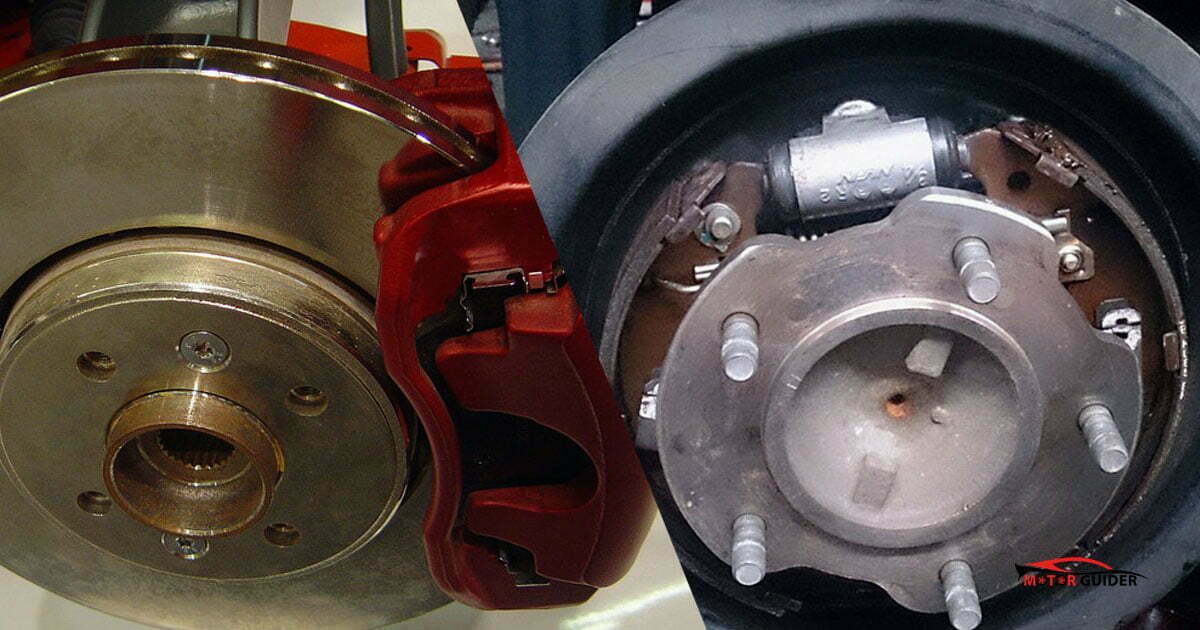

You’re staring at those rusty, circular iron weights behind your rear wheels and wondering if they’re actually doing anything. They are. Sorta. But if you’ve ever felt that terrifying "brake fade" while descending a steep hill or trying to stop a heavy classic car in modern traffic, you know exactly why people ask: how do you change drum brakes to disc brakes without ruining the car?

It’s about heat. Drums are basically ovens. They trap heat inside the assembly, and once things get too hot, your stopping power evaporates. Discs? They’re open to the air. They shed heat like a runner sheds a jacket. If you’re tired of the "pedal-to-the-floor" prayer, a conversion is the single most impactful mechanical change you can make to an older vehicle.

The Reality of the Swap: It’s Not Just Bolting Things On

Most people think you just swap a drum for a rotor and call it a day. Honestly, that’s how people end up in ditches. When you ask how do you change drum brakes to disc brakes, you have to think about the "bias." Drum brakes require a lot of residual pressure to keep the shoes close to the drum. Disc brakes don't. If you leave your old residual pressure valves in place, your new disc brakes will drag, overheat, and wear out in a week.

You’re going to need a few specific things. A master cylinder designed for four-wheel discs is usually non-negotiable. Why? Because disc calipers require a larger volume of fluid to move the pistons than drum wheel cylinders do. If you keep your old master cylinder, the pedal might feel like mush, and you'll find yourself pumping it just to get the pads to touch the rotor.

The Component List Nobody Mentions

Everyone talks about the shiny rotors. Nobody talks about the parking brake cables. Most drum parking brakes use a completely different pull-length than disc setups. If you’re doing a swap on an old Chevelle or a Mustang, you'll likely need a custom-length cable or an adjustable connector.

Then there's the proportioning valve. This is the "brain" of your brake system. It decides how much pressure goes to the front versus the rear. Since discs are much more efficient at grabbing, you need a valve that lets you dial back the rear pressure. Otherwise, the second you tap the brakes on a wet road, your rear wheels will lock up and send you spinning.

👉 See also: LG UltraGear OLED 27GX700A: The 480Hz Speed King That Actually Makes Sense

Tearing Down the Old Iron

Start by getting that car up on jack stands. High. You need room to move. Pull the wheels and prepare for a mess. Drum brakes are notorious for collecting decades of asbestos-laced dust. Don't blow it out with a compressor. Use a dedicated brake cleaner spray to soak everything down so the dust stays liquid and drips into a pan.

Once the drum is off—which might require a literal sledgehammer if it's rusted to the hub—you’ll see the "clockwork" of springs and shoes. You don't need to be delicate here unless you plan on selling the old parts on eBay. Snip the hold-down springs, pop the shoes out, and disconnect the hydraulic line.

Pro Tip: Keep a flare nut wrench handy. Using a standard open-end wrench on old brake lines is the fastest way to round off a fitting and turn a two-hour job into a two-day nightmare involving new hard lines.

Modifying the Spindle or Flange

On many older cars, the bracket that holds the new caliper won't just slide on. You might have to grind down a small portion of the axle flange or the spindle. It feels wrong to take a grinder to your car’s suspension, but it’s a standard part of the process for many aftermarket kits from companies like Wilwood or SSBC.

Check your clearances. Twice. Then check them again. The rotor needs to sit perfectly flush against the hub. If there’s even a millimeter of "runout" (wobble), you’ll feel a pulsing sensation in the brake pedal that will drive you absolutely insane at stoplights.

✨ Don't miss: How to Remove Yourself From Group Text Messages Without Looking Like a Jerk

Installing the New Hardware

This is the satisfying part. You slide that brand-new, vented rotor onto the studs. It looks clean. It looks fast. But before you bolt the caliper on, make sure the bleeder screw is pointing up.

It sounds stupid, but it’s the most common mistake in the book. If the bleeder screw is at the bottom of the caliper, air will stay trapped at the top. You will bleed those brakes for three days and never get a firm pedal. Up is out. Always.

Plumbing and Fluid

When figuring out how do you change drum brakes to disc brakes, the plumbing is where the "pros" separate themselves from the "mudders." You’ll need new flexible rubber (or braided stainless steel) lines to connect the caliper to the hard lines on the frame or axle.

- Don't reuse old copper washers. They’re "one-and-done" crush gaskets.

- Route the lines so they don't kink when the suspension moves up and down.

- Avoid zip ties for anything structural; use proper line clips.

The Bleeding Process (The Final Boss)

You’ve got the parts on. The car looks great. Now you have to get the air out. Start at the wheel furthest from the master cylinder (usually the passenger rear). Work your way closer.

If you’re doing this alone, get a vacuum bleeder. If you have a friend, use the "Pump, Pump, Hold" method. Don't let the master cylinder run dry during this process, or you’ll have to start over from the very beginning. It’s tedious. It’s boring. But air in the lines is literally the difference between stopping and hitting a tree.

🔗 Read more: How to Make Your Own iPhone Emoji Without Losing Your Mind

Bench Bleeding the Master Cylinder

If you replaced the master cylinder (and you probably should), you can't just bolt it on and start bleeding the wheels. You have to "bench bleed" it first. This involves looping short lines from the exit ports back into the reservoir and pumping the piston until no more bubbles appear. If you skip this, you’ll spend hours trying to push a giant air pocket through twenty feet of brake line. It won't work. Trust me.

Critical Safety Checks Before the Test Drive

Before you drop the car, have someone mash the brake pedal as hard as they can while you look at every single fitting. You’re looking for "weeping." If a drop of fluid appears at a junction, it’s not tight enough. Under panic-braking pressure, that tiny weep will become a geyser.

Check the wheel clearance. Sometimes, the new calipers are chunkier than the old drums. You might find that your cool vintage wheels now hit the caliper. If that happens, you’ll need spacers or—worst case—different wheels.

Actionable Steps for Your Conversion

If you're ready to make the jump, don't just buy the cheapest kit on a random auction site. Your life depends on these parts.

- Identify your rear-end housing. Is it a Ford 9-inch? A GM 10-bolt? The bolt pattern on the axle flange determines which bracket you need.

- Order a complete kit. For beginners, "complete" means rotors, calipers, pads, brackets, hoses, and a proportioning valve. Sourcing these piecemeal is a headache you don't want.

- Measure your wheel diameter. Most disc conversions require at least 15-inch wheels. If you're running 14-inch "survivor" wheels, your options are very limited.

- Buy two bottles of high-quality DOT 3 or DOT 4 fluid. You will use more than you think during the bleeding process.

- Invest in a flare nut wrench set. Seriously. It saves your hardware from being stripped.

Changing from drums to discs isn't just a "mod." It’s a fundamental safety upgrade that changes the entire character of how a vehicle drives. You'll go from planning your stops three blocks in advance to having modern, crisp deceleration. Just take your time, keep the grease off the pads, and ensure your bleeder screws are facing the sky.