Ever tried to buy a "standard" circuit board for a project that was anything but standard? It’s a nightmare. You’re basically trying to shove a square peg into a round hole, hoping the firmware doesn't crash the moment things get a little warm or a little fast. This is exactly where custom electronics design radiocord technologies steps in, though most people outside the high-end engineering world haven't even heard the name yet. It’s not just about soldering components onto a green slab of fiberglass. Honestly, it’s about solving the specific, messy problems that off-the-shelf Chinese imports simply can’t touch.

Customization is the word of the decade. But in hardware? It's expensive. It's risky. Or at least, it used to be.

What’s Actually Happening with Radiocord?

When we talk about Radiocord, we aren't talking about a generic consumer brand you’ll find at a big-box retailer. It’s a specialized niche focusing on ruggedized, high-frequency, and signal-critical applications. Think of it like this: if you’re building a smart toaster, you don't need this level of engineering. But if you're building a communication array that has to survive 50-degree temperature swings while maintaining a 5GHz signal without dropping a single packet? Yeah, you’re looking at custom electronics design radiocord technologies.

The core of the "Radiocord" philosophy is signal integrity. Most engineers struggle with "noise"—that annoying electromagnetic interference (EMI) that messes with data. In a world where everything is wireless, the air is crowded. Radiocord-style design uses specific trace routing and shielding techniques that act like a soundproof room for your data. It’s quiet. It’s clean. It works when the environment is screaming with interference.

The Problem With Generic Boards

Let's be real for a second. Most "custom" designs today are just modified reference designs from chip manufacturers like Texas Instruments or STMicroelectronics. There’s nothing inherently wrong with that, but it's lazy. It’s like buying a pre-built house and just painting the front door red. Radiocord technologies go deeper. They look at the substrate—the literal material the board is made of—to ensure thermal expansion doesn't crack the solder joints over five years of hard use.

The Engineering Reality: It’s All About the Layout

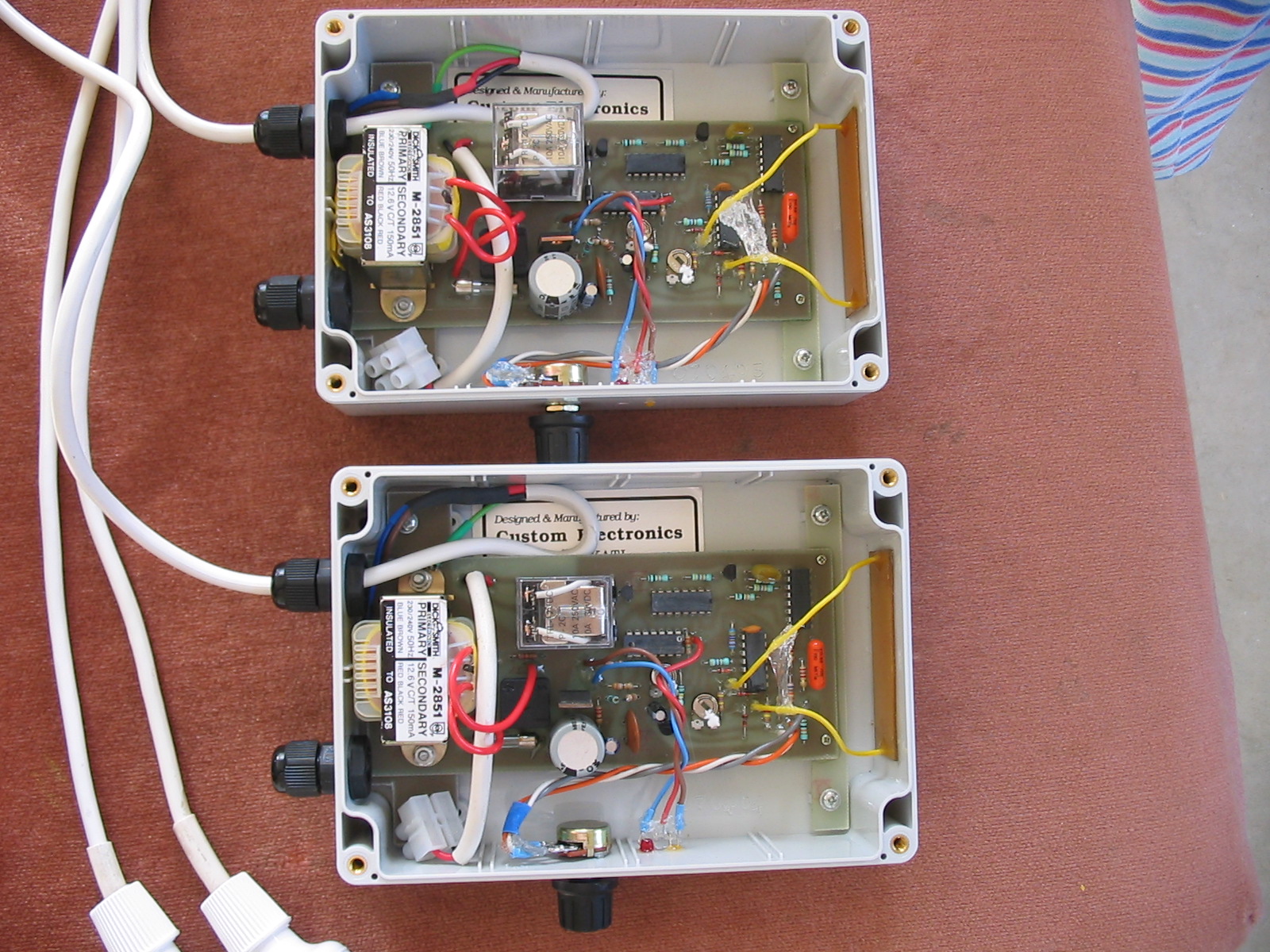

If you've ever looked at a modern PCB, it looks like a miniature city. But in custom electronics design radiocord technologies, that city is planned with the precision of a Swiss watch.

📖 Related: New Update for iPhone Emojis Explained: Why the Pickle and Meteor are Just the Start

One of the biggest hurdles in modern tech is heat. We’re cramming more processing power into smaller boxes. Standard designs rely on bulky fans or heavy heatsinks. Radiocord-focused engineers often use "thermal vias"—tiny copper-lined holes that act like heat pipes—to pull warmth away from sensitive chips and dump it into the ground plane. It’s elegant. It’s invisible. It means your device doesn't melt when it actually has to do some work.

Mixed-Signal Challenges

This is where things get tricky. Most devices today are "mixed-signal," meaning they have both analog (like audio or sensors) and digital (the 1s and 0s) parts. Digital signals are loud and "trashy" in terms of electrical noise. Analog signals are delicate.

If you put them too close together on a board without proper isolation, the digital noise "bleeds" into the analog signal. You get hiss in your audio or jitter in your sensor readings. Custom electronics design radiocord technologies uses specialized ground planes—think of them as electrical moats—to keep these two worlds separate. It sounds simple, but the math behind it is staggering. We're talking about Maxwell's Equations in real-time practice.

Why Should You Even Care?

You might think, "I'm not an engineer, why does this matter to my business?" Well, if you’re a stakeholder in a company building proprietary hardware, "off-the-shelf" is your biggest liability.

- Obsolescence: If you use a generic board, and that manufacturer goes bust or stops making that specific revision, your product is dead. Custom design means you own the IP. You control the supply chain.

- Efficiency: Standard boards have parts you don't need. Those parts suck power. In battery-operated devices, custom electronics design radiocord technologies can often double or triple battery life just by stripping away the "fat" of a generic design.

- Size: You can't fit a Raspberry Pi into a sleek, wearable medical device. You just can't.

The Secret Sauce: Rapid Prototyping and Iteration

In the old days (meaning like, five years ago), getting a custom board made took months. You’d send files to a fab house, wait three weeks, get the boards back, find a mistake, and cry. Today, the Radiocord approach integrates "Agile" hardware development.

👉 See also: New DeWalt 20V Tools: What Most People Get Wrong

We’re seeing the rise of desktop PCB milling and high-end 3D circuitry printing. While these aren't ready for mass production, they allow designers to test a "Radiocord" layout in 24 hours. You can fail fast. You can find out that your antenna placement is garbage on Tuesday and have a fixed version running on Wednesday.

Real-World Example: Industrial IoT

Imagine a factory floor. It’s hot. There are massive electric motors creating giant magnetic fields. A standard Wi-Fi module will fail here in minutes. By utilizing custom electronics design radiocord technologies, a firm can design a sensor node with specific "differential signaling" that ignores the magnetic noise from the motors. That’s the difference between a smart factory that actually works and a pile of expensive e-waste.

Common Misconceptions About Custom Hardware

People think custom means "more expensive." On a per-unit basis for the first 100 units? Absolutely. It’s pricey. But when you scale to 10,000 units? The custom board is almost always cheaper. Why? Because you aren't paying for features you don't use. You aren't paying for a generic HDMI port that your device doesn't even have a screen for.

Also, people think custom hardware is harder to certify. Actually, it's often easier. If you design with FCC or CE compliance in mind from day one—using the shielding techniques inherent in Radiocord designs—you breeze through testing. Trying to "fix" a noisy, generic board to pass FCC testing is a special kind of hell.

The Future of Radiocord Tech

We’re moving toward a world of "edge computing." This means instead of sending all data to the cloud, the device does the thinking itself. This requires serious horsepower.

✨ Don't miss: Memphis Doppler Weather Radar: Why Your App is Lying to You During Severe Storms

Current trends in custom electronics design radiocord technologies are leaning heavily into System-on-Module (SoM) integration. Instead of designing the CPU and RAM from scratch (which is insane for most people), designers use a tiny, pre-certified module and build a highly specialized "carrier board" around it. It’s the best of both worlds: the reliability of a proven chip with the surgical precision of custom IO and power management.

Actionable Steps for Your Next Project

If you're looking at moving toward a custom hardware solution, don't just jump in headfirst. It’s a marathon, not a sprint.

- Audit Your Current Hardware: Are you using more than 60% of the features on your current board? If not, you're wasting money and battery life.

- Prioritize Signal Integrity: If your device has any wireless component (Wi-Fi, Bluetooth, LoRa, 5G), the layout is more important than the components themselves. Look for designers who understand Radiocord principles.

- Think About the Housing Early: Don't design the board and then try to find a box for it. In custom electronics design radiocord technologies, the enclosure and the PCB are a single system. The box affects the heat, and the heat affects the box.

- Own Your Files: Ensure that you own the Altium or KiCad source files. Never let a design firm hold your "source code" hostage.

- Start with a Discovery Phase: Before a single trace is drawn, spend two weeks on a feasibility study. It sounds boring. It saves thousands of dollars.

The world is only getting more connected. The "easy" hardware has all been built. What’s left are the hard problems—the ones that require specialized signals, rugged builds, and insanely efficient power profiles. That’s the playground of custom electronics design radiocord technologies. It’s not just about making a gadget; it’s about making a tool that doesn't quit when the environment gets ugly.

Invest in the foundation. The silicon is only as good as the traces connecting it.