Hardware is hard. You've probably heard that a thousand times if you're hanging around the MaRS Discovery District or grabbing coffee near Spadina. But honestly? It’s only hard because the bridge between a brilliant schematic on your laptop and a physical, pulsing circuit board is usually a logistical nightmare. That's where custom pcb prototyping toronto radiocord technologies comes into the picture. People are tired of waiting six weeks for a board from overseas only to realize they swapped the TX and RX lines on a UART header. It’s soul-crushing.

Toronto has become this weird, beautiful hub for IoT and medical tech. Because of that, the demand for rapid iteration has absolutely exploded. Radiocord Technologies has carved out a niche by focusing on that "messy middle"—the phase where you aren't ready for a 10,000-unit run in Shenzhen, but you’re way past breadboarding in your basement.

The Problem With "Cheap" Prototyping

We've all done it. You find a site that offers ten boards for five bucks. You upload your Gerber files, pay the shipping, and wait. And wait. By the time the boards arrive, you’ve already found three bugs in your code that require a hardware revision anyway.

Local prototyping changes the math. When you work with a firm like Radiocord in the GTA, the feedback loop shrinks from weeks to days, or even hours. It's about proximity. It’s about being able to actually talk to the engineer who is looking at your trace widths and saying, "Hey, this 0.4mm pitch BGA is going to be a nightmare to solder without a dedicated stencil." That kind of insight is basically non-existent when you’re just another order number in a massive offshore queue.

What Makes Custom PCB Prototyping Toronto Radiocord Technologies Different?

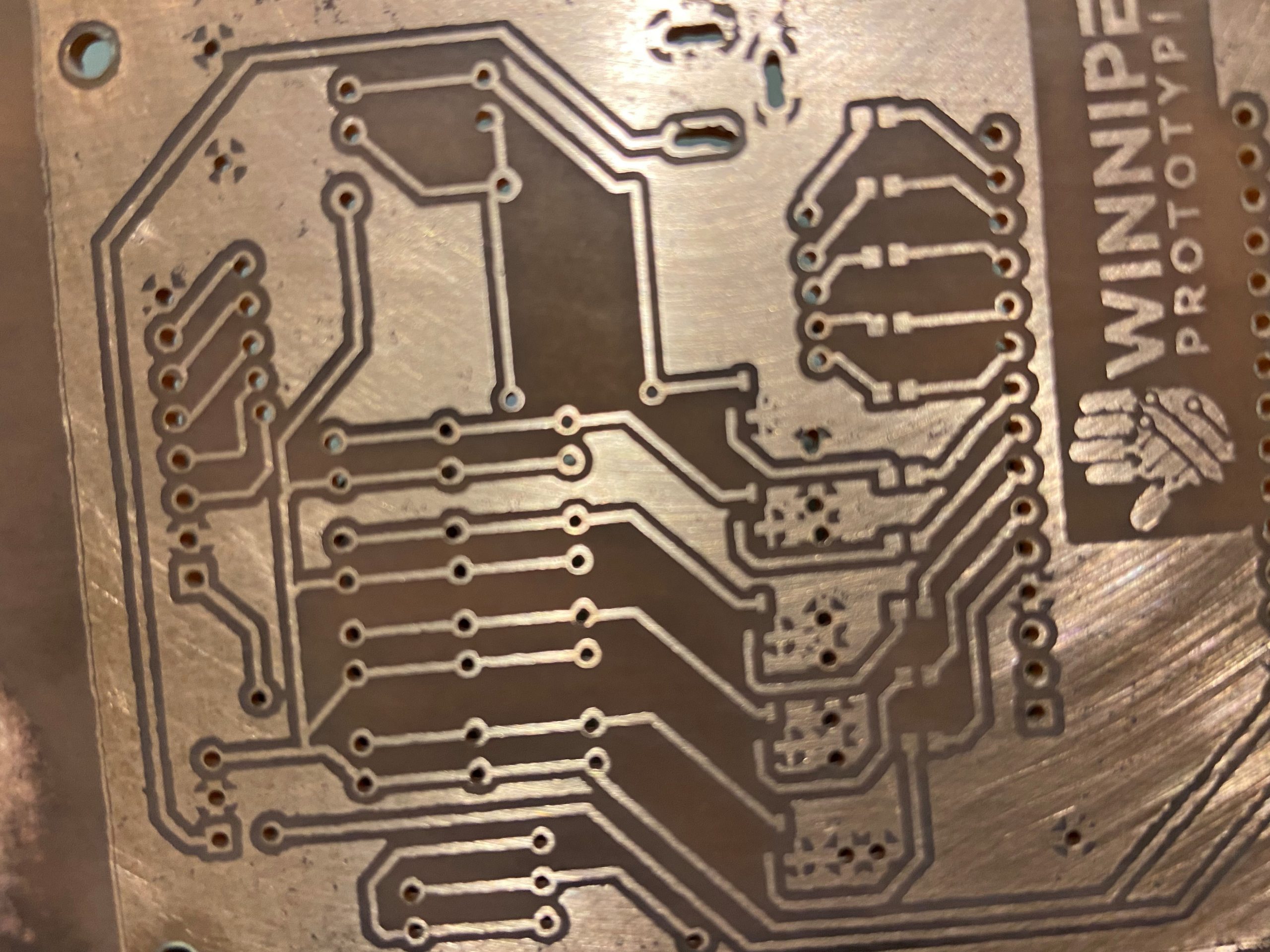

Most people think a PCB is just some fiberglass and copper. It’s not. It’s a thermal management system, a structural component, and a high-speed signal environment all rolled into one. Radiocord tends to focus on the high-complexity stuff. We’re talking multi-layer stacks, impedance control for high-speed differential pairs, and rigid-flex designs that need to fit into tiny wearables.

Toronto’s tech sector, especially around the University of Toronto and the surrounding startup incubators, pushes for edge-case engineering. You might be working on a neural interface or a specialized sensor for underwater drones. These aren't "standard" boards. They require specific substrate materials like Rogers for RF applications or heavy copper for power electronics.

The reality of custom pcb prototyping toronto radiocord technologies is that it bridges the gap between design and assembly. It’s one thing to get a bare board; it’s another to get it populated with components that are currently stuck in a global supply chain bottleneck. Local shops often have "attic stock" or better relationships with local distributors like Digikey or Mouser, helping you find workarounds for that one out-of-stock voltage regulator that’s holding up your entire project.

The Hidden Costs of Waiting

If your burn rate is $10,000 a month and you’re waiting three weeks for a prototype, that’s $7,500 down the drain just for the "privilege" of saving a few hundred bucks on fabrication. It makes no sense.

Speed is the only currency that matters in prototyping.

When you iterate fast, you fail fast. And failing fast is the only way to eventually succeed. I’ve seen teams spend six months on a single revision because they were obsessed with lowering the unit cost of the prototype. Don't do that. Your prototype is supposed to be expensive; your production run is where you save money. Custom pcb prototyping toronto radiocord technologies allows for that "fail-forward" mentality because the friction of ordering is so much lower.

Understanding the Technical Nuance

Let's get into the weeds for a second. Signal integrity is a massive issue as we move toward 5G and high-speed IoT. If your trace lengths aren't matched or if your ground plane is Swiss cheese, your board is basically a very expensive paperweight.

- Controlled Impedance: Crucial for USB 3.0, HDMI, or DDR memory interfaces. If the fab house doesn't verify the dielectric constant of the prepreg, your 50-ohm line might actually be 65 ohms. Everything breaks.

- Blind and Buried Vias: When you’re trying to pack a lot of tech into a small space, you can’t have vias going through all 8 layers. Local high-end prototyping shops handle these complex drilling processes much more reliably for small batches.

- Solder Mask Precision: High-density interconnect (HDI) designs need perfect registration. If the mask is off by even a few microns, you’re looking at shorts across your fine-pitch components.

Radiocord Technologies understands that in Toronto’s competitive landscape, you aren't just looking for a board; you’re looking for an engineering partner. They see the errors in your design rules before the drill even touches the laminate.

Why the GTA is the New Hardware Valley

It’s not just about the boards themselves. It’s the ecosystem. Within a 50km radius of the CN Tower, you have world-class machine shops, injection molding facilities, and firmware experts. Using custom pcb prototyping toronto radiocord technologies puts you in the center of that web. You can get your PCB made, walk it over to a 3D printing lab for a fit-check in a custom enclosure, and then meet a VC for lunch on King Street.

There’s a specific kind of "Toronto Quality" that’s emerging. It’s a mix of rigorous academic standards and a gritty, startup-heavy hustle. We aren't just making gadgets; we're making infrastructure.

The Manufacturing Process Simplified

Basically, the process starts with your EDA tool—Altium, KiCad, Eagle, whatever you use. You export your Gerbers and your Bill of Materials (BOM). But here is the kicker: a good prototyping partner doesn't just "print" what you send. They perform a DFM (Design for Manufacturing) check.

They might notice that your thermal reliefs are too small or that your mounting holes are dangerously close to a high-voltage trace. In the context of custom pcb prototyping toronto radiocord technologies, this interaction is the "secret sauce." It saves you from the "it worked on my simulator" syndrome.

Common Misconceptions About Local Prototyping

"It's too expensive."

Is it? Compared to a two-week delay in your product launch? No way.

👉 See also: How to Access Pornhub in Florida: What Most People Get Wrong

"They can't handle high volumes."

True, but that's not the point. Prototyping is about validation. Once the design is bulletproof, then you move to high-volume CMs (Contract Manufacturers).

"I can just use a desktop PCB mill."

Good luck with via plating and solder masks. Desktop mills are great for basic hobbyist projects, but for anything involving SMT (Surface Mount Technology) or multi-layer signals, they simply can't compete with professional-grade chemical etching and plating.

Moving Forward With Your Design

If you’re sitting on a design right now, the worst thing you can do is sit on it for another week "polishing" it. Perfection is the enemy of the prototype. Get a version out. Get it in your hands.

- Check your footprints: Seriously, print your layout on a piece of paper at 1:1 scale and place your components on top. It’s the easiest way to catch a wrong package size.

- Verify your BOM: Ensure your components are actually in stock. There is nothing worse than getting a beautiful PCB back only to find out the main microcontroller has a 52-week lead time.

- Communicate with the fab: Tell them what the board is for. If it’s a high-vibration environment or needs to handle high heat, that changes how they manufacture it.

Custom pcb prototyping toronto radiocord technologies provides the physical foundation for the next wave of Canadian innovation. Whether it’s a medical device that saves lives or a sensor that tracks climate change, it all starts with a single, well-made prototype.

Next Steps for Your Project

The most effective way to move forward is to prepare a "clean" handoff package. This means your Gerber X2 files, a clear drill map, and a BOM with manufacturer part numbers (MPNs), not just generic descriptions like "10k resistor." Reach out to a local specialist and ask for a DFM review early in the process, rather than after you've finalized everything. This proactive approach usually uncovers layout issues that would otherwise lead to a "dead on arrival" board. Finally, prioritize a "functional minimum" for your first spin—get the core circuit working before you try to cram every secondary feature onto the copper.