You walk into a room and your eyes go straight up. That’s the magic of volume. But here is the thing: that airy, "wow-factor" look doesn't just happen because a builder felt inspired. It lives and dies by the engineering of vaulted ceiling roof trusses. Most people think you just chop out the attic floor and call it a day. Do that, and your walls will literally start bowing outward until the whole structure fails. Trust me, I've seen the repair bills on DIY "open concept" disasters, and they aren't pretty.

The Physics of Why Your Roof Doesn't Collapse

Standard roofs usually rely on a flat bottom chord to tie the walls together. Think of it like a giant triangle where the bottom bar keeps the two sides from sliding apart. When you want a vaulted look, you're essentially messing with that triangle.

The most common way to achieve this safely is through a scissor truss. These are fascinating. Instead of a flat bottom, the lower chords curve upward to a peak. It looks like a pair of open scissors, hence the name. This design allows for a sloped ceiling inside while maintaining the structural integrity needed to keep the weight of the shingles and snow from pushing your exterior walls into the neighbor's yard.

But there’s a trade-off. You won't get a "cathedral" peak that matches the outside roof pitch exactly. Usually, the interior slope is about half of the exterior pitch. If your roof is an 8/12 pitch, your inside vault is probably going to be a 4/12. It’s a compromise. Physics is a stubborn roommate.

Scissor Trusses vs. Parallel Chord Trusses

If you want that ultra-modern look—the kind you see in those $5 million mountain retreats in Aspen—you’re likely looking at parallel chord trusses.

These are different. They consist of a top and bottom chord that run exactly parallel to each other. It creates a "slanted" ceiling rather than a peaked one. They are great for shed roofs or mono-pitch designs. The depth of the truss itself allows for massive amounts of insulation. This is a huge deal because heating a room with 20-foot ceilings is a nightmare if you don't have the R-value to back it up.

I talked to a structural engineer in Oregon last year who mentioned that people often underestimate "deflection." When you use long-span vaulted ceiling roof trusses, the wood actually bends slightly under heavy loads. If you've got drywall tight against those trusses without a proper furrowing strip or resilient channel, your beautiful ceiling is going to look like a map of the Grand Canyon within two winters. Cracks everywhere.

📖 Related: Little Taste of Britain Layton UT: Why This Shop is Still the Real Deal

The Insulation Nightmare Nobody Mentions

Building a vault is easy. Living in one is the hard part.

When you have a standard attic, you have a massive "buffer zone" of air. In a vaulted setup, your ceiling is basically right against the roof. You need to pack a lot of insulation into a very small vertical space.

- Closed-cell spray foam is often the gold standard here. It provides a high R-value per inch and acts as a vapor barrier.

- Mineral wool batts are another option, though you need deeper truss members to get the same performance.

- Baffles are non-negotiable if you’re using traditional fiberglass. You must have airflow from the soffit to the ridge vent. If you block that air path, you’ll get ice dams. Ice dams lead to rot. Rot leads to a very expensive phone call to a contractor.

Site-Built vs. Prefabricated

Can you build these on-site? Sure. Should you? Probably not.

Most modern homes use "pre-engineered" trusses manufactured in a factory. Companies like Alpine or MiTek use specialized software to calculate the exact load-bearing requirements for your specific zip code. They account for wind speeds, snow loads, and even the weight of that massive iron chandelier you're planning to hang in the center.

When you buy prefab vaulted ceiling roof trusses, they arrive on a flatbed, usually with a stamped engineer's seal. This makes the building inspector happy. If you try to stick-frame a vaulted ceiling on-site, be prepared for a long, painful conversation with the local building department about structural calculations. It’s almost always cheaper and faster to go prefab, even with the crane rental costs.

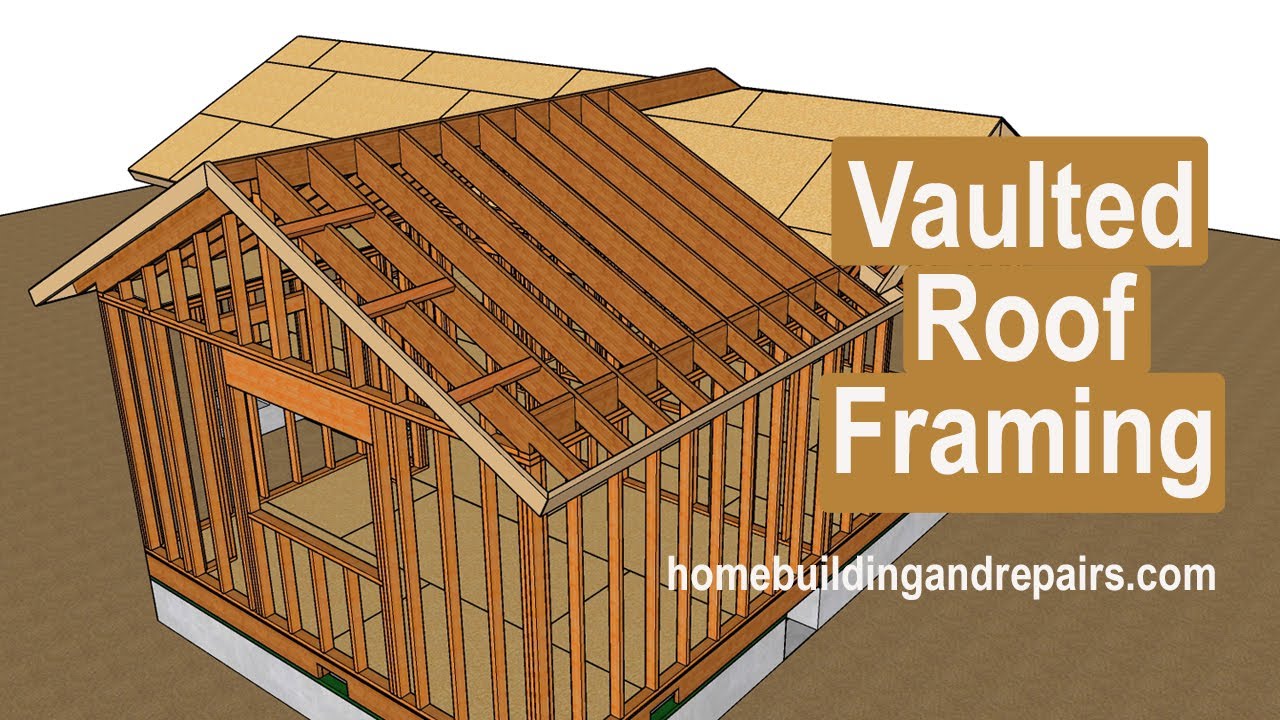

[Image showing the difference between a standard King Post truss and a Scissor truss]

Cost Realities: Is the "Volume" Worth It?

Honestly, expect to pay about 20% to 30% more for your roof package if you go with vaulted trusses over standard ones.

It’s not just the wood. It’s the complexity. It’s the extra drywall finishing work. It’s the fact that your painter now needs a specialized scaffolding rig instead of a six-foot ladder.

Lighting is another hidden cost. You can’t just pop in standard recessed "can" lights. You need "slope-rated" housings. If you don't buy the right ones, the light will point at the wall at a weird angle instead of straight down at your coffee table. It looks amateur.

Common Misconceptions About Cathedral Ceilings

People use the terms "vaulted" and "cathedral" interchangeably. They aren't the same.

A cathedral ceiling follows the exact pitch of the roof. To do this, you usually can't use trusses at all; you have to use a massive ridge beam (often an LVL or steel) and rafters. It’s way more expensive.

📖 Related: Hiền Thanh Restaurant Menu: What to Order Before Everyone Else Finds Out

Vaulted ceiling roof trusses are the "middle ground." They give you the feeling of a cathedral ceiling without the massive structural steel price tag. They are a clever trick of engineering.

How to Plan Your Project

If you are in the planning stages, don't just tell your architect "I want it open." You need to specify the height of the "heel."

The "heel height" is where the truss sits on the wall. A "raised heel" truss allows for more insulation at the edge of the house. In colder climates, this is mandatory by code in many places now. If you have a shallow heel, your insulation gets squished at the edges, creating a cold spot where mold loves to grow.

- Check your local snow load requirements. A truss designed for Georgia will fail in Minnesota.

- Plan your HVAC. Heat rises. If you don't have a ceiling fan or a return vent high up on the wall, your feet will be freezing while the top of the room is 80 degrees.

- Think about acoustics. Big, open ceilings bounce sound like crazy. You might need to invest in some "soft" finishes—rugs, heavy curtains, or acoustic panels—to keep the room from sounding like a gymnasium.

Final Practical Steps for Success

If you’re pulling the trigger on a renovation or a new build, your first move isn't Pinterest. It’s a structural assessment.

- Step 1: Hire a structural engineer if you are retrofitting. Do not trust a general contractor who says "it looks fine" without a stamped drawing.

- Step 2: Order your trusses at least 8-12 weeks in advance. Lead times in the industry have been volatile lately.

- Step 3: Confirm the "clear span." If your room is wider than 30 feet, you might need internal load-bearing walls or specialized heavy-duty trusses.

- Step 4: Inspect the trusses upon delivery. Look for "plate migration"—where the metal connector plates have pulled away from the wood during shipping. If they are loose, reject the truss.

Building up instead of out is one of the best ways to add value to a home. It makes a small footprint feel massive. Just make sure the "bones" overhead are up to the task.