You're scrolling through Zillow or Redfin, and the numbers just don't make sense anymore. A starter home in a decent school district costs as much as a small island did ten years ago. It’s exhausting. Most people think they need 2,500 square feet to breathe, but honestly, that’s just more floor to vacuum and more rooms to fill with stuff you don't use. Enter the 1000 square foot prefab house. It sounds like a compromise. It feels like you’re giving up on the "American Dream" of a sprawling mansion, but the reality is actually way more interesting.

The industry is changing. Fast.

The weird math of the 1000 square foot prefab house

Let’s talk money because that’s usually where these conversations start. People assume prefab means "cheap." That is a massive misconception. If you're looking for a bargain-basement mobile home from the 1970s, you’re in the wrong place. A high-quality 1000 square foot prefab house from a company like Plant Prefab or Blu Homes can actually cost more per square foot than a traditional "stick-built" home. Why? Precision. These things are built in climate-controlled factories where tolerances are measured in millimeters, not "good enough" inches.

You’re paying for the lack of headaches. No rain-delayed framing. No contractor disappearing for three weeks to work on another job. No mold growing inside your walls because a surprise thunderstorm hit before the roof was on.

What does 1,000 square feet actually feel like?

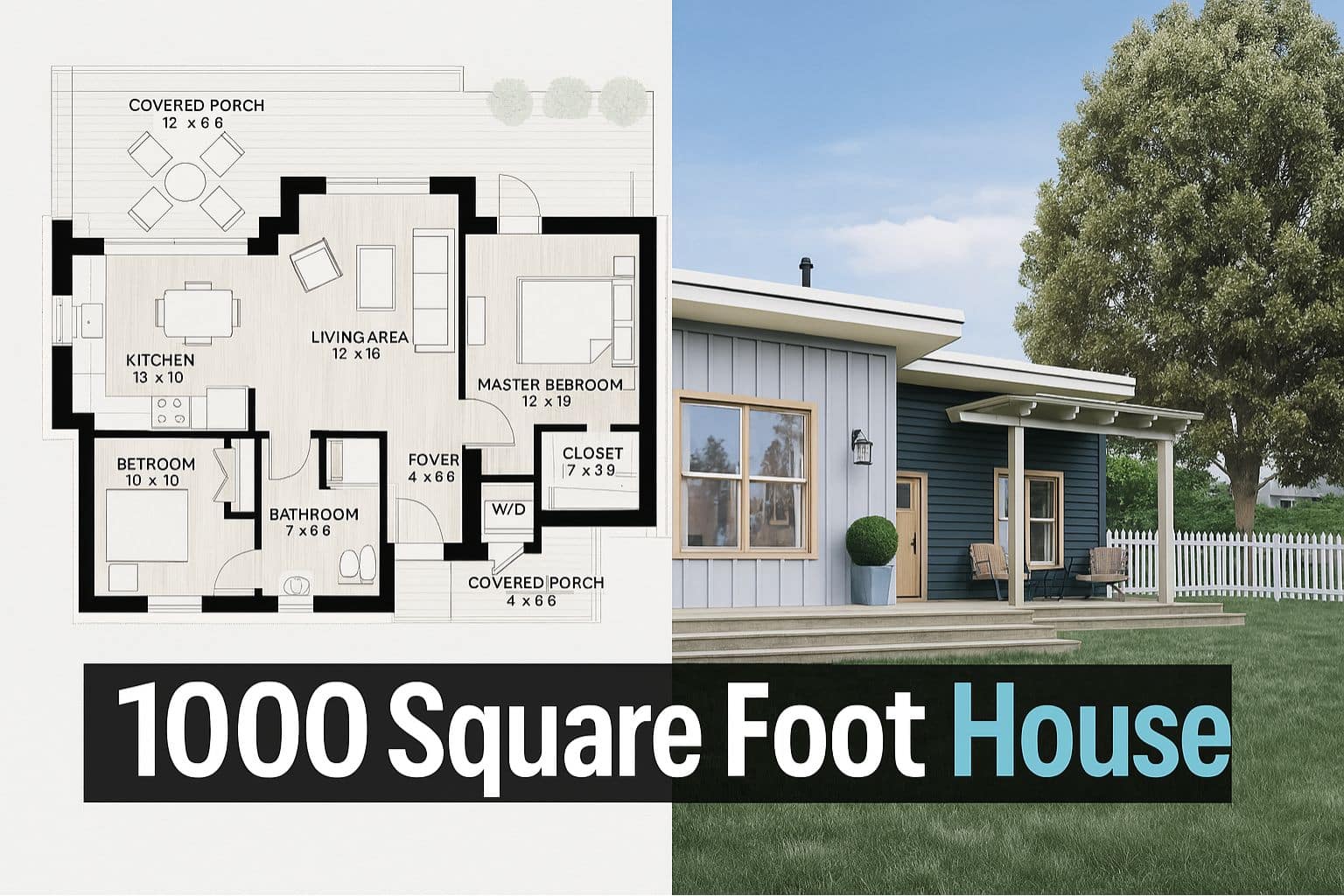

It’s bigger than you think, provided the designer wasn't asleep at the wheel. In a standard old-school house, you lose a ton of space to hallways. Hallways are dead zones. They’re just transit paths for your laundry basket. Modern prefab designers, like those at Ma Modular or Go Home by GO Logic, basically delete hallways. They use "open-concept" layouts where the kitchen flows into the dining area, which flows into the living room. Suddenly, that 1000 square foot prefab house feels like 1,300.

Think about it. Two bedrooms, two baths, and a Great Room. That’s plenty for a couple, a small family, or someone looking to downsize without feeling like they’re living in a closet.

The sustainability trap

We hear "eco-friendly" and we roll our eyes. It’s a marketing buzzword. But in the prefab world, sustainability isn't just about feeling good; it’s about physics. When you build in a factory, waste is almost zero. They know exactly how much lumber or steel is needed. In traditional construction, about 30% of materials end up in a dumpster. That’s insane.

Then there’s the energy bill. A 1000 square foot prefab house is often built to Passive House standards. This means the insulation is so thick and the sealing is so tight that you could basically heat the place with a toaster and a few candles. Okay, maybe that's an exaggeration, but your HVAC system won't be working overtime. Companies like Unity Homes focus specifically on this airtight envelope. You save money every single month. It adds up.

🔗 Read more: Pink White Nail Studio Secrets and Why Your Manicure Isn't Lasting

It isn't all sunshine and rainbows

I have to be honest here: the logistics can be a nightmare. You see a beautiful price tag of $200,000 for a prefab kit and you think, "Great! I can afford that!"

Stop.

That price rarely includes the "site work." You need a foundation. You need a septic system or a sewer hookup. You need to get electricity to the site. And the big one? The crane. To deliver a 1000 square foot prefab house, you usually need a massive semi-truck and a crane that costs thousands of dollars per day to rent. If your lot is on a steep hill or tucked behind a forest of low-hanging trees, you’re going to have a bad time.

Who is actually buying these things?

It’s not just tech bros in Austin or Portland. We're seeing a huge rise in "ADUs" or Accessory Dwelling Units. Think of it as a fancy guest house or a "granny flat." California recently changed its laws to make these way easier to build. People are dropping a 1000 square foot prefab house in their backyard to use as a rental property or a home office that actually feels like a real building.

It’s a smart hedge against inflation.

The "Kit" vs. "Modular" confusion

People use these terms interchangeably, but they shouldn't.

- Modular: The house shows up in big 3D boxes (modules). They are 90% finished. Cabinets are in. Sinks are installed. The crane clicks them together like Legos.

- Panelized/Kit: The walls show up flat on a truck. You still need a crew to put them up. It’s faster than traditional building, but it takes longer than modular.

- The Hybrid: Some companies do a bit of both.

If you want a 1000 square foot prefab house done in weeks, go modular. If you want more customization and have a local contractor you trust, panelized might be the move.

💡 You might also like: Hairstyles for women over 50 with round faces: What your stylist isn't telling you

Finding the right plot of land

You can't just buy a lot and drop a house on it. Zoning is the silent killer of prefab dreams. Some jurisdictions have "minimum square footage" requirements. They literally won't let you build a 1000 square foot prefab house because they want 2,000-square-foot homes to keep property taxes high.

Check the local codes. Look for "minimum dwelling size." Ask about "impact fees." Sometimes the city will charge you $20,000 just for the privilege of connecting to the water line. It’s a gut punch if you haven't budgeted for it.

Design trends that actually work

Small space living requires cleverness. Built-in storage is your best friend. Floor-to-ceiling windows are another trick. If you can see the outside, the room feels infinite. High ceilings—10 feet or more—make a 1000 square foot prefab house feel like a cathedral.

Avoid "dark" finishes. Stick to light woods, whites, and greys. It sounds boring, but it keeps the walls from feeling like they’re closing in on you.

The resale value myth

There used to be a stigma. People thought prefabs wouldn't hold their value. That’s changing because the quality has surpassed many "cookie-cutter" suburban homes built by mass-market developers. A well-maintained 1000 square foot prefab house from a reputable brand holds its value remarkably well. Why? Because the buyer knows it was built in a controlled environment. There’s a "brand name" aspect to it now, almost like buying a Tesla instead of a generic car.

Real-world examples of the 1000 square foot prefab house

Look at the Muji Hut (though usually smaller) or the LivingHome 6 by Plant Prefab. These aren't "trailers." They are architectural statements. They use high-end materials like Western Red Cedar and floor-to-ceiling glass. They are stunning.

Practical steps to take right now

Don't just buy a kit online because the pictures look pretty.

📖 Related: How to Sign Someone Up for Scientology: What Actually Happens and What You Need to Know

First, get your financing in order. Traditional mortgages can be tricky with prefabs. Some banks won't lend until the house is actually on the foundation. You might need a "construction-to-permanent" loan. Speak to a lender who has dealt with modular homes before.

Second, find your land. Do not buy the land until you have a "feasibility study" done. This costs a few hundred bucks but saves you thousands. It tells you if the land can actually support a 1000 square foot prefab house and what the utility hookups will cost.

Third, visit a factory. Most reputable prefab companies will let you tour their facility. If they won't, walk away. You want to see the craftsmanship with your own eyes. Look at the joints. Look at the quality of the windows.

Fourth, hire a local "general contractor" even if the prefab company says they do it all. You need someone on the ground who knows the local building inspectors. Inspectors can be picky. They often don't like "outsiders" bringing in pre-built houses. A local face helps grease the wheels of bureaucracy.

Finally, plan for the "soft costs." Permits, engineering, shipping, and site prep can easily add 50% to the base price of the house. If the house is $150,000, expect to spend $225,000 or more before you're actually moving in.

It’s a journey. It’s not "instant housing." But a 1000 square foot prefab house offers a level of control and efficiency that old-school building just can’t touch. It’s about living smaller so you can live bigger. Less debt, less cleaning, more time outside. That’s the real goal.

Building a home is always a gamble, but with prefab, you’re at least playing with a deck that isn't stacked against you by the weather and human error. Take the leap, but do it with your eyes wide open and your budget triple-checked. It’s worth the effort.

Actionable insights for your prefab journey

- Verify Zoning First: Call the local planning department and ask specifically about ADU or small-footprint modular residential codes before buying any land.

- Budget for the "Hidden 50%": Always assume the sticker price for the prefab unit is only about half of the final "all-in" cost including land, foundation, and utilities.

- Prioritize the Envelope: Choose a manufacturer that emphasizes high-R-value insulation and triple-pane windows; the long-term energy savings in a 1,000-square-foot space are significant.

- Interview the Crane Operator: It sounds niche, but the person delivering your house is the most important person in the process. Ensure they have surveyed your site for overhead wire clearance and soil stability.

- Stick to the Plan: Prefab is cheapest when you don't change the floor plan. Customization in a factory setting kills the "efficiency" price break, so try to find a standard model that works as-is.