Walk into any industrial park in the Midwest and you'll see a lot of gray. Gray siding, gray trucks, gray machines. But in a specific corner of Washington County, things are a lot more colorful. Honestly, if you’ve ever looked at a piece of heavy machinery or a high-end metal fixture and wondered how the paint stays so perfect despite being beaten up by the elements, there is a decent chance Hartford Finishing in Hartford Wisconsin had a hand in it. They aren't just "painters." That's like calling a surgeon a "cutter."

They are specialists.

Industrial coating is one of those invisible industries. It’s essential, but nobody talks about it until their equipment starts rusting or the finish on a product looks like it was applied by a toddler with a spray can. Since 1986, this company has been sitting in Hartford, growing from a small-scale operation into one of the largest contract powder coaters in the entire United States. It's a massive footprint. We are talking about a 250,000-square-foot facility. That is basically four and a half football fields of ovens, conveyor lines, and chemical wash stations.

It's big. Really big.

The Reality of Powder Coating at Scale

Most people think powder coating is just for car rims. You take a part, you spray some plastic dust on it, you bake it, and boom—you’re done. But when you are dealing with the volume that Hartford Finishing in Hartford Wisconsin handles, the physics gets complicated. They aren't just doing one-offs for a local hobbyist. They are integrated into the supply chains of major Original Equipment Manufacturers (OEMs).

Think about the sheer logistics.

You have to manage chemistry. You have to manage heat. You have to manage a conveyor system that never seems to stop moving. If the pretreatment wash is off by even a fraction of a percentage in its pH balance, the entire batch of parts is ruined. That’s why they’ve invested so heavily in their laboratory and testing setups. They test for salt spray resistance, impact, and even how well the coating bends without cracking. It’s science disguised as blue-collar work.

💡 You might also like: Mississippi Taxpayer Access Point: How to Use TAP Without the Headache

The facility runs multiple lines. Some are dedicated to massive parts—huge weldments that look like they belong on a bridge. Others move lightning-fast for smaller components. This versatility is probably why they survived the various economic dips that have crushed other manufacturers in the Great Lakes region. They didn't put all their eggs in one basket. They serve agriculture, construction, lawn and garden, and even the medical field.

Why the Location Actually Matters

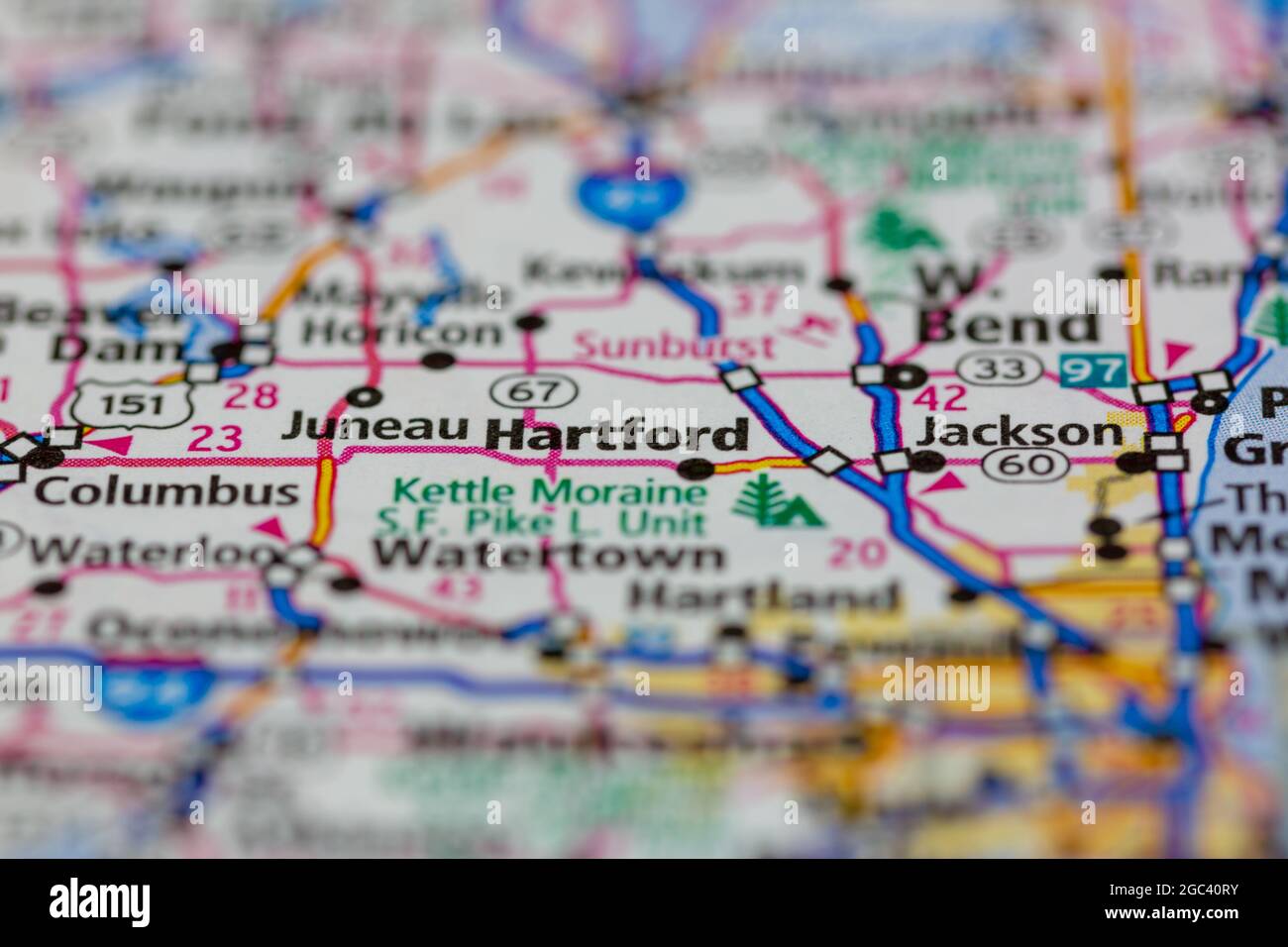

Hartford isn't Milwaukee. It isn't Chicago. But for a business like this, that is a massive advantage. Being in Hartford, Wisconsin, places the company right in the "Machine Shop of the World." Within a two-hour drive, you have some of the most intense manufacturing density on the planet.

- Logistics costs are lower because they are central to the customer base.

- The labor pool in Washington County is legendary for its work ethic.

- They have room to expand that you just don't find in urban centers.

It's about the grit. People in this part of Wisconsin know how to work with their hands. They understand that "close enough" isn't a phrase used in ISO 9001 certified facilities. When you're coating parts for a tractor that is going to live outside in North Dakota for thirty years, the finish has to be bulletproof. Literally.

More Than Just Powder: Liquid and Assembly

A lot of folks get confused and think powder is the only game in town. It's not. Hartford Finishing in Hartford Wisconsin also runs liquid coating lines. Why? Because some parts can't take the heat. You can't stick a part with rubber seals or delicate electronics into a 400-degree oven without ending up with a melted puddle of regret. Liquid coating allows them to hit those sensitive specs while still providing that industrial-grade protection.

Then there is the "Value-Added" side of things. This is where the business gets smart.

Instead of just coating a part and shipping it back, they started doing assembly. They'll take the metal, coat it, put the stickers on, install the plastic handles, and package it for the final consumer. It saves the customer a trip. It's basically a one-stop shop. Honestly, in a world where shipping costs are skyrocketing, being able to cut out a leg of the journey is a massive selling point for any supply chain manager.

📖 Related: 60 Pounds to USD: Why the Rate You See Isn't Always the Rate You Get

The Environmental Elephant in the Room

Let's be real for a second. Industrial painting used to be a toxic nightmare. Old-school wet paint involved a lot of Volatile Organic Compounds (VOCs) that were terrible for the lungs and the planet. Powder coating changed that. It’s a "dry" process. There are no solvents. Any powder that doesn't stick to the part can often be reclaimed and reused.

Hartford Finishing has leaned into this. They aren't just doing it because they're "green"—though that's a nice perk—they're doing it because it's efficient. Waste is expensive. By using automated spray booths and reclaim systems, they keep the overhead down and the air clean. It’s one of those rare moments where the bottom line and environmental stewardship actually walk hand-in-hand.

Facing the Challenges of 2026

It isn't all sunshine and rainbows. Manufacturing in the mid-2020s is tough. Labor shortages are real. Automation is no longer a luxury; it’s a requirement. If you walk through their plant today, you’ll see robots doing the heavy lifting. Not because they want to replace people, but because they can't find enough people to do the repetitive, grueling tasks of moving heavy metal all day.

Then you have the energy costs. Running massive curing ovens takes a staggering amount of natural gas and electricity. Staying competitive means they have to be masters of thermal efficiency. They have to ensure those ovens aren't leaking heat and that the line speeds are optimized to the second.

- Investment in robotic spray arms.

- Sophisticated ERP systems to track every nut and bolt.

- Cross-training staff to handle multiple roles.

- Constant re-certification of quality standards.

It's a high-stakes game. One bad batch of chemicals from a supplier can shut down a line for days. One power outage can ruin tens of thousands of dollars in product currently sitting in the ovens. You need nerves of steel to run a shop this big.

What Most People Miss About the Business

The most interesting thing about Hartford Finishing in Hartford Wisconsin isn't the machines. It's the diversity of the work. One day they are coating components for a military vehicle, and the next, they are finishing the frames for high-end office furniture. That variety requires a level of agility that most small shops simply can't match.

👉 See also: Manufacturing Companies CFO Challenges: Why the Old Playbook is Failing

They've also become a bit of a local titan. In a town like Hartford, a company with hundreds of employees is more than just a business. It’s a pillar. They sponsor local events, they provide a career path for kids coming out of the local tech colleges, and they keep the local "support" economy—the tool and die shops, the truckers, the lunch spots—humming along.

Actionable Insights for Manufacturers and Partners

If you are looking at Hartford Finishing from a business perspective, there are a few things to keep in mind. First, don't just show up with a part and expect a quote in five minutes. Industrial coating at this level requires a deep dive into the "end-use" of the product.

- Specify the Environment: Tell them if the part will be in salt air, high heat, or constant UV sunlight.

- Think About Masking: If there are threads or holes that can't have paint in them, be clear. Precision masking is an art form.

- Batch Your Work: Shipping ten parts a week is a nightmare. Shipping five hundred parts once a month is a dream. Logistics matter.

- Consult Early: Talk to their engineers before you finalize your part design. Sometimes a small tweak in a weldment can make it much easier (and cheaper) to coat.

The future of American manufacturing depends on companies that can scale without losing their souls. Hartford Finishing seems to have found that balance. They have the "big company" capabilities but they still feel like a Wisconsin shop. They still care if the finish is smooth. They still care if the customer is happy.

Steps to Optimize Your Supply Chain with Industrial Coating

If you’re a product manager or an engineer, you need to treat your finisher as a partner, not a vendor.

Review your current failure rates. If you’re seeing rust or chipping within the first year of your product's life, your coating process is likely the culprit. Reach out to the team in Hartford and ask for a line audit. They can often spot design flaws—like "water traps" in your metal parts—that cause premature corrosion.

Next, look at your "Total Cost of Ownership." It might be cheaper to get a part painted at a tiny shop down the street, but if they don't have the quality controls or the assembly capabilities of a place like Hartford Finishing, you'll end up paying more in the long run through shipping and rework.

Finally, keep an eye on the tech. Coatings are changing. There are now "smart" coatings that can resist bacteria or even heal themselves from small scratches. Staying in touch with a high-volume leader like this ensures you aren't using 1990s technology for a 2026 product. Metal is only as good as the skin you put on it.