You’re standing in a muddy field, looking at a roll of woven wire and wondering why on earth people still use those green metal stakes. Honestly, it’s a fair question. With all the high-tech composite materials and fancy pressurized woods available now, the humble t post for fencing looks a bit like a relic from your grandfather’s era. But here is the thing: they work. They’re cheap. And if you’ve ever tried to dig forty post holes in rocky soil during a July heatwave, you’ll realize that "pounding steel" is a heck of a lot better than "digging graves" for wooden 4x4s.

Steel matters. Specifically, the high-strength rail steel that goes into most quality posts. Most of what you find at stores like Tractor Supply or local co-ops is made from recycled rail tracks. That’s why they’re so stiff. If you try to bend a heavy-duty t-post, you’re going to lose that fight.

The Anatomy of a T Post for Fencing

People think a post is just a post. It's not. Look at the "studs" running down the spine. Those little bumps aren't decorative; they are what keep your wire from sliding down to the dirt the second a cow leans on it. Then you have the anchor plate—that flat shovel-looking piece at the bottom.

Without that plate, your fence is basically a suggestion. The plate provides lateral stability. When the wind howls or a horse pushes against the line, that plate engages the soil to prevent the post from leaning. If you're installing these in literal solid rock, some guys actually grind the plates off, but for 99% of us, that plate is the only thing keeping the fence upright.

Weight is the secret metric. You’ll see them labeled as 1.25 or 1.33. That’s the weight in pounds per linear foot. A 1.25-pound post is fine for a garden or maybe some lightweight poultry netting. But if you are building a perimeter for cattle or trying to keep deer out of an orchard? You want the 1.33. It’s thicker. It handles the tension of high-tensile wire without bowing like a pool noodle.

Why Wood Often Fails Where Steel Wins

Wood rots. It doesn't matter how much CCA or ACQ chemical treatment they pump into a pine post; eventually, the microbes in the soil win. In wet climates like the Pacific Northwest or the humid Southeast, a wooden line post might give you fifteen years if you’re lucky. A galvanized or high-quality painted t post for fencing can easily sit in the ground for thirty years without flinching.

💡 You might also like: Dutch Bros Menu Food: What Most People Get Wrong About the Snacks

The installation speed is the real kicker. Using a manual post driver—basically a heavy steel tube with handles—you can set a post in about sixty seconds. Try doing that with a power auger and a bag of Quikrete. You can't. Plus, if you mess up the alignment, you just pull the steel post out with a jack and move it. Wood is a permanent commitment to a mistake.

Real World Costs and What to Expect

Let's talk money because that’s usually why we're all here. In the current market, a standard 6-foot t-post fluctuates between $5.00 and $8.00 depending on the steel market and where you live. Compare that to a treated 4x4 wood post which can run $12.00 to $18.00.

When you multiply that by a few hundred feet of fence, the savings are massive. But don't go too cheap. The unpainted, light-duty posts you find at big-box hardware stores for "bargain" prices are often made of inferior steel that will rust through at the soil line within five years. Look for the "Made in USA" stamp from companies like Chicago Heights Steel. They use the real-deal rail steel.

Choosing the Right Height

Don't buy 5-foot posts for a 4-foot fence. You need to bury at least 18 to 24 inches of that post to hit the "sweet spot" of stability.

- For a standard 48-inch woven wire fence, buy 6-foot posts.

- For deer exclusion (usually 6 to 8 feet high), you’re looking at 10-foot heavy-duty steel.

- For a simple silt fence or temporary garden barrier, the 5-footers are fine.

The Clipping Nightmare (And How to Avoid It)

The biggest gripe people have with a t post for fencing is the clips. You know the ones—those little wire "u" shapes that you have to twist with a screwdriver. They’re a pain. They poke your fingers. They fly off into the grass, never to be seen again.

📖 Related: Draft House Las Vegas: Why Locals Still Flock to This Old School Sports Bar

Expert tip: Buy a dedicated t-post clip tool. It’s a $10 piece of metal that makes the twisting motion a one-second job. Also, don't over-tighten them. You want the fence wire to be able to slide through the clip slightly. This allows the fence to distribute the impact if a limb falls on it or an animal hits it. If you cinched it down tight, the wire will just snap or the post will bend.

Common Blunders That Ruin Fences

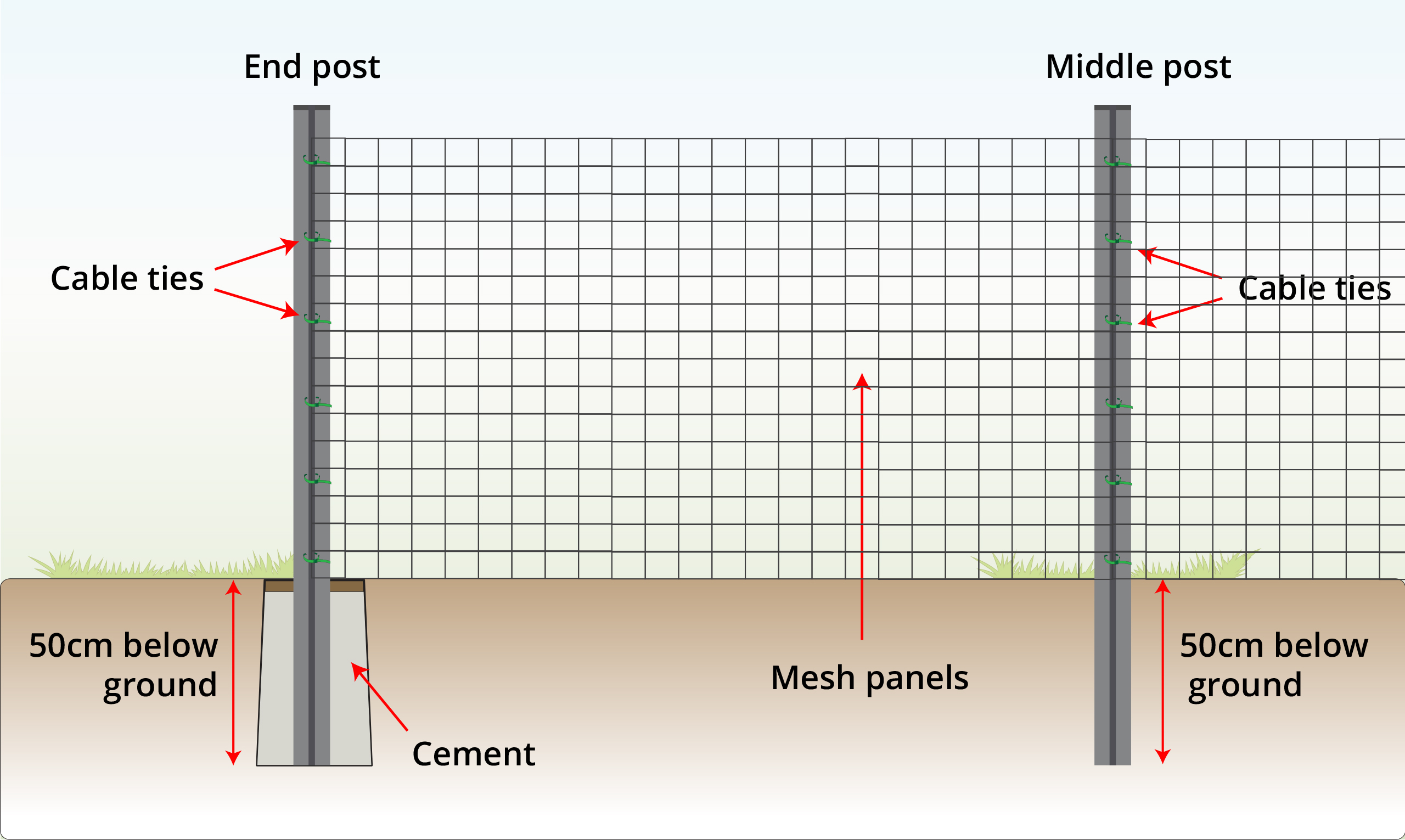

One: Putting t-posts at corners. Don't do it. A t post for fencing has zero structural integrity when it comes to "pull" tension. Your corners and ends MUST be heavy wood posts (6-inch diameter minimum) or "H-braces" made of pipe. The t-posts are just there to hold the wire up between those solid anchor points.

Two: Facing the studs the wrong way. Always point the studs toward the animals. If the livestock pushes against the fence, they are pushing the wire into the post, not away from the clips. It sounds simple, but you'd be surprised how many miles of fence are built backward every year.

Three: Skipping the safety cap. If you have horses, t-posts are dangerous. A horse that decides to "play" near the fence can easily get impaled on the sharp steel top. Use the plastic safety caps. They're cheap, usually bright yellow or white, and they save lives.

Maintenance and the "Rust" Factor

Eventually, even the best paint chips. When the green paint starts to flake, you’ll see orange spots. Most people just ignore it. If you’re a perfectionist, you can hit them with a can of Rust-Oleum every few years, but honestly, the surface rust on a heavy rail-steel post takes decades to compromise the structural integrity.

👉 See also: Dr Dennis Gross C+ Collagen Brighten Firm Vitamin C Serum Explained (Simply)

In high-salt environments—like right on the coast—skip the painted posts entirely. You need hot-dipped galvanized steel. They cost a couple of dollars more per post, but they won't disintegrate in the salty air.

Strategic Next Steps

If you are ready to get started, don't just go buy 100 posts. Start by flagging your line. Use a string line to make sure your row is actually straight, because a "zig-zag" t-post line is an eyesore you'll have to look at for twenty years.

Once your line is flagged, go to your local farm supply store and buy two different weights—a 1.25 and a 1.33. Drive them both into your specific soil. You’ll feel the difference immediately. If your ground is rocky, the 1.33 is non-negotiable; the lighter ones will just "corkscrew" or mushroom at the top when you hit a stone.

Inventory your tools before you start. You need a post driver, a pair of fencing pliers (the ones that look like a hammer and a parrot had a baby), and a box of clips. If you’re doing more than an acre, rent a gas-powered post driver. Your shoulders will thank you, and what would have been a three-day project becomes a four-hour afternoon. Get the heavy steel, point the studs the right way, and your fence will probably outlast your mortgage.