So, you want to stick it to the Danish toy giant and populate your floor with home-grown plastic bricks? I get it. We’ve all looked at those tiny boxes of plastic and wondered why a handful of ABS costs forty bucks. The dream is simple: buy a spool of filament, hit "print," and suddenly you have an infinite supply of building blocks. But honestly, if you try to print legos with a 3d printer without knowing the physics involved, you’re going to end up with a pile of useless, non-clicking garbage.

It’s about the "clutch power." That's the technical term LEGO designers use for that perfect, satisfying snap that stays together when you pick up a Star Destroyer but comes apart when you want to build something else. Achieving that with a consumer-grade printer is a nightmare of tolerances.

The Brutal Reality of Tolerances

Standard LEGO bricks are manufactured using high-pressure injection molding. We are talking about machines that cost hundreds of thousands of dollars and steel molds polished to a mirror finish. The tolerance—the wiggle room in the dimensions—is less than 0.01mm. To put that in perspective, a human hair is about 0.07mm thick. Your average Creality Ender 3 or even a mid-range Prusa is going to struggle to hit that consistently across a whole bed of parts.

If your brick is 0.1mm too wide, it won't fit. If it's 0.1mm too thin, it falls off.

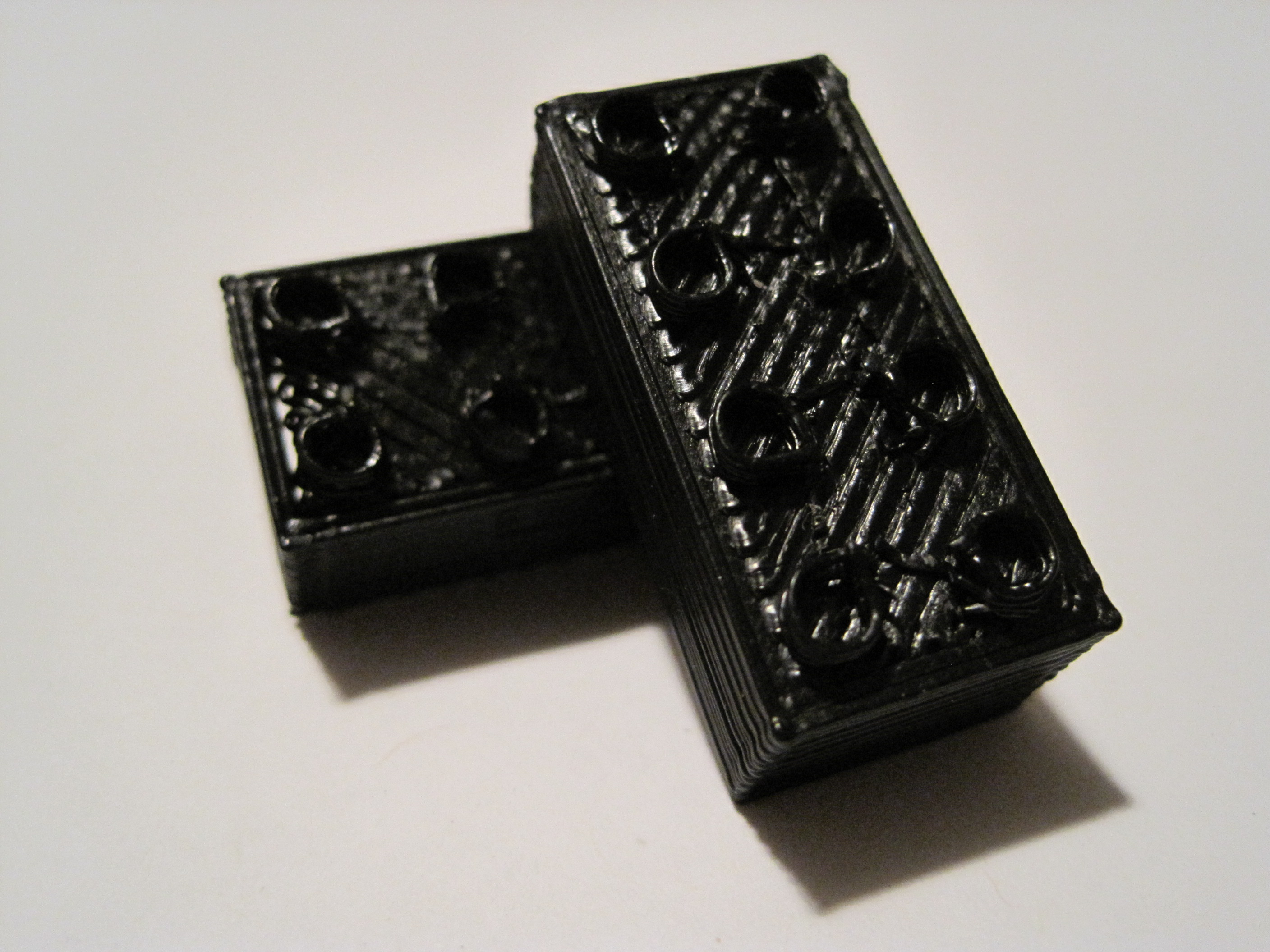

Most people starting out think they can just download an STL from Thingiverse, use default settings, and call it a day. You can't. You'll find that the studs are too fat or the tubes underneath are too tight. 3D printing involves melting plastic, and plastic shrinks as it cools. Different brands of PLA or ABS shrink at different rates. You basically have to become a scientist of your own specific printer.

Choosing Your Weapon: FDM vs. Resin

You've got two main paths here. Most hobbyists own an FDM (Fused Deposition Modeling) printer—the kind that poops out a line of hot plastic. These are great for big, chunky bricks, but the layer lines are your enemy. When you print legos with a 3d printer using FDM, the "rings" on the studs often create friction that makes the bricks nearly impossible to separate once they are joined.

Then there’s SLA (Stereolithography), or resin printing.

👉 See also: Meta AI News Today: Why the Sudden Pivot is Making Everyone Nervous

Resin is a game changer for detail. It uses light to cure liquid goop into solid shapes. The precision is incredible. You can actually get that 0.01mm accuracy. But there’s a catch: resin is brittle. LEGO bricks are famous for being indestructible—you can jump on them, wash them, and they survive for forty years. 3D printed resin bricks tend to shatter or chip. Also, resin is "thirstier" than ABS; it can be tacky if not cured perfectly, which ruins the clutch power.

Honestly? If you want playability, stick to a highly calibrated FDM printer using high-quality PETG or ABS. PLA is too stiff and lacks the "give" needed for a good snap.

Why Materials Actually Matter

LEGO uses acrylonitrile butadiene styrene (ABS). It’s tough, it has a bit of flex, and it holds its shape. When you try to replicate this at home, you’re fighting the "elephant's foot" phenomenon. This is when the first few layers of a print squish down against the heated bed, making the bottom of the brick slightly wider than the top. In the world of bricks, an elephant's foot means your brick won't sit flush on a baseplate.

I’ve seen people try to use TPU (flexible filament). Don't do that. You’ll end up with gummy blocks that feel like those weird off-brand toddler toys.

The Secret of Calibration

- Print a "Calibration Cube" first. If it isn't exactly 20.00mm, your bricks won't work.

- Adjust your "Horizontal Expansion" setting in your slicer (like Cura or PrusaSlicer). This is the secret sauce. A setting of -0.05mm can often be the difference between a brick that fits and one that breaks your fingernails.

- Keep your filament dry. Wet filament bubbles, and bubbles mean inconsistent walls.

Is It Actually Legal?

This is a grey area that gets people fired up in forums. The basic LEGO brick patent expired decades ago. That’s why Mega Bloks and Lepin exist. However, the specific "look" of certain pieces and the LEGO logo itself are protected by trademarks and copyrights.

If you're printing bricks for your kids at home? Nobody cares. If you're trying to sell "3D Printed Custom Bricks" on Etsy, you're walking into a minefield. The LEGO Group is notoriously protective of its intellectual property. They won't come for your printer, but they will send a C&D to your shop if you use their name to sell your plastic.

🔗 Read more: Why the Volta Laboratory and Bureau Changed the Way You Hear the World

The Problem With "Special" Pieces

Standard 2x4 bricks are one thing. But try printing a Technic pin or a transparent windshield. Technic parts require incredible structural integrity because they are under constant tension. A 3D printed pin will almost always shear off along the layer lines the second you put a load on it.

As for transparent parts? Forget it. Unless you have a high-end resin setup and spend hours sanding and clear-coating, your "glass" pieces will look like frosted ice. It's usually cheaper and less soul-crushing to just buy those specific parts from BrickLink.

Real World Results: What to Expect

Let's be real. Your home-printed bricks will never feel exactly like the real thing. They will be louder when you rummage through a bin of them. They will have a different texture. But there is a massive upside: customization.

You can print parts that LEGO refuses to make. Need a 2x9 brick? They don't exist in nature, but you can print one. Want a Gothic-style archway for a MOC (My Own Creation) that fits perfectly into a specific space? That’s where the power of the 3D printer shines. You aren't replacing your collection; you're augmenting it.

Making It Work: Actionable Steps

If you are ready to heat up the nozzle and start your own factory, don't just hit go on a 50-piece plate.

📖 Related: Why You Should Download and Update WhatsApp Right Now (And How to Do It)

First, download a single 2x4 brick. Print it at 100% infill. You need the weight and the internal support to keep the walls from collapsing inward when you press another brick on top. Measure the studs with digital calipers. If they are even 0.1mm off, go back to your slicer and tweak the "XY Size Compensation."

Once you get that one brick to "click" onto a real LEGO baseplate with a satisfying sound, then—and only then—should you start printing in bulk.

Use a 0.2mm nozzle if you have the patience. It's slower, sure. But the detail on the studs will be much crisper, and you'll spend less time with a hobby knife scraping off zits and blobs.

Finally, consider the orientation. Printing a brick "studs up" is the easiest, but printing it on its side can sometimes result in stronger studs because the layer lines run vertically through the connector. It's a trade-off.

Building a custom empire takes time. Your printer is a tool, not a magic wand. Treat it like a precision instrument, and you'll eventually have a bucket of bricks that actually work.

Next Steps for Success:

- Calibrate your E-steps to ensure your printer is extruding the exact amount of plastic required; over-extrusion is the number one killer of clutch power.

- Invest in a PEI sheet for your print bed to minimize "elephant's foot" and ensure the bottom of your bricks are perfectly flat.

- Test with PETG if you find PLA is too brittle for long-term play; it offers a better balance of flexibility and strength that mimics the original ABS feel without the warping issues of printing raw ABS.