You're at the optometrist. You’ve just finished the "better or worse" dance with the phoropter, and now comes the real headache: the frame wall. Rows of acetate and titanium, most of them licensed by the same two or three massive conglomerates like EssilorLuxottica, all carrying price tags that feel like a personal insult. It’s a racket. But for a growing community of makers, engineers, and people who are just tired of being overcharged, the answer isn't a "buy one get one" sale. It’s sitting on their desk. 3D printable glasses frames have moved past the stage of being chunky, neon-colored novelties and are becoming a legitimate way to get custom-fit, high-end eyewear for the cost of a few grams of plastic.

Customization is the big draw here. Most faces aren't symmetrical. One ear might be slightly lower, or your bridge might be wider than the "standard" medium. When you print your own frames, those measurements aren't suggestions; they’re the blueprint. We are talking about a total shift in how we think about medical devices and fashion.

🔗 Read more: Why the Tysons Corner Mall Apple Store Still Matters More Than Any Other

The Material Science of What’s Actually Wearable

Don't just grab a roll of cheap PLA and expect it to work. Honestly, you’ll regret it. PLA is brittle and has a low glass transition temperature, meaning if you leave your custom frames on a car dashboard in July, they’ll turn into a puddle of plastic noodles. If you're serious about 3D printable glasses frames, you need to look at PETG or, better yet, PA12 (Nylon).

Nylon is the gold standard in the industry right now. It's what companies like Mykita or Materialise use for their high-end additive manufacturing lines. It’s flexible. It’s skin-safe. It handles the constant tension of holding a lens in place without snapping. If you're printing at home on an FDM machine, PETG offers a decent middle ground because it has just enough flex to allow for "cold snapping" lenses into the rims, but it lacks the premium powdery finish of an SLS (Selective Laser Sintering) nylon print.

Then there's the resin world. SLA printing can produce frames that look identical to polished acetate. However, you have to be incredibly careful about biocompatibility. You can't just have raw, uncured resin sitting against your skin for 16 hours a day. It’s a recipe for contact dermatitis. You need specialized, biocompatible resins like those produced by Formlabs (specifically their BioMed resins) if you want to avoid a skin rash.

Where to Find Designs That Don't Look Like Science Projects

Most people start at Thingiverse or Printables. It's the logical first step. You'll find a thousand variations of "Wayfarer-style" frames there. But if you want something that actually fits a human face and holds an optical prescription, you have to dig deeper.

Open-source projects like Rodenstock’s older design concepts or community-driven databases offer files that are actually engineered for optical centers. You see, the frame isn't just a fashion choice; it’s a bracket for a medical lens. If the "pantoscopic tilt"—the angle at which the lens sits relative to your eye—is off, you’re going to get headaches.

- Monoqool and Hoet are great examples of brands that pushed the boundaries of what 3D printed eyewear looks like. While they don't give away their STL files for free, studying their hinge designs is a masterclass in additive manufacturing.

- Framy is another platform that has experimented with allowing users to customize geometry before downloading.

- Check out Logic Eyewear for inspiration on how to integrate traditional wire cores into printed temples for better adjustability behind the ear.

The Hinge Headache: To Print or Not to Print?

This is where most beginners fail. They try to print a 3D hinge. It almost never works long-term. 3D printed plastic-on-plastic friction will eventually wear down, and your glasses will start sliding off your nose every time you look at your phone.

The pro move? Use "heat-set inserts" or actual barrel hinges designed for eyewear. You can buy these in bulk from optical supply wholesalers or even sites like AliExpress. You use a soldering iron to gently press the metal hinge into the plastic frame. This gives you a smooth, metal-on-metal flip that feels like a $400 pair of Tom Fords.

📖 Related: iPhone Trade In Plan: Why You Might Be Leaving $500 on the Table

Some makers are getting clever with "compliant mechanisms." These are designs where the flexibility of the plastic itself acts as the hinge. No screws, no metal, just clever geometry. It’s brilliant, but it requires high-quality Nylon. If you try a compliant hinge with PLA, it’ll snap on the third day. Guaranteed.

Getting Your Lenses Into 3D Printable Glasses Frames

"But how do I get my prescription in there?" This is the question that stops most people. Most local optical shops are terrified of 3D printed frames. They’re worried their lens edger will crush your DIY project, and they don't want the liability.

You have two real options. First, you can measure an existing pair of lenses you own and design the frame around them. This is "reverse engineering" and it’s remarkably effective if you have a pair of digital calipers.

The second option is using online services like Lensabl or ReplaceALens. You mail them your 3D printed frames, and they cut lenses to fit them. Just be sure to tell them the material. If they know it’s PETG or Nylon, they can adjust the pressure of their equipment.

The Economics of Printing Your Own Vision

Let's talk numbers. A typical "designer" frame costs about $5 to manufacture. It retails for $200.

A spool of high-quality PETG costs $25 and can print about 40 pairs of frames.

Even if you factor in the cost of a $300 printer and $80 for professional lenses, you break even by the second pair. Plus, when you sit on your glasses or the dog decides they’re a chew toy, you don't cry. You just hit "print" and go back to work.

There's a psychological shift that happens when you stop seeing your glasses as a precious, fragile investment and start seeing them as a replaceable, customizable interface for your face. You can have a "subtle" pair for the office and a "loud" architectural pair for the weekend, all using the same prescription lenses if you design the frames to be interchangeable.

Finishing and Post-Processing: The Secret Sauce

Raw 3D prints look like 3D prints. You can see the layer lines. If you want that "boutique" look, you have to put in the work.

💡 You might also like: Wait, What Does -i Equal Anyway?

- Sanding: Start with 200 grit and work your way up to 2000 grit wet-sanding. It's tedious. It's messy. But it’s the only way to get that satin finish.

- Vapor Polishing: If you’re using ABS (which is tricky for frames but doable), an acetone vapor bath will melt the outer layer into a glass-like shine.

- Tumbling: Serious makers use a vibratory tumbler with ceramic media for 24-48 hours. This mimics the industrial process used for high-end acetate frames.

- Dyeing: If you print in natural white Nylon, you can use Rit Dye (the synthetic version) to color your frames any shade you want. It’s not a coating; it soaks into the plastic, so it won't chip off.

Practical Steps to Get Started Tonight

If you’re ready to ditch the optical shop and start making your own 3D printable glasses frames, don't start by trying to design from scratch. That's a rabbit hole that involves complex splines and ergonomic math.

First, go to a site like Printables and search for "glasses frames." Look for a model that has a lot of "makes" (user-uploaded photos). This proves the geometry actually works. Print a test version in cheap PLA just to check the scale against your face. Use a mirror. Check the temple length. Does it reach your ear?

Once the scale is right, switch to PETG or Nylon for the final version. If you don't have a printer, use a service like Shapeways or Xometry to have them printed in "Versatile Plastic" (which is just SLS Nylon). It’ll cost you about $30, and the quality will be indistinguishable from a professional product.

Download a digital caliper app or buy a cheap physical one. You'll need it to measure your Pupil Distance (PD). This is the most important number for your lenses. If your PD is 64mm, the center of your printed lens holes needs to align perfectly with that.

Stop thinking of your glasses as something you have to buy and start thinking of them as something you own. The technology is here, the materials are cheap, and the monopoly of the big eyewear brands is finally starting to crack.

Next Steps for Success:

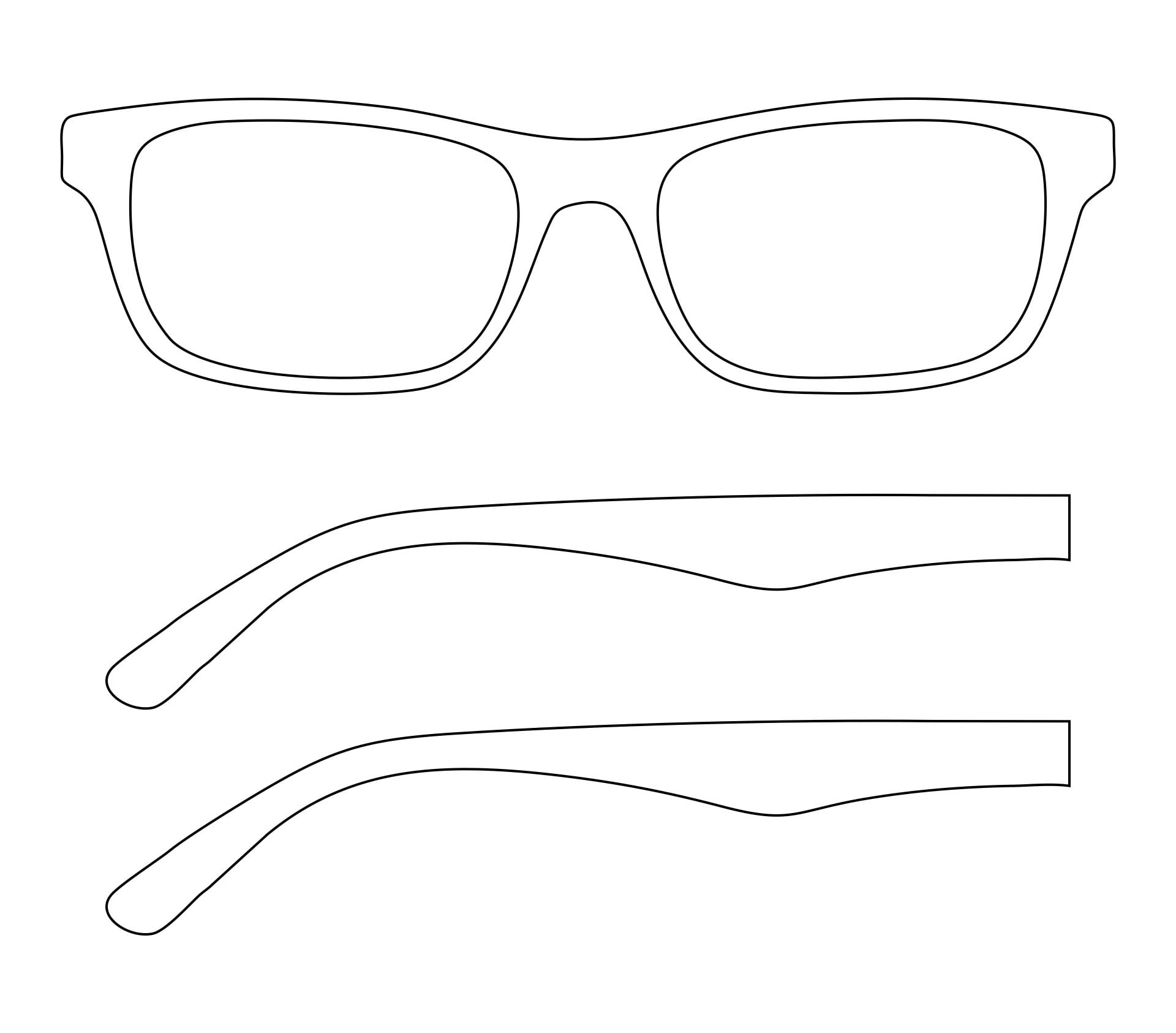

- Measure your current frames: Use calipers to find your bridge width, lens width, and temple length (usually printed on the inside of the arm, e.g., 52-18-145).

- Audit your printer: Ensure your cooling fans are optimized for PETG to prevent "stringing" inside the lens grooves, which can prevent a flush fit.

- Order hardware: Pick up a kit of M1.4 stainless steel screws and compatible hinges before you finish your print, so you aren't tempted to use glue.