You probably think the answer is simple. Henry Bessemer, right? It’s in the name. But history is messy. If you dig into the archives of the 1850s, you’ll find a story of overlapping patents, a bankrupt American ironmaster, and a lucky discovery involving a blast of cold air that shouldn't have worked.

Basically, the Bessemer process changed everything. Before it, steel was a luxury. It was expensive. It was for swords and high-end tools. Then, suddenly, we had skyscrapers and railroads. But the question of who invented the Bessemer steel process isn't answered by a single name on a patent. It’s actually a story of two men, three continents, and a whole lot of legal drama.

The Englishman Who Got the Fame

Henry Bessemer was a serial inventor. He wasn't even a "steel guy" by trade. He had already made a fortune by figuring out how to make gold paint cheaper. By the mid-1850s, he was looking for a better way to make cannons for the Crimean War. The iron of the time was too brittle; it kept exploding. He needed something stronger.

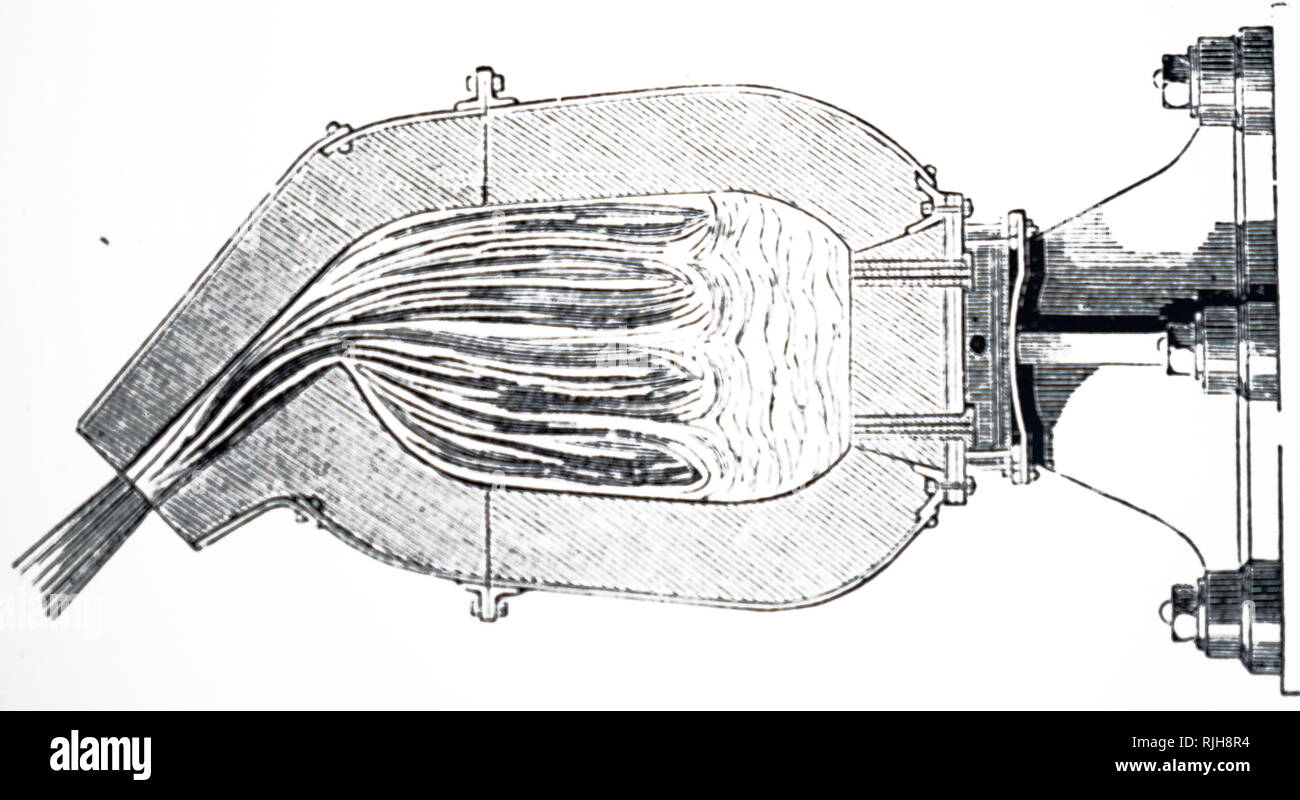

Bessemer’s "aha!" moment was counterintuitive. He realized that blowing cold air through molten pig iron didn't cool it down. It actually made it hotter. Why? Because the oxygen in the air reacted with the carbon impurities in the iron. This combustion created its own heat. It burnt off the carbon and turned iron into steel in about twenty minutes.

Before this, the "puddling" process took days. It was backbreaking work. Bessemer’s method was fast, cheap, and massive. He patented it in 1856. He became a knight. He became incredibly wealthy. Honestly, he’s the textbook definition of a Victorian success story.

The American Who Got Forgotten

While Bessemer was tinkering in London, an American named William Kelly was doing the exact same thing in Kentucky. This is where it gets tricky. Kelly was an ironmaster who noticed as early as 1847 that air could refine iron. He called it "pneumatic steel making."

📖 Related: Dyson V8 Absolute Explained: Why People Still Buy This "Old" Vacuum in 2026

Kelly’s problem was his customers. They didn't trust his "air-boiling" method. They thought he was crazy for trying to use cold air to heat up metal. He actually had to hide his experiments for a while because his father-in-law threatened to cut off his funding if he didn't stop playing with "voodoo" science.

When Bessemer filed his US patent in 1856, Kelly heard about it and immediately filed a "priority of invention" claim. The US Patent Office actually sided with Kelly! They ruled that Kelly had been working on the process years before Bessemer. For a brief moment in history, it was the "Kelly Process."

But Kelly went bankrupt in the Panic of 1857. Bessemer had the capital, the refined machinery, and the global reach. Eventually, the two interests merged, but Bessemer’s name stayed on the door. It’s a classic case of the person who commercializes the invention being the one who gets the credit.

The Missing Ingredient: Robert Mushet

Even with Bessemer's air blast and Kelly's priority, the steel they produced was often brittle. It had too much oxygen left in it. It was kinda useless for anything high-stress.

Enter Robert Forester Mushet. He’s the third, often ignored player in this drama. He discovered that adding a specific alloy called spiegeleisen (a mix of iron, manganese, and carbon) at the very end of the process fixed everything. It removed the excess oxygen and added just enough carbon back in to make the steel tough.

👉 See also: Uncle Bob Clean Architecture: Why Your Project Is Probably a Mess (And How to Fix It)

Bessemer actually let Mushet’s patent lapse and then used the technique. Later, feeling a bit guilty (or perhaps fearing a massive lawsuit), Bessemer paid Mushet an annual pension. Without Mushet’s manganese trick, the Bessemer process would have been a scientific curiosity rather than an industrial revolution.

Why This Debate Still Matters

The Bessemer process didn't just make metal; it built the modern world. Look at any city skyline. You see steel. Think about the 19th-century railroad expansion that linked the American West to the East. That was Bessemer steel.

- Cost reduction: The price of steel dropped from £40 per ton to about £6 or £7 almost overnight.

- Scale: We went from making steel in small crucibles to giant 20-ton converters.

- Urbanization: Cheap steel allowed for the creation of the I-beam, which meant buildings could grow up instead of out.

If we only credit Bessemer, we miss the collaborative, often competitive nature of technology. It wasn't a "lone genius" moment. It was a messy, multi-decade struggle between an English entrepreneur, a Kentucky ironman, and a Scottish metallurgist.

Common Misconceptions About the Invention

People often think Bessemer invented steel. He didn't. Steel had been around for centuries—Damascus steel, anyone? What he invented was a process for mass production.

Another big mistake is thinking the Bessemer process is what we use today. We don't. By the early 1900s, the Open Hearth process started taking over because it allowed for better quality control and used scrap metal. Today, most steel is made using Basic Oxygen Steelmaking (BOS) or Electric Arc Furnaces (EAF). The Bessemer converter is mostly a museum piece now.

✨ Don't miss: Lake House Computer Password: Why Your Vacation Rental Security is Probably Broken

What You Should Take Away

If you're researching who invented the Bessemer steel process, you have to look at it as a "simultaneous discovery."

- Henry Bessemer provided the engineering and the global business model.

- William Kelly likely had the idea first but lacked the resources to scale.

- Robert Mushet provided the chemical "secret sauce" that made the metal actually usable.

This is how innovation usually works. It’s rarely one person in a vacuum. It’s a series of improvements, legal battles, and lucky breaks.

Actionable Insights for History and Tech Buffs:

- Audit your sources: When reading industrial history, check if the author is British or American. You’ll notice a huge bias toward either Bessemer or Kelly depending on which side of the pond the book was printed.

- Study "Simultaneous Discovery": Look into the "Multiple Discovery" theory. It happens in science all the time—like Calculus (Newton vs. Leibniz) or the Telephone (Bell vs. Gray).

- Visit a museum: If you want to see a real Bessemer converter, the Kelham Island Museum in Sheffield has one of the last remaining examples. Seeing it in person makes you realize just how violent and impressive the process actually was.

- Apply the lesson: Remember that having a great idea (Kelly) isn't enough; you need the refinement (Mushet) and the business execution (Bessemer) to change the world.

The Bessemer process eventually died out because it couldn't remove phosphorus from certain types of iron ore, a problem solved later by Sidney Gilchrist Thomas. But for fifty years, it was the king of industry. It was the spark that lit the fuse of the 20th century. Even if the naming rights are a bit unfair, the impact is undeniable.