Walk into any industrial park in America and you’ll see them. Those faded, dented, or—even worse—hand-written cardboard "Shipping and Receiving" signs taped to a bay door. It looks temporary. It feels cheap. But here’s the thing: that little piece of plastic or metal is actually the first handshake your business gives to the outside world. If a driver spends twenty minutes circling your lot because they can't find the right door, you aren't just losing their respect. You're losing money. Real money.

Logistics is a game of minutes. Honestly, it’s a game of seconds.

A well-placed shipping and receiving sign isn't just about being polite to the guy driving the Peterbilt. It's about site flow. It’s about safety. Most importantly, it’s about making sure your internal operations don't grind to a halt because a delivery ended up at the front office instead of the loading dock. I’ve seen million-dollar facilities fail at this basic task, and it's frankly kind of embarrassing when you consider how easy it is to fix.

The Chaos of the Unmarked Dock

Think about the driver’s perspective. They’ve been on the road for eleven hours. They’re dealing with ELD (Electronic Logging Device) timers that are ticking down to a mandatory rest period. They pull into a complex with six different buildings and zero clear direction.

When you don't have a clear shipping and receiving sign, you create a ripple effect. The driver gets frustrated and blocks a fire lane. They walk into the main lobby, tracking grease across the carpet, just to ask where the dock is. Your receptionist, who has enough to do, now has to play traffic controller.

This isn't just a minor annoyance. According to data from the Occupational Safety and Health Administration (OSHA), struck-by hazards are a leading cause of warehouse injuries. Confused drivers in heavy machinery are dangerous. If a driver is squinting to read a tiny sign while backing up a 53-foot trailer, they aren’t looking at the guy walking across the lot with a clipboard. Clear signage literally saves lives by reducing "wandering" time.

Materials That Actually Last (And Why Most Fail)

Don't buy the cheap stuff. Seriously.

Most people hop on a generic office supply site and buy a thin plastic sign. Within six months, the UV rays from the sun have bleached it white. Or, even better, the first winter storm cracks it like an eggshell. If you’re mounting a shipping and receiving sign outdoors, you need .080 aluminum. It’s the industry standard for a reason. It doesn't rust. It doesn't warp.

You also need to think about reflectivity. 3M High Intensity Prismatic (HIP) sheeting is what you see on stop signs. It’s bright. It catches headlights. If your facility runs 24/7 or has early morning pickups in the dark, non-reflective signs are basically invisible. You might as well not even have them.

Placement Strategy: The Science of Where to Hang It

A sign is useless if it’s blocked by a parked van or hidden behind a tree branch. You’ve got to think about the "Sight Triangle."

Drivers need to see the sign from the entrance of the property, not just when they are ten feet away from the door. This often means you need a hierarchy of signage.

- The Entrance Sign: A large directional arrow at the street level.

- The Intermediate Sign: Mid-lot directions if the path isn't a straight shot.

- The Point-of-Arrival Sign: The actual "Shipping and Receiving" marker right above the bay or the man-door.

Keep it high. At least seven to ten feet off the ground. This keeps it above the roofline of most delivery vans and prevents it from being obscured by snowbanks in the winter or overgrown weeds in the summer.

✨ Don't miss: Hutchens Mortuary & Cremation Center Florissant MO: What Most People Get Wrong

And for the love of everything efficient, make sure the text is big enough. A person with 20/20 vision can read about 50 feet of distance for every inch of letter height. If you want a driver to see your sign from 200 feet away, those letters need to be at least four inches tall. Anything smaller is just decorative.

The Language of Logistics

"Shipping and Receiving" is the standard. But is it accurate for your workflow?

Some facilities separate these functions entirely. If Shipping is at Dock A and Receiving is at Dock B, putting one sign in the middle is a recipe for disaster. I’ve seen warehouses where "Receiving" is actually around the back of the building, but the only sign visible from the road says "Shipping & Receiving" with an arrow pointing toward the front. Drivers follow the arrow, get stuck in a tight turn, and then have to back out into traffic.

Be specific. If you have a "Driver Check-In" window, label it. If you have a "No Idling" policy, put that on the same post. Clarity is kindness in the world of freight.

Compliance and the "Hidden" Rules

Did you know that some local municipalities have strict codes about how many signs you can have and how large they can be? It's true. Before you bolt a massive 48-inch sign to your exterior wall, you might want to check your local zoning laws.

Beyond city code, there's the ADA (Americans with Disabilities Act). While a shipping and receiving sign on an exterior dock door might not always fall under strict ADA tactile requirements (like braille), any sign marking a permanent room or space inside the building does. If your receiving office is inside, that sign needs to have raised characters and braille, mounted at the correct height (usually 48 to 60 inches from the floor).

Failing an inspection because of a $40 sign is a frustrating way to lose a day.

Why Color Matters (More Than You Think)

Most people default to white text on a blue background. It’s standard. It’s "business-y."

But if your building is blue, that sign is going to disappear. Contrast is your best friend. Safety Yellow with Black text is the highest-contrast combo available. It screams "Instructional." It demands attention. If you want to keep a cleaner aesthetic, White on Forest Green or Black on Silver works, but you sacrifice a bit of that immediate "look at me" factor that helps drivers navigate quickly.

The Psychological Impact on Your Team

This is the part people usually ignore.

Your warehouse staff is under a lot of pressure. When they have to constantly stop what they are doing to redirect a lost driver, it breaks their flow. It ruins their "pick rate." It makes them grumpy.

Installing a professional shipping and receiving sign sends a message to your employees: We have our act together. It shows that management cares about the details. It reduces the number of "random people" wandering onto the warehouse floor, which is a massive security and insurance risk.

Think about it. If anyone can just walk in because they didn't see a sign, you've lost control of your perimeter. That’s how freight grows legs and walks away.

🔗 Read more: GDP Growth Rate US: What Most People Get Wrong About the 2026 Economy

Modern Tech and Signage Integration

We’re moving into an era of "Smart Signage," but don't let that distract you from the basics. Even if you use a digital check-in system or a mobile app for your carriers, the physical sign remains the "fail-safe."

If the Wi-Fi goes down or the driver’s phone dies, they still need to know where to go.

I’ve seen some clever uses of QR codes on a shipping and receiving sign. A driver pulls up, scans the code without even leaving their cab, and gets a text when their bay is ready. It’s brilliant. But that QR code is useless if it’s printed on a piece of paper that’s currently fluttering away in the wind. It needs to be part of a permanent, high-quality sign installation.

Actionable Steps for Your Facility

Don't just read this and go back to your spreadsheets. Take ten minutes and go outside. Drive to the street entrance of your facility.

Actually try to find your loading dock as if you’ve never been there before.

Can you see the shipping and receiving sign from the turn-in point? Is the text legible? Is the sign hanging straight, or is it dangling by a single rusty screw? If you struggle to find it for even three seconds, you have a problem.

- Audit the entrance: Stand where a driver stands. If the view is blocked by a dumpster or a tree, move the sign or trim the tree.

- Check the mounting: Use stainless steel hardware. Zinc-plated stuff will streak your building with rust within a year.

- Standardize the look: If you have multiple signs, make sure they use the same font and color scheme. It creates a "visual trail" for the driver to follow.

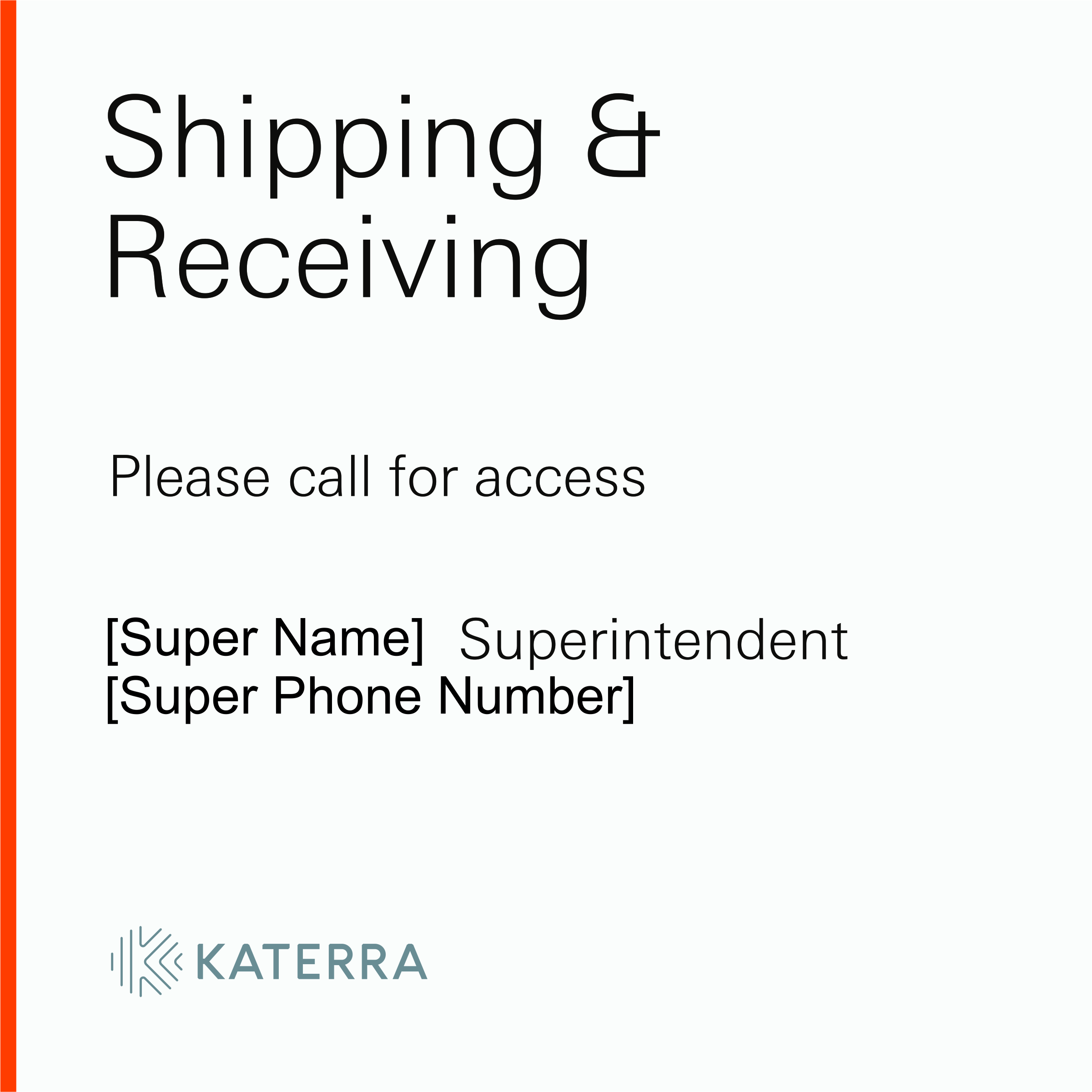

- Add a phone number: Sometimes, despite your best efforts, a driver gets stuck. A small line of text at the bottom of the sign with a "Dock Office" phone number can prevent a lot of honking and shouting.

- Clean them: Once a year, hit your signs with some soapy water. Road grime and exhaust soot build up, cutting the reflectivity and making the sign look dingy.

A warehouse is a machine. A shipping and receiving sign is just one small gear in that machine, but if it's missing or broken, the whole thing runs a lot louder and a lot slower. Fix your signs. Your drivers, your staff, and your bottom line will thank you.