You’ve probably driven past it if you've ever hauled boat trailers down to Choke Canyon or made the trek from San Antonio to Corpus Christi. It’s that massive, gleaming labyrinth of steel and steam rising out of the brush land. Most folks just see it as a landmark on Highway 281. But the Valero Three Rivers Refinery is actually one of the most interesting pieces of the Texas energy puzzle, and honestly, it doesn't get the credit it deserves for keeping the regional economy from stalling out.

It’s big. It’s loud. It’s essential.

The facility sits right in Live Oak County, basically the heart of the Eagle Ford Shale. That’s not a coincidence. While other refineries are struggling to adapt to changing crude types, Three Rivers is sitting pretty right on top of the source.

Why the Valero Three Rivers Refinery is Different

Refineries aren't all built the same. Some are "complex," meaning they can take the heavy, sour sludge from overseas and turn it into gas. Others are "simple." Three Rivers is a bit of a hybrid in terms of its strategic importance. It’s a high-complexity facility, but its real superpower is its location.

Because it’s located in the middle of the Eagle Ford, it can take "advantageous" feedstocks. In plain English? It gets the good stuff cheap and fast.

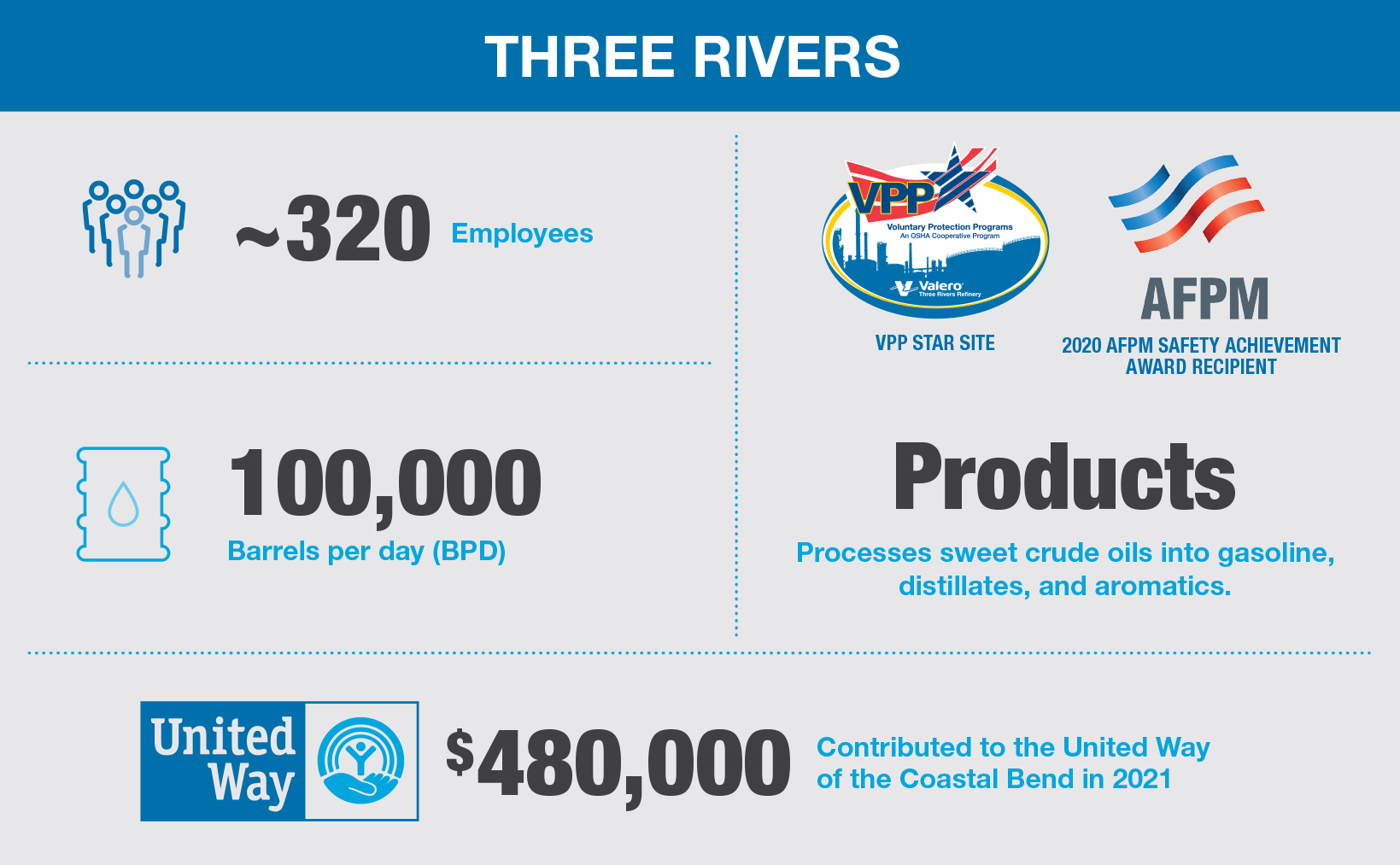

The refinery has a throughput capacity of roughly 100,000 barrels per day. To a layman, that sounds like a lot. To an industry vet, it’s a "mid-sized" plant. But don't let the size fool you. It’s incredibly efficient. It’s one of the reasons Valero—the company based out of San Antonio—remains a dominant force. They aren't just shipping oil across the world; they are refining it right where it comes out of the ground.

Most people think refineries just make "gas." Wrong. Three Rivers is a major producer of ultra-low-sulfur diesel and jet fuel. If you've flown out of a South Texas airport recently, there’s a decent chance the fuel keeping that plane in the air came from right here. They also produce aromatics and other petrochemical feedstocks.

The Logistics Game: Pipelines and Trucks

You can't talk about Three Rivers without talking about how the oil actually gets there. It’s a logistical nightmare that Valero turned into a science.

👉 See also: Why 425 Market Street San Francisco California 94105 Stays Relevant in a Remote World

The refinery is tied into an extensive network of pipelines. We're talking about the NuStar systems and Valero’s own proprietary lines. But here’s the kicker: because it’s so close to the production wells, the "transportation discount" is massive.

- Crude In: Mostly light sweet crude from the surrounding Eagle Ford.

- Products Out: Finished gasoline and diesel.

- Destination: San Antonio, Austin, and the Rio Grande Valley.

Think about that. It’s a closed loop. The oil is pulled from Texas soil, refined in a Texas town, and burned in Texas cars. That kind of vertical integration is what keeps Valero’s margins higher than many of its Gulf Coast competitors who have to wait for tankers to arrive from the Middle East or South America.

Safety, Flaring, and the "Big Smoke" Myth

Let’s be real for a second. People get nervous when they see a flare stack lit up at night. It looks like a giant torch against the South Texas sky.

Flaring is actually a safety mechanism.

When there is a pressure imbalance or a piece of equipment needs to be taken offline for maintenance, the gases have to go somewhere. Burning them off is the safest way to prevent a catastrophic buildup. The Valero Three Rivers Refinery is subject to some of the strictest EPA and TCEQ (Texas Commission on Environmental Quality) standards in the country.

Does that mean it’s perfect? No. No heavy industrial site is. There have been "upsets" and accidental releases in the past—every refinery has them. But if you look at the data from the last decade, Valero has poured millions into emissions reduction technology. They’ve installed advanced leak detection systems and "scrubbers" that catch particulates before they hit the atmosphere.

Interestingly, the refinery is one of the largest employers in Live Oak County. We are talking hundreds of high-paying jobs. If that plant shuts down for a week, the local economy feels it immediately. The grocery stores, the hardware shops, the local diners—they all rely on the "turnaround" crews and the full-time staff who call Three Rivers home.

✨ Don't miss: Is Today a Holiday for the Stock Market? What You Need to Know Before the Opening Bell

The Eagle Ford Connection: A Symbiotic Relationship

Back in 2008, when the fracking boom started, Three Rivers was positioned perfectly. Before the boom, it was a solid facility. After the boom? It became a gold mine.

The crude coming out of the Eagle Ford is "light and sweet." This means it has low sulfur content and is easier to process into high-value products like premium gasoline. The Valero Three Rivers Refinery was essentially "re-tooled" over the years to maximize this specific type of oil.

It’s a match made in heaven. Or at least in the Permian Basin’s neighbor.

What Actually Happens Inside?

If you were to walk through the gates (which you can't, for obvious security reasons), you’d see a few key units that do the heavy lifting:

- The Atmospheric Distillation Unit: This is the first stop. It heats the crude oil until it boils and separates into different components based on their boiling points.

- The Hydrocracker: This uses heat, pressure, and hydrogen to "crack" heavy oil molecules into lighter, more valuable ones like diesel and jet fuel.

- The Reformer: This is where they take low-octane naphtha and turn it into high-octane components for premium gasoline.

It’s basically a giant, high-pressure kitchen.

Economic Impact and the "Turnaround" Season

Every few years, the refinery goes through what’s called a "turnaround." This is basically a massive spring cleaning where they shut down parts of the plant to inspect, repair, and replace equipment.

For the town of Three Rivers, this is like the Super Bowl.

🔗 Read more: Olin Corporation Stock Price: What Most People Get Wrong

Thousands of specialized contractors flood the area. Hotels are booked solid for months. Every RV park within a fifty-mile radius is full. It’s a massive injection of cash. But it’s also a time of high tension. The work is dangerous, the hours are long (12-hour shifts are the norm), and the pressure to get the plant back "on-stream" is immense.

Valero has a reputation for being one of the better operators in terms of safety during these windows, but the sheer scale of the labor involved is staggering.

Looking Forward: The Future of Refining in South Texas

Is the refinery going away? Probably not anytime soon. Even with the push toward electric vehicles, the demand for diesel (for trucking) and jet fuel (for aviation) isn't disappearing.

In fact, Three Rivers is likely to become more important as other, older refineries on the coast deal with rising sea levels and hurricane threats. Being inland gives Three Rivers a massive advantage. It can keep running when a Category 4 storm is hammering Houston or Corpus Christi.

Valero has also been leaning into "renewable diesel" and other carbon-capture initiatives. While Three Rivers is still a traditional petroleum refinery, the technology being tested there often paves the way for cleaner operations across the board.

Practical Insights for the Community and Workers

If you're looking to work at the Valero Three Rivers Refinery, or if you're a local resident concerned about the operations, here are the ground truths:

- For Job Seekers: Don't just apply online. Valero prizes technical certifications and military experience. Most of the "entry-level" operators have degrees in Process Technology (P-Tech). If you want in, get that degree from a community college like Del Mar or Alamo Colleges.

- For Residents: Stay informed through the TCEQ's Central Registry. You can look up the refinery’s air quality permits and any reported violations. Transparency is your friend.

- For Investors: Keep an eye on the "crack spread"—the difference between the price of crude oil and the price of the products. When that spread is wide, Three Rivers is printing money for Valero.

The Valero Three Rivers Refinery isn't just a bunch of pipes. It’s a critical organ in the body of the Texas economy. It’s complex, sometimes controversial, but ultimately the reason you can fill up your tank and head to the coast without a second thought.

To stay updated on local impact or potential road closures during major turnarounds, check the Live Oak County Sheriff’s Office social media pages or the Valero corporate newsroom. If you live in the area, make sure you're signed up for local emergency alerts, as the refinery coordinates closely with county officials on safety drills and community notifications. Knowing the difference between a routine "steam blow" and an actual emergency flare-up can save you a lot of unnecessary stress.