effective against spread-out infantry.

- Illumination rounds: Basically a giant flare on a parachute that lights up the night sky for several minutes.

- Smoke rounds: Used to mask movements or mark targets for aircraft.

Why the "Standard" 155 mm is changing

We are seeing a shift toward "smart" shells. The 155 mm howitzer shell is evolving from a "dumb" area-of-effect weapon into a precision strike tool. Take the German SMArt 155 or the Swedish BONUS round. These are "carrier" shells. They fly over a target area, release two sub-munitions that deploy parachutes or winglets, and use infrared sensors to find a tank. Once they spot one, they fire an explosively formed penetrator (EFP) straight down through the thin top armor of the vehicle.

It's a one-shot, one-kill system.

But there’s a trade-off. Precision is expensive. In a high-intensity conflict, you need volume. If you have 10,000 "dumb" shells, you can suppress an entire frontline. If you only have 50 "smart" shells, you're a sniper who’s going to run out of ammo real fast. Military planners are currently arguing over this balance. Do you buy the $800 "cheap" shell or the $100,000 "smart" one? Usually, the answer is "both," but the budget never agrees.

The physical toll on the hardware

Firing a 155 mm howitzer shell isn't like shooting a rifle. Every time a round goes off, it creates a massive amount of heat and friction. This literally "eats" the inside of the howitzer's barrel. This is called "barrel life."

A typical M777 howitzer might only be able to fire 2,500 rounds before the barrel is so worn down that the shells start wobbling in flight, losing all accuracy. If you're firing hundreds of rounds a day, you're burning through barrels every few weeks. This creates a secondary logistics loop: you don't just need more shells; you need a constant stream of replacement chrome-lined steel barrels and the mechanics to swap them out in the field.

Practical takeaways for understanding the 155mm landscape

If you want to keep up with why this specific piece of tech is dominating global defense strategy, keep these points in mind:

- Quantity has a quality all its own. Even with high-tech drones, the sheer weight of fire from 155mm artillery remains the primary way ground is taken or held.

- Interoperability is king. Because of NATO standards, a shell made in a factory in South Korea can be fired from a gun made in the United States and used by a crew in Poland. This is a massive strategic advantage that "non-standard" calibers like the Russian 152mm don't always share as seamlessly.

- The "Kill Chain" is shrinking. Drones act as the eyes, spotting targets and feeding coordinates to the guns in seconds. This makes the 155mm round far more lethal than it was in the 1990s.

- Watch the supply chain. The real "war" is happening in factories in places like Scranton, Pennsylvania, and Unterlüß, Germany. The ability to produce the steel and the explosives is currently the most significant bottleneck in global security.

For those looking to dive deeper into the technical specifications, researching the Joint Ballistics Memorandum of Understanding (JBMoU) is the best move. It’s the boring, technical document that ensures all NATO 155mm ammunition and weapons are actually compatible. Without it, the modern artillery landscape would be a disorganized mess of proprietary parts.