Walk into any refinery in Texas or a massive power plant in Germany and you’ll see them. Huge, cylindrical metal beasts. They aren't exactly "new" tech. In fact, the basic physics behind a shell tube heat exchanger has been understood for over a century. Yet, despite the rise of fancy plate heat exchangers or 3D-printed thermal solutions, these behemoths remain the backbone of global industry. Why? Because they are tough. Like, "survive a chemical plant explosion" kind of tough.

Basically, you’re looking at a large vessel—the shell—packed with a bundle of smaller tubes. One fluid flows through the tubes, and another flows over them inside the shell. Heat moves through the tube walls. It sounds simple. It is simple. But the engineering required to keep these things from vibrating themselves to pieces or leaking toxic chemicals is where the real magic happens.

💡 You might also like: Two Thousandths of an Inch: Why This Invisible Measurement Runs Your Entire World

The Real Reason We Use Shell Tube Heat Exchangers

Efficiency isn't always about being the sleekest. In the world of high-pressure steam or volatile hydrocarbons, efficiency is about not breaking down every six months. Plate exchangers are great for space-saving, sure. But if you’ve got a fluid that's basically liquid sandpaper (slurry) or something that operates at 500°C, a plate exchanger is going to fail. Fast.

The shell tube heat exchanger thrives in the chaos. It handles pressures that would make other designs buckle. We're talking upwards of 30 megapascals in some specialized chemical processes. Plus, if a tube leaks? You can often just plug it. You don't have to throw the whole unit away. You just open the header, find the offender, and weld it shut. Try doing that with a brazed plate unit. You can't.

It's all about the TEMA standards

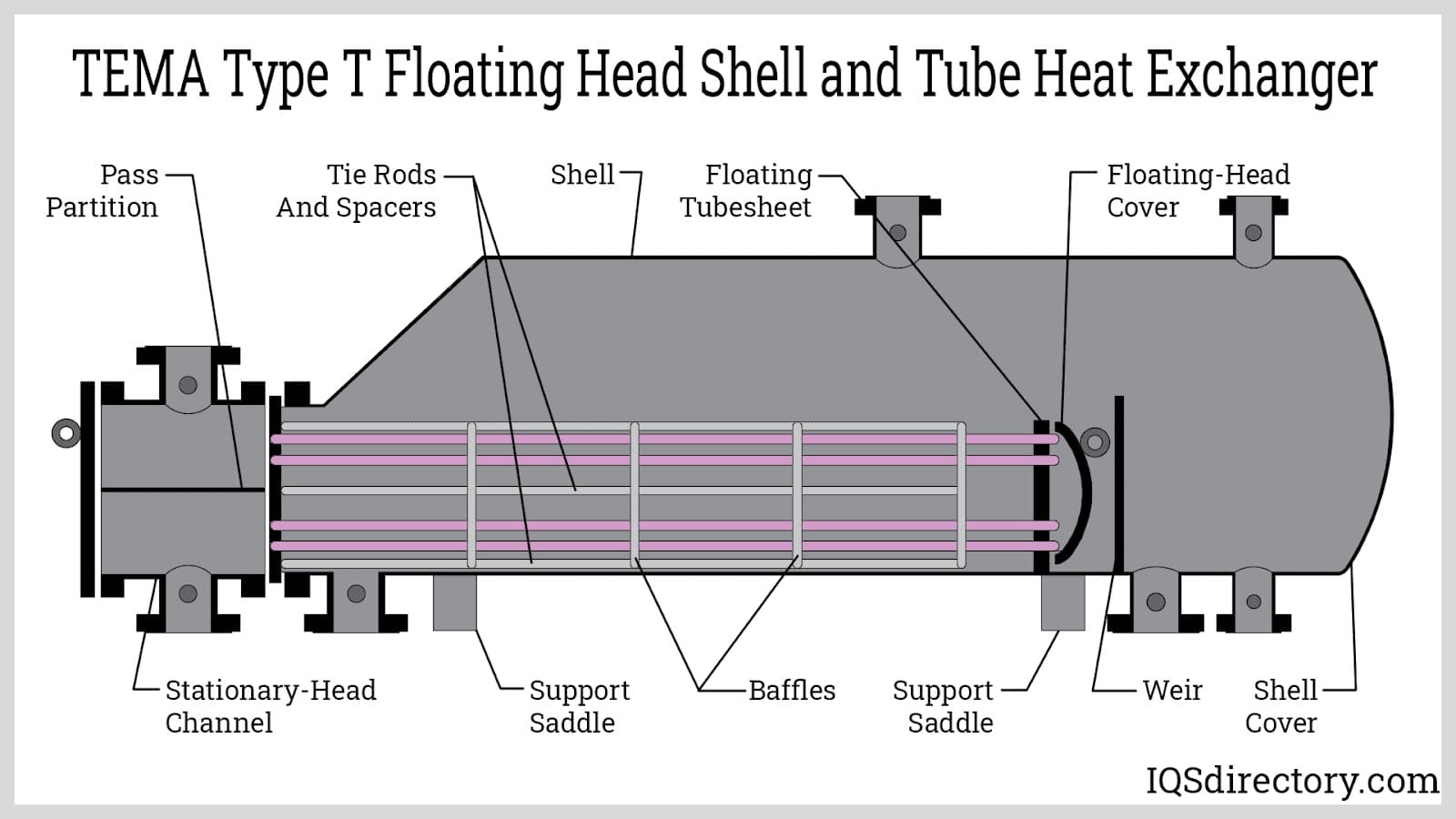

If you want to understand these machines, you have to talk about TEMA. That's the Tubular Exchanger Manufacturers Association. They basically wrote the "bible" for how these things are built. They categorize them by three letters—like AES, BEM, or CFU. The first letter is the front head, the second is the shell type, and the third is the rear head.

A "BEM" is your standard, fixed-tubesheet workhorse. It’s cheap. It works. But there's a catch: you can't easily clean the outside of the tubes. If your shell-side fluid is "dirty" and leaves scale, you're in trouble. That’s why engineers might opt for a "floating head" design. It allows the tube bundle to expand and contract freely without snapping the welds. Thermal expansion is a silent killer in these systems. When one side is 200 degrees hotter than the other, metal grows. If it has nowhere to go, something is going to crack.

How the Fluid Actually Moves (And Why It Matters)

Most people think fluid just goes in one end and out the other. Nope. That would be incredibly inefficient. We use baffles. Think of them as internal walls that force the shell-side fluid to zig-zag across the tubes. This creates turbulence.

Turbulence is the secret sauce.

If the fluid flows smoothly (laminar flow), the layer touching the tube gets cooled, but the stuff in the middle of the stream stays hot. You want that fluid tumbling and mixing. Baffles ensure that the shell-side fluid hits the tubes at a right angle as much as possible, which maximizes the heat transfer coefficient.

The Fouling Nightmare

Let’s talk about the "F" word: Fouling. It’s the buildup of gunk, scale, or algae on the tube surfaces. Honestly, it’s the biggest headache for any plant manager. According to research by Hans Müller-Steinhagen, a leading expert in thermal process engineering, fouling costs industrialized nations about 0.25% of their GDP in lost efficiency and maintenance.

In a shell tube heat exchanger, you have to plan for the "Fouling Factor." You literally build the unit bigger than it needs to be because you know that in six months, it’ll be coated in slime or calcium. If you're running seawater through the tubes to cool a turbine, you're going to get barnacles and salt. You need to be able to run a giant mechanical brush through those tubes. This is why the "tube-side" is usually reserved for the dirtier fluid—it's way easier to clean inside a straight pipe than it is to clean the complex gaps between the pipes.

Materials: More Than Just Steel

You can’t just use carbon steel for everything. If you're handling sulfuric acid or high-chloride water, carbon steel will vanish in weeks.

- Copper-Nickel: Often used in marine environments because it resists biofouling (critters don't like living on it).

- Titanium: The gold standard for corrosion resistance, but it'll cost you a kidney.

- Hastelloy: For when the chemistry is so aggressive it basically wants to eat the building.

- Stainless Steel (304/316): The everyday hero for food, beverage, and moderate chemical use.

Engineering a shell tube heat exchanger involves a constant tug-of-war between cost and longevity. Do you spend $500,000 now on titanium, or $100,000 on carbon steel and replace it every four years? Most CFOs hate the upfront cost, but most maintenance leads hate the downtime.

Misconceptions about Size

"Bigger is better" is a lie in heat transfer. If a shell is too large for the flow rate, the fluid velocity drops. When velocity drops, fouling increases because the gunk has time to settle. You want the fluid moving fast enough to keep the surfaces "self-scouring" but not so fast that it causes erosion or vibration.

💡 You might also like: Requirements to Be an Astronaut: What Most People Get Wrong About NASA’s Selection Process

Acoustic vibration is a real thing. If the fluid hits a certain frequency, it can actually make the tubes hum until they literally fatigue and snap. It sounds like a haunting whistle right before a multi-million dollar disaster.

Real-World Case: The Nuclear Sector

In nuclear power plants, the Steam Generator is basically a massive, ultra-high-spec shell tube heat exchanger. Places like the Palo Verde Generating Station in Arizona use these to transfer heat from the radioactive primary loop to the non-radioactive secondary loop.

There is zero room for error here. These tubes are often made of Inconel 690, a high-nickel alloy that resists stress-corrosion cracking. They are inspected using eddy-current testing, where a probe is sent down the tube to "sense" thinning walls before a leak even happens. It’s the pinnacle of shell-and-tube tech.

Design Mistakes You Should Avoid

If you're in the position of specifying one of these units, don't just give the vendor your inlet and outlet temps. You need to know your pressure drop limits. If you have a pump that can only handle 10 psi of resistance, and your heat exchanger creates 15 psi of "drag," your flow will stall.

Also, watch out for the "Temperature Cross." This happens when the cold fluid outlet temperature is higher than the hot fluid outlet temperature. It's totally possible in multi-pass designs, but it makes the math a lot harder and requires specific shell configurations like an F-shell (two-pass shell).

✨ Don't miss: Why Magic Glasses From Japan Are Actually Just Very Smart Engineering

- Check your Reynolds number: Ensure you are firmly in the turbulent flow regime ($Re > 4000$).

- Account for bypass: Fluid is lazy. It will try to leak around the edges of the baffles instead of going through the tube bundle. Good seals matter.

- Venting and Draining: It sounds basic, but many people forget to put a vent at the high point and a drain at the low point. Trapped air is an insulator; it’ll kill your heat transfer.

Practical Steps for Maintenance

Don't wait for the outlet temperature to drop before you take action. Monitor the pressure gauge. A spike in pressure drop usually means fouling is starting.

If you're seeing a performance dip, try a "CIP" (Clean-In-Place) first. This involves circulating a mild acid or specialized detergent through the system without tearing it apart. It saves days of labor. If that fails, it’s time to pull the head and bring out the hydro-blasters.

Just remember: these machines are the heart of the plant. Treat them with a bit of respect, keep the chemistry in check, and they’ll probably outlast your career.

To get the most out of your thermal system, start by logging your "approach temperature"—the difference between the hot fluid inlet and the cold fluid outlet—daily. When that gap starts to widen, your exchanger is telling you it's getting dirty. Listen to it. Change your filters upstream. It’s much cheaper to replace a $50 filter element than it is to hydro-blast a 20-foot tube bundle.