Ever tried putting together a piece of Swedish furniture with a set of American wrenches? It’s a nightmare. You’re staring at a bolt that’s just a hair too big for a 1/2-inch socket, but your 13mm feels loose, and suddenly you’re stripping the head. This is exactly why a reliable inches to millimeters chart isn't just some boring school tool; it’s basically survival gear for anyone who builds, fixes, or designs things in a world that can't decide on a single measurement system.

Measurements matter. A lot.

The United States, Liberia, and Myanmar are the lonely trio still clinging to the imperial system while the rest of the planet moves in base-ten logic. Because we live in a global economy, you’re constantly jumping between the two. You buy a TV in inches, but the VESA mount screws are almost certainly metric. Your car might have a "domestic" badge, but half the components under the hood were likely manufactured in a factory using millimeters. It's a mess. Honestly, trying to do the math in your head—multiplying by 25.4 every time—is a one-way ticket to a headache and a ruined workpiece.

The math behind the inches to millimeters chart

Let's get the technical stuff out of the way first. One inch is exactly 25.4 millimeters. Not "about" 25.4. It is an international standard established in 1959. Before that, the US inch and the UK inch were actually slightly different, which caused all sorts of chaos in high-precision manufacturing. Now, it’s fixed.

To go from inches to millimeters, you multiply by 25.4. To go back, you divide. Simple, right? Except when you’re dealing with fractions.

Fractions are the worst. If you see 5/16 of an inch, you first have to convert that to a decimal (0.3125) before you even touch the metric conversion. That extra step is where most people trip up. An inches to millimeters chart does the heavy lifting so you don't have to keep a calculator covered in sawdust or grease on your workbench.

Common fractional conversions you'll actually use

Think about the stuff you see at the hardware store.

A 1/4 inch bolt is basically 6.35 mm. If you’re looking for a metric equivalent, a 6mm bolt is close but won't fit the same hole perfectly.

Then you have 1/2 inch. That’s exactly 12.7 mm. You'll often see people try to swap a 1/2 inch wrench for a 13mm one. It works most of the time, but that 0.3mm difference is enough to round off the corners of a stubborn nut if you aren't careful.

What about 3/4 inch? That’s 19.05 mm. In the automotive world, a 19mm socket is the bread and butter of lug nuts. If you have an older American truck, you might need that 3/4, but on almost anything made in the last twenty years, you're grabbing the 19mm.

1/8 inch is 3.175 mm.

3/8 inch is 9.525 mm.

5/8 inch is 15.875 mm.

1 inch is 25.4 mm.

Notice how the numbers get messy? That's the beauty of the metric system—it’s just clean decimals. But since we’re stuck with the legacy of the imperial system, the chart is your bridge between "kinda close" and "perfectly flush."

Why precision isn't optional in 2026

We live in the era of 3D printing and CNC machining. If you're designing a part in Fusion 360 or Shapr3D, a mistake of half a millimeter is the difference between a part that snaps into place and a piece of plastic scrap.

I’ve seen hobbyists spend hours printing a case for an Arduino board only to realize they used an imperial ruler to measure a metric component. The ports didn't line up. Total waste of time. When you use an inches to millimeters chart, you’re double-checking your reality.

Engineers at NASA learned this the hard way back in 1999 with the Mars Climate Orbiter. One team used metric units (newtons), and the other used imperial units (pound-force). The spacecraft got too close to the Martian atmosphere and disintegrated. It was a $125 million mistake. Your kitchen remodel might not cost a hundred million dollars, but measuring your cabinet gaps wrong because you guessed the metric-to-imperial shift will definitely feel like a disaster when the contractor shows up.

Understanding the "Close Enough" Trap

There’s this thing in tools called "interchangeability." Some sizes are so close that the human eye can't really tell the difference, but the metal can.

Take the 5/16 inch and the 8mm.

5/16" is 7.9375 mm.

That is a difference of only 0.0625 mm.

In most casual DIY scenarios, an 8mm wrench will work on a 5/16" bolt. But if that bolt is rusted tight? You’ll feel that tiny bit of "slop" or play in the tool. That’s when the tool slips, you bark your knuckles, and you start questioning your life choices.

Another common overlap is 7/16 inch and 11mm.

7/16" is 11.1125 mm.

Here, the 11mm wrench is actually slightly smaller than the bolt. It won't even slide on. You might think the bolt is just "dirty" and try to hammer the wrench on. Don't do that. Consult the chart.

How to read a conversion chart without getting a headache

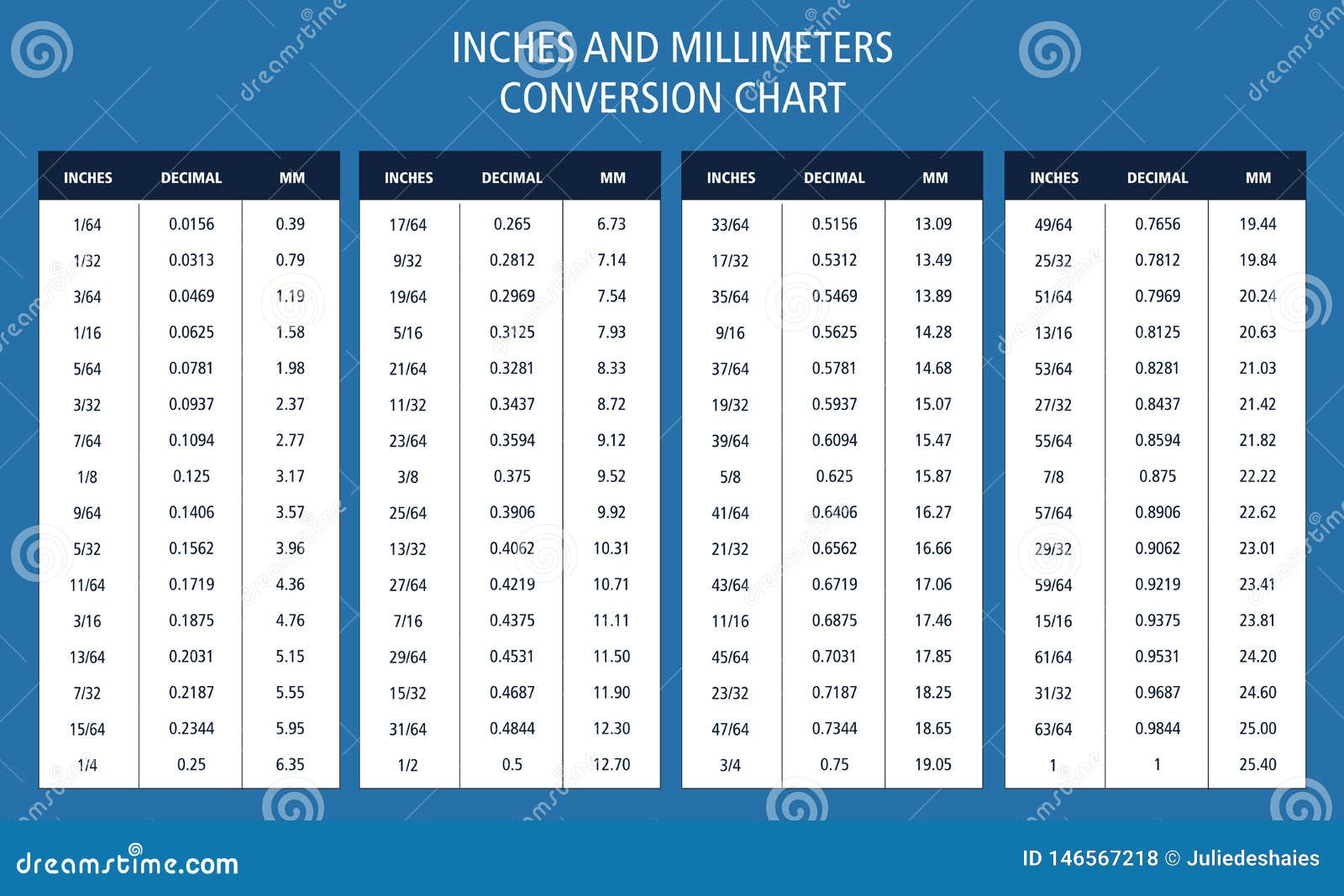

Most charts are laid out in columns. You’ll have the fraction on the left, the decimal equivalent in the middle, and the millimeter total on the right.

Look for the "step" of the chart.

High-precision charts go down to 1/64th of an inch.

1/64" = 0.0156" = 0.3969 mm.

Unless you’re a machinist or a jeweler, you probably don't need that level of granularity. For most of us, a chart that moves in 1/16th or 1/32nd increments is the "sweet spot" for readability.

Practical applications in everyday life

It’s not just for the garage.

Think about photography. Lens filters are measured in millimeters (58mm, 77mm, 82mm), but sometimes tripod threads are listed in fractions of an inch (1/4-20 or 3/8-16). If you're trying to rig up a custom camera mount, you have to know how these two worlds collide.

Or consider jewelry. If you’re buying a ring or a chain from an international seller, they might list the width in millimeters. A 2mm chain sounds thin—and it is—but how thin? Well, 2mm is roughly 5/64 of an inch. Knowing that helps you visualize what you're actually spending money on.

Even in the kitchen, it comes up. If you have a recipe from a European blog asking for a 20cm pan, and you’re staring at your 8-inch skillet, are they the same?

8 inches x 25.4 = 203.2 mm (or 20.32 cm).

Close enough for a frittata? Definitely.

Beyond the basics: Thousands of an inch

In the machining world, people talk about "thou" (one-thousandth of an inch).

0.001 inches is 0.0254 mm.

To put that in perspective, a human hair is roughly 0.002 to 0.004 inches thick. When you're working at this level, an inches to millimeters chart usually becomes a decimal-to-metric reference. Machinists often use "dial calipers" that can switch modes with a button, but having a physical chart taped to the wall is a failsafe. Batteries die; printed charts don't.

The cultural shift toward metric

Let's be real: the world is going metric. Even in the US, the medical field, the military, and the scientific community have already made the jump. It’s more logical. Everything is a multiple of ten.

However, our infrastructure is built on inches. Houses are built with 2x4s (which aren't actually 2 inches by 4 inches, but that's a different rant) and 16-inch on-center studs. Roads are measured in miles. We aren't changing the physical layout of our cities anytime soon. This means the need for conversion isn't going away. It’s a dual-language world, and the chart is your dictionary.

Troubleshooting your measurements

If you're using a chart and things still aren't fitting, check your tools. Cheap tape measures often have a "hook" at the end that moves. People think it's broken, but it’s actually designed to move by the thickness of the metal hook itself so you get an accurate reading whether you're pushing against a wall or hooking onto the end of a board.

Also, watch out for "rounding." Some cheap charts round 25.4 to 25.

Don't use those.

Over a long distance, that 0.4mm error compounds. If you measure 10 inches using a rounded "25" factor, you’re off by 4 millimeters. That’s nearly a quarter of an inch. In construction or crafting, that’s a massive gap.

💡 You might also like: Why Halloween Poems for Kids are Still the Best Way to Celebrate October

Digital vs. Analog: Why paper still wins

I love my phone as much as anyone, but unlocking a screen with sweaty or dusty hands just to check a measurement is annoying. A physical inches to millimeters chart printed on a magnet or a piece of cardstock is superior. You can glance at it while holding a piece of wood in one hand and a pencil in the other.

It's about cognitive load. You want to spend your brainpower on the project, not on the math.

Actionable steps for your next project

Stop guessing and stop "eyeballing" it. Here is how you actually integrate this into your workflow:

- Print a High-Resolution Chart: Don't just look at one on a screen. Print a version that includes fractions, decimals, and millimeters. Tape it to the inside of your toolbox or the wall of your craft room.

- Buy a Digital Caliper: If you do any kind of precise work, a $20 digital caliper is a game-changer. Most of them have a "mm/inch" button that allows you to see the conversion in real-time.

- Check for "Metric-Equivalent" Fasteners: If you’re building something and the instructions call for a specific millimeter size, try to buy that exact size. If you must substitute with an imperial size from your junk drawer, use your chart to find the one with the smallest "delta" (the smallest difference).

- Mark Your Tools: If you have a set of wrenches that are confusing, use a paint pen to mark the closest metric/imperial neighbors. For example, mark your 19mm and 3/4" with the same color of tape so you know they are roughly interchangeable in an emergency.

- Memorize the Anchors: You don't need to know the whole chart. Just remember that 1/4" is roughly 6mm, 1/2" is roughly 13mm, and 1" is 25.4mm. Having these "anchor points" in your head makes it easier to spot when a calculation feels wrong.

The world won't agree on a measurement system tomorrow. Until then, keep your chart handy, measure twice, and let the math do the heavy lifting.