Building a raised bed seems easy enough until the soil gets wet. You buy some cedar or pressure-treated 4x4s, screw them together at the ends, and call it a day. Then winter hits. The ground freezes, the soil expands, and suddenly those screws are pulling through the soft wood grain. Honestly, it's a mess. Most people think they can just "toe-nail" screws into the ends of boards, but wood is a living, breathing thing that moves. Without garden raised bed corner brackets, your beautiful vegetable patch is basically a ticking time bomb of structural failure.

I’ve seen beds made by DIYers that look great for exactly one season. By year three, the corners are gaping open by two inches. Why? Because the lateral pressure of several hundred pounds of damp soil is no joke. It pushes outward constantly. A simple screw into the end grain of a board has almost no holding power. It's like trying to nail two sponges together. You need steel. Specifically, you need brackets that wrap around the outside or reinforce the inside with a mechanical grip that doesn't rely on the wood's integrity alone.

The Physics of Soil Pressure and Why Corners Fail

Soil is heavy. A single cubic foot of moist garden soil can weigh anywhere from 75 to 100 pounds. If you have a 4x8 bed that is 12 inches deep, you're looking at nearly 3,000 pounds of material. All that weight wants to go down and out. The corners are the weakest point because that's where the structural continuity breaks.

When you use garden raised bed corner brackets, you are essentially creating a structural "cage" for the soil. High-quality brackets, like the ones produced by companies like Gardener's Supply Company or various heavy-duty options on Etsy, are typically made of powder-coated steel or aluminum. They provide a rigid surface for the wood to butt against. Instead of the screw taking the force, the metal plate takes it. It's a massive difference in longevity.

Think about the "bowing" effect. Have you ever noticed a long raised bed that looks like it’s bulging in the middle? That’s the same pressure that destroys corners. While center bracing helps with the belly of the bed, the corners are the anchors. If the anchor fails, the whole side wall can blow out, spilling your expensive organic compost and ruining your root systems. It happens fast. One big rainstorm can be the tipping point.

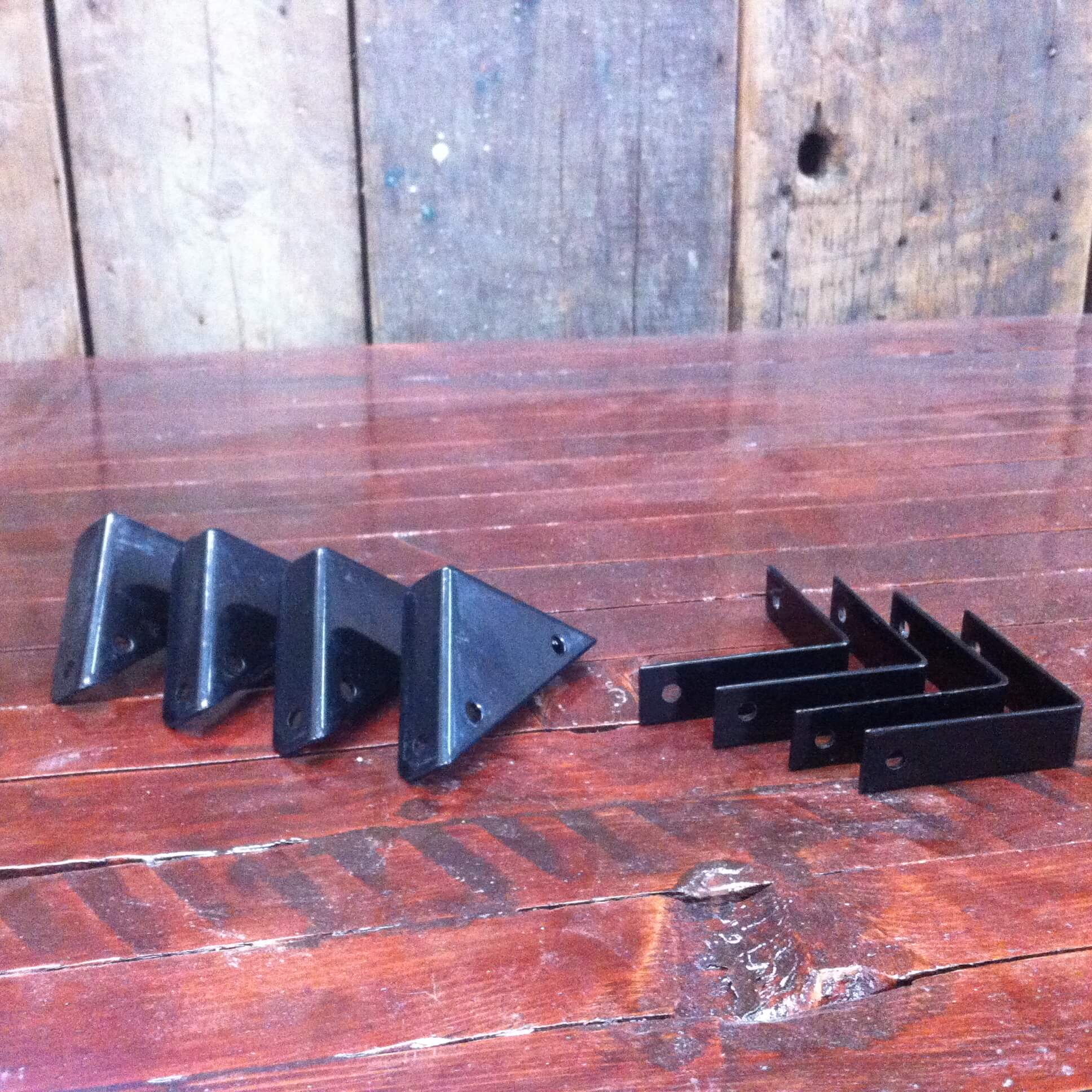

Material Choices: Powder-Coated Steel vs. Aluminum vs. DIY

You’ve got options. Some people go the cheap route and buy galvanized "L" brackets from a big-box hardware store. Don't do that. Those thin little braces are designed for shelving or light framing, not for holding back half a ton of mud. They will bend. Or worse, the zinc coating will flake off, and they’ll rust through in two seasons.

- Powder-Coated Steel: This is the gold standard. It’s heavy. It’s stiff. The coating prevents the steel from rusting while also looking sharp against the wood. Brand names like Gronomics use these to great effect.

- Aluminum: It won't rust, ever. That's the pro. The con? It’s softer than steel. If you’re building a very tall bed—say, 24 inches or higher—thick gauge steel is usually a safer bet than aluminum.

- Raw Steel (Cor-Ten): Some gardeners love the rusted look. Cor-Ten steel forms a protective layer of rust that actually prevents further corrosion. It looks incredible with weathered cedar. It's very "architectural digest" but can be pricey.

I once talked to a guy who used plastic brackets. Just... no. UV rays from the sun will make that plastic brittle within two years. You'll go to pull a weed, bump the corner with your foot, and the whole thing will crack. If you're spending the money on cedar or redwood—which is currently through the roof in terms of price—don't cheap out on the hardware. It's like putting budget tires on a Ferrari.

👉 See also: Sport watch water resist explained: why 50 meters doesn't mean you can dive

What Most People Get Wrong About Installation

It’s not just about slapping a bracket on. You need to consider the height of your wood. Most garden raised bed corner brackets come in specific heights, usually 6, 8, 10, or 12 inches. If your wood is 12 inches tall, don't use a 6-inch bracket. You want the bracket to cover as much of the vertical seam as possible to prevent the boards from twisting.

Wood twists. It's what it does. As it dries in the sun and gets soaked by the hose, it cups and bows. A tall bracket acts as a spline, keeping those boards stacked perfectly flush.

Another tip: use structural screws. Those skinny gold wood screws are brittle. They can literally snap under the shear force of shifting wood. Use something like a GRK structural screw or a TimberLOK if you’re using thick timbers. They have a higher shear strength and won't pop their heads off when the bed settles.

The Aesthetic Factor

Let's be real—we want the garden to look good. Raw wood corners often look "farm-style" or a bit rugged. That’s fine for a back-forty vegetable patch. But if your raised beds are in the front yard or part of a formal patio design, garden raised bed corner brackets give a finished, intentional look.

You can find brackets with decorative cutouts—leaves, birds, or geometric patterns. It turns a utility item into a design feature. It also allows you to use thinner boards. If you have beefy corner brackets, you can sometimes get away with 1-inch thick cedar boards instead of 2-inch "two-bys," because the bracket is doing the heavy lifting of keeping the shape. This can actually save you money on lumber, which might even pay for the brackets themselves.

Height Matters More Than You Think

If you're building a "tall" bed—anything over 18 inches—the pressure at the bottom is significantly higher than at the top. This is basic fluid dynamics applied to soil. For these deep beds, I always recommend brackets that have a "staking" feature. Some brackets have a long metal leg that extends 6 to 12 inches into the ground. This anchors the bed so it can't "creep" or slide down a slope over time. It’s a lifesaver if your yard isn't perfectly level.

✨ Don't miss: Pink White Nail Studio Secrets and Why Your Manicure Isn't Lasting

A Note on Different Wood Types and Corrosion

If you are using ACQ pressure-treated lumber (the modern green stuff), you have to be careful. The chemicals used to prevent rot in that wood are highly corrosive to copper and standard steel. If you put a cheap, non-rated bracket on pressure-treated wood, the wood will literally eat the metal. You’ll see streaks of rust within months.

For pressure-treated wood, you must use stainless steel or hot-dipped galvanized brackets. Powder coating is usually fine as long as the coating isn't scratched during installation. If you scratch the paint, the chemical reaction starts. Honestly, this is why most "serious" gardeners stick to cedar or hemlock. It’s naturally rot-resistant and doesn't play chemistry sets with your hardware.

Dealing with "The Gap"

No matter how well you cut your wood, there's often a little gap at the corner. It's annoying. Water gets in there, sits, and starts the rot process from the inside out. Brackets that wrap around the outside of the corner (external brackets) are great because they hide these imperfections. You don't have to be a master carpenter with a miter saw. You can do simple butt joints, and the bracket covers the ugly end-grain. It makes the project much faster.

Real World Cost Analysis

Is it worth the extra $40 to $100 per bed?

Let's look at the math. A 4x8 cedar bed using 2x12 boards costs about $150 in lumber alone right now. If that bed lasts 5 years because the corners rot or blow out, you're paying $30 per year. If you spend $60 on high-quality garden raised bed corner brackets and the bed lasts 12 years because the joints stayed tight and the wood didn't warp or split at the ends, you're paying $17.50 per year.

It's a classic case of "buy once, cry once."

🔗 Read more: Hairstyles for women over 50 with round faces: What your stylist isn't telling you

Step-by-Step Practical Application

- Level the Ground: Do not skip this. If your ground is wonky, your corners will never be square, and your brackets will be under unnecessary tension from day one. Use a shovel, get it flat.

- Pre-Drill Your Holes: Even if the screws say "self-tapping," drill a pilot hole. Cedar is notorious for splitting at the ends. A pilot hole ensures the screw grips the fibers rather than wedging them apart.

- Check for Square: Before you tighten everything down, measure your diagonals. If the distance from the back-left corner to the front-right corner is the same as the back-right to the front-left, you're golden.

- Seal the End Grain: Before you put the bracket on, hit the ends of the boards with a bit of wood sealer or even just some outdoor-rated wood glue. This stops moisture from wicking into the board.

- Mount the Brackets: Slide them on. If you're using internal brackets, make sure they are flush with the top. If you're using external "sleeve" style brackets, make sure the wood is seated all the way into the corner.

Beyond the Corners: The Middle Support

While we're talking about structural integrity, I have to mention that for any bed longer than 6 feet, even the best corner brackets won't stop the long sides from bowing out. You should use a matching "straight" bracket or a simple piece of galvanized aircraft cable across the center of the bed, halfway up the sidewall. Attach it to the side boards. This works in tandem with your corner brackets to keep the bed perfectly rectangular for a decade or more.

There is a huge community of "square foot gardeners" who swear by these systems. They’ve tested everything from cheap plastic stakes to heavy-duty angle iron. The consensus is almost always the same: the corner is the soul of the bed. If the soul is weak, the garden fails.

Specific Recommendations Based on Use Case

If you are building a small herb garden on a patio, you can get away with the smaller, decorative 6-inch brackets. They look "cute" and provide enough support for the low soil volume.

However, if you are doing a "Hugelkultur" style bed (where you bury logs and branches under the soil), you absolutely must use the heaviest duty 12-gauge steel brackets you can find. As those logs break down over the years, the soil will shift and settle in unpredictable ways. The torque on those corners will be immense. I’ve seen 4x4 posts snapped by the settling force of a large-scale raised bed. Don't underestimate the power of gravity and decomposition.

The Maintenance Myth

People think steel brackets are "set it and forget it." Mostly, they are. But once a year, usually in early spring before you plant, take a wrench or screwdriver and just check the tightness. Wood shrinks when it gets cold and dry in the winter. Those screws might need a quarter-turn to stay snug. It takes five minutes and adds years to the life of the structure.

If you see a chip in the powder coating, hit it with a tiny dab of outdoor spray paint or even nail polish. Preventing that first spot of rust is the key to making the brackets last 20 years instead of seven.

Actionable Next Steps

- Measure your lumber thickness: Before ordering brackets, ensure you know if you're using "1-inch" (actual 0.75") or "2-inch" (actual 1.5") lumber. Most brackets are designed for specific thicknesses.

- Audit your soil height: Calculate your soil volume. If you're going over 12 inches deep, prioritize brackets that include a ground stake or "anchor" leg for lateral stability.

- Choose your aesthetic: Decide if you want the brackets to be "hidden" (internal) for a clean wood look or "exposed" (external) for a modern, industrial, or decorative feel.

- Buy structural fasteners: Abandon standard drywall or deck screws. Purchase 1/4-inch diameter structural lag screws to ensure the hardware never shears off under pressure.