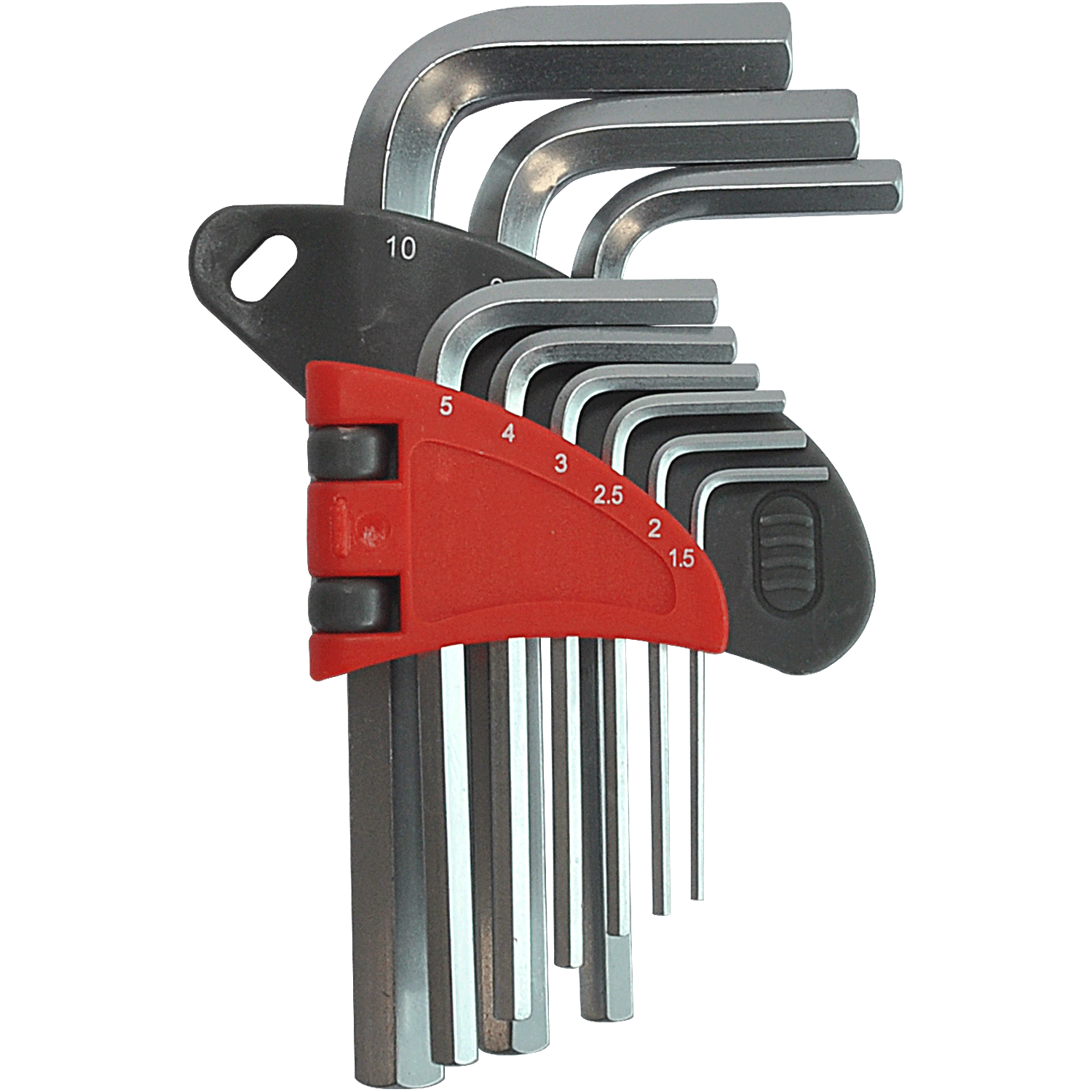

You’re staring at a flat-pack dresser from IKEA or maybe a loose adjustment screw on a high-end mountain bike. Everything stops because you can't find that one specific L-shaped piece of metal. It’s frustrating. An allen key hex set is arguably the most basic tool in your drawer, yet it's the one that causes the most headaches when the tolerances are just a tiny bit off.

We call them Allen keys, hex keys, or even Zeta keys if you’re being fancy. They are deceptively simple. A hexagonal cross-section. Usually 90 degrees of bend. That’s it. But if you’ve ever stripped a bolt head on a $2,000 piece of machinery because you used a 5mm key on a 3/16-inch bolt, you know the stakes are actually weirdly high.

The metric vs. SAE headache is real

Honestly, the biggest mistake people make is assuming "close enough" works with an allen key hex set. It doesn’t.

The world is split between Metric (millimeters) and SAE (inches). They look identical to the naked eye when they're small. But try using an 8mm key in a 5/16-inch socket. The 5/16-inch is roughly 7.93mm. That tiny 0.07mm gap is exactly where stripped bolts are born. Once you round off the internal corners of a hex fastener, you're moving into "drill it out and cry" territory.

Real experts, like the folks over at Bondhus or Wera, have spent decades obsessed with "fitment." Bondhus actually uses a specific type of steel called Protanium which they claim is the hardest and most ductile in the industry. It’s not just marketing fluff. If a key is too brittle, it snaps and leaves a stump inside your bolt. If it’s too soft, it twists like a noodle. You want that middle ground where the tool gives you a little "spring" feedback before it breaks.

Why the "Ball End" actually matters

Most modern sets come with a straight hex on the short arm and a rounded "ball" on the long arm. This was a game-changer patented by Bondhus back in the 60s. It allows you to enter the bolt at an angle—up to 25 degrees usually.

It's a lifesaver in tight engine bays or inside computer cases. But here is the secret: never, ever use the ball end to break a bolt loose or for the final tighten. The surface area contact is significantly lower than the flat end. If you apply 20 foot-pounds of torque to a ball end, you’re basically asking for it to shear off. Use the short, stubby end for the heavy lifting. Use the ball end for the spinning.

🔗 Read more: The Recipe With Boiled Eggs That Actually Makes Breakfast Interesting Again

Color coding isn't just for aesthetics

You've probably seen those rainbow-colored sets from Wera (the SPKL series). Purists used to laugh at them. "Why do my tools need to look like a bag of Skittles?" they’d ask. Then they tried to find a 4mm key in a dark toolbox at 10 PM.

Color coding saves time. Period. When you know that "blue" is always your 6mm and "yellow" is your 3mm, your brain stops searching for tiny etched numbers that are usually covered in grease anyway. Also, the sleeves on these high-end sets make the keys thicker and easier on your palms. If you're tightening fifty bolts in a row, those thin, bare-metal keys will leave deep red welts on your skin.

The torque problem nobody talks about

Precision is everything. In the aerospace world or even high-level cycling, an allen key hex set is often just a precursor to a torque wrench.

Most people over-tighten hex bolts. Because the tool is small, we feel like we need to crank it. But because the force is concentrated on six small points of contact, it’s incredibly easy to deform the fastener. This is especially true with stainless steel bolts, which are softer than the alloy steel used in most keys.

If you are working on carbon fiber—like a bike frame or a high-end tripod—stop guessing. Use the hex key to get it snug, then finish it with a dedicated torque limiter. Carbon doesn't creak before it breaks; it just explodes.

Cheap sets vs. the "Buy it once" philosophy

You can buy a hex set at a gas station for three dollars. It’ll be made of soft "pot metal" and the sizing will be "approximate."

💡 You might also like: Finding the Right Words: Quotes About Sons That Actually Mean Something

Avoid them.

Cheap keys are often plated in chrome that flakes off. Those flakes are razor-sharp. Even worse, if the plating is thick, the manufacturer might have made the underlying steel too small to compensate, leading to a loose fit.

If you're serious, look for "Black Oxide" finishes or "GoldGuard." These aren't just for show; they provide corrosion resistance without adding thickness that ruins the tool’s precision. Brands like Eklind (made in the USA) or PB Swiss (the literal gold standard) are where the pros gravitate. PB Swiss tools are so precise they actually have serial numbers on individual hex keys. That’s the level of obsession we’re talking about.

How to save a stripped hex bolt

It happens to the best of us. You felt the "pop," but it wasn't the bolt loosening—it was the tool spinning inside the head. Before you reach for the drill, try these:

- The Rubber Band Trick: Place a wide, flat rubber band over the hole and push the hex key in. The rubber fills the gaps.

- Valve Grinding Compound: A tiny dab of this gritty paste on the tip of your key increases friction exponentially.

- The Torx Pivot: Sometimes, you can hammer a slightly oversized Torx (star) bit into a stripped hex hole. The points of the star bite into the metal and give you just enough grip to back it out.

- Heat: If there’s Loctite involved, a mini butane torch is your best friend. Heat softens the thread-locker.

Maintaining your set

Steel rusts. Even the good stuff.

If you keep your allen key hex set in a damp garage, they will eventually pit. A light wipe-down with a rag dampened with WD-40 or 3-in-1 oil once a season is basically all they need.

📖 Related: Williams Sonoma Deer Park IL: What Most People Get Wrong About This Kitchen Icon

Also, keep them in their holder. A hex set with a missing 5mm key is like a deck of cards missing an Ace. It’s technically there, but it’s useless when you actually need to play the game. Most modern holders have a locking mechanism or a magnet—use it.

Practical Next Steps for Your Toolkit

If you're looking to upgrade or just starting out, don't just buy the first thing you see.

First, check your most common use case. If you're a homeowner doing furniture and basic repairs, a folding "multitool" style set is convenient because you can't lose the individual keys. However, if you're working on machinery or bikes, you absolutely need the L-shaped individual keys for the reach and the torque.

Identify if you need Metric or SAE. If you live in the US, you honestly need both. If you're in Europe or Asia, you can usually get away with just Metric. Look for a set that includes the "in-between" sizes like 7mm or 9mm, which are becoming more common in automotive brake calipers.

Finally, check the warranty. Companies like Bondhus offer a lifetime replacement. If you break it, they ship you a new one. That's the kind of reliability that turns a simple piece of bent metal into a lifelong companion in the workshop.