You’re sweating. It’s 95 degrees outside, and your vents are blowing something that feels suspiciously like a blow dryer on the "low" setting. You pop the hood, stare at the tangled mess of hoses, and realize you need a car air conditioning diagram just to make sense of the chaos. Most people think their AC creates cold air. It doesn’t. That’s the first thing you have to unlearn if you want to actually fix the thing. Your car’s AC is a heat relocation service. It grabs the heat inside your cabin and dumps it onto the asphalt. Simple, right? Well, the plumbing makes it look like a nightmare.

If you’ve ever looked at a factory service manual from a brand like Toyota or Ford, the diagrams look like a plate of spaghetti. You’ve got high-pressure lines, low-pressure lines, sensors, and a compressor that’s probably buried under an alternator. But every single system, whether it’s in a 1994 Civic or a brand-new F-150, follows the same basic loop.

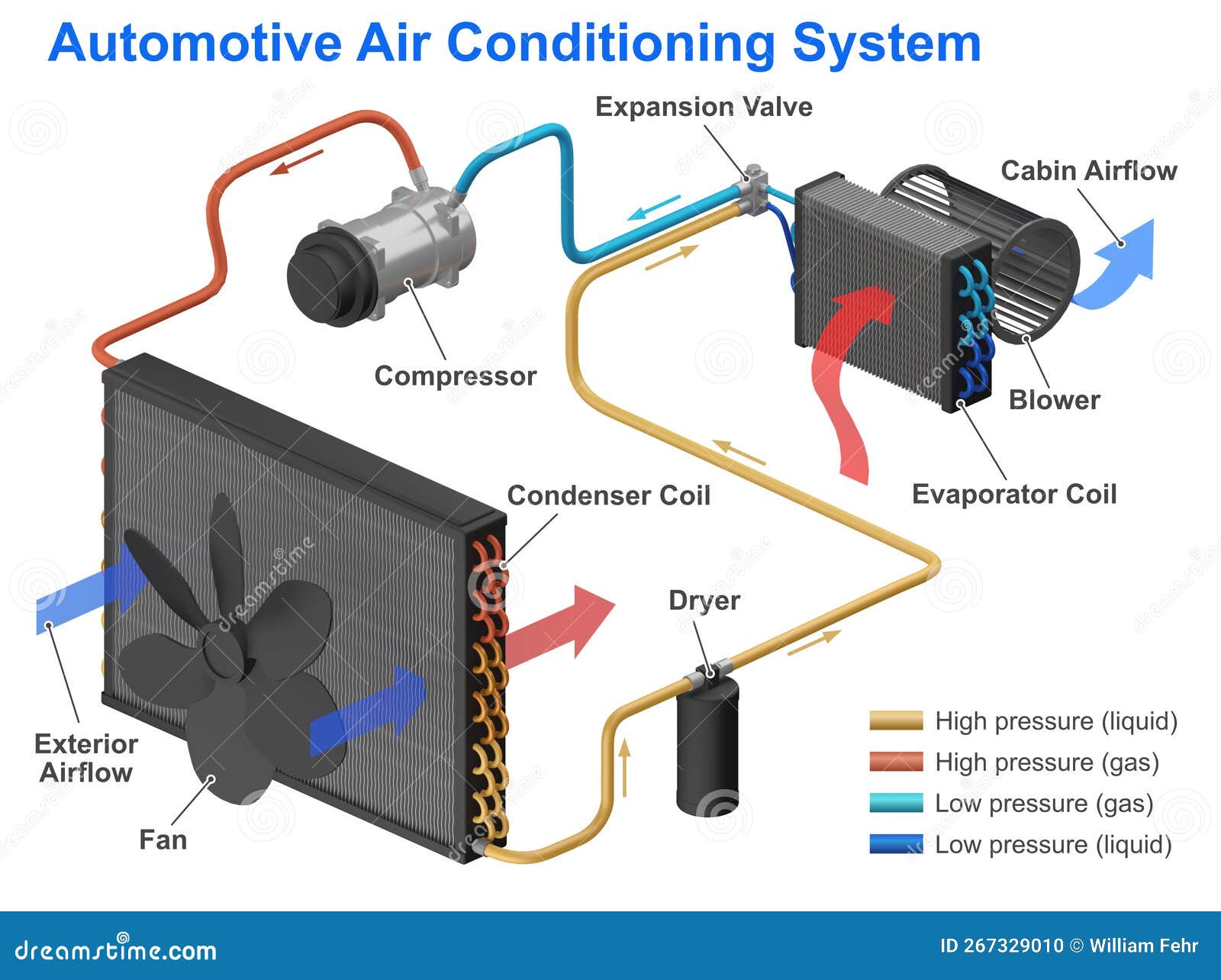

The Loop: Why Your Car Air Conditioning Diagram Is Actually a Circle

Everything starts at the compressor. Think of this as the heart. If the compressor dies, the whole system is just dead weight. It’s a pump driven by your engine’s serpentine belt. When you hit that AC button, an electromagnetic clutch snaps shut, and the compressor starts squeezing refrigerant gas. This is where the physics gets weird. When you compress a gas, it gets hot. Like, really hot. We’re talking $200^{\circ}F$ territory.

This high-pressure, scorching-hot gas travels to the condenser. If you look at a car air conditioning diagram, you’ll see the condenser sitting right in front of your radiator. It looks like a miniature version of it. Its job is to let the outside air move over those fins and soak up the heat. As the gas cools down under all that pressure, it turns into a liquid.

The High Side vs. The Low Side

This is the part that trips up DIYers. Your AC system is split into two halves.

The "High Side" is everything from the compressor outlet to the expansion valve. It’s dangerous territory. Pressures here can top 300 PSI on a hot day. You’ll notice in most diagrams these lines are colored red or drawn with thicker borders.

Then you have the "Low Side." This is the "cold" part. It’s where the magic happens. After the liquid refrigerant leaves the condenser, it passes through a tiny restriction—usually an expansion valve or an orifice tube. It’s basically a spray nozzle.

Imagine spraying an aerosol can of hairspray. The nozzle gets cold, right? That’s exactly what’s happening in your dashboard. The high-pressure liquid turns into a low-pressure mist as it enters the evaporator.

The Evaporator: Where the Chill Happens

This is the component most people never see because it’s buried deep inside the HVAC box under your dash. A car air conditioning diagram shows the evaporator as the final stop before the air hits your face. Your cabin fan blows warm air across these freezing cold coils. The refrigerant inside the coils absorbs the heat from your cabin air, causing the refrigerant to boil and turn back into a gas.

Yes, it boils at temperatures that would freeze water.

This is also why you see a puddle of water under your car on humid days. The evaporator is so cold that moisture from the air condenses on the outside of the coils and drips out of a drain tube. If that tube gets clogged, you end up with wet carpets and a smell like a gym locker.

👉 See also: How to Download an Instagram Image Without Ruining the Quality

Real World Failure Points

Let’s talk about why your diagram doesn't always match reality.

In a perfect world, the refrigerant stays in the loop forever. In the real world, seals dry out. Stones fly through your grille and puncture the condenser.

I’ve seen dozens of cases where people try to "recharge" their system using those cans from the auto parts store, thinking they’re fixing a leak. Usually, they just overcharge it. If you put too much refrigerant in, the compressor can’t do its job, and the high-pressure switch will kill the power to the clutch to prevent an explosion.

- The Accumulator/Drier: Often overlooked. It’s a metal cylinder that acts as a filter and moisture trap. If you ever open your AC system to replace a part, you have to replace this too. It’s filled with desiccant (those "do not eat" silica packets). Once it’s exposed to open air for more than a few minutes, it’s useless.

- The Orifice Tube: These are notorious for getting clogged with "black death"—a slang term mechanics use for the debris created when a compressor starts grinding itself to pieces. If your car air conditioning diagram shows an orifice tube instead of an expansion valve, be ready for a messy repair if the compressor fails.

Modern Variations: R134a vs. R1234yf

You can’t talk about AC diagrams without talking about what’s actually inside the pipes. For decades, R134a was the king. It was cheap and worked well. But, it’s a greenhouse gas.

Enter R1234yf.

Most cars built after 2018 use this stuff. It’s better for the planet, but it’s incredibly expensive and, fun fact, slightly flammable. If you’re looking at a car air conditioning diagram for a newer Tesla or a BMW, the components look the same, but the service ports are different sizes to prevent you from mixing the gases.

Never try to bypass this. Mixing refrigerants creates a chemical sludge that will ruin every component in the loop. Honestly, it’s the fastest way to turn a $200 repair into a $3,000 nightmare.

The Electrical Layer

The mechanical diagram is only half the story. The computer—usually the PCM (Powertrain Control Module) or a dedicated HVAC controller—actually runs the show.

It monitors:

✨ Don't miss: Where the Space Shuttle Challenger Debris is Now and Why It’s Still Surfacing

- Ambient Air Temperature: Is it too cold outside to run the AC?

- High/Low Pressure Switches: Is there enough gas? Is there too much?

- Evaporator Temperature Sensor: Is the coil about to freeze into a block of ice?

If any of these sensors send a "bad" signal, the computer won't engage the compressor. You could have a perfectly filled system with a brand-new compressor, but if a $15 plastic sensor thinks the car is overheating, you’re going to be sweating.

Troubleshooting Using Your Car Air Conditioning Diagram

When you're staring at the diagram, start with the "Touch Test." It's the most primitive but effective way to see where the system is failing.

With the car running and the AC on max, carefully feel the two lines coming out of the firewall (the metal wall between the engine and the cabin).

One should be ice cold and probably covered in condensation. This is the low-pressure suction line heading back to the compressor. The other should be warm or hot. This is the high-pressure liquid line.

If they both feel the same temperature? Your compressor isn't engaging or you've lost your charge. If the "cold" line is only "kinda" cool, you’re likely low on refrigerant.

Why Diagrams Matter for Leaks

Most leaks happen at the "O-rings"—the little rubber circles that seal the connections between hoses and components. A car air conditioning diagram will show you exactly where these joints are. There’s usually one at the compressor, two at the condenser, and two at the firewall.

If you see oily dirt buildup at any of these junctions, that’s your leak. Refrigerant is mixed with a specific type of oil (PAG oil), and when the gas leaks out, the oil leaves a "stain" that attracts dust.

Actionable Steps for the Home Mechanic

- Identify your refrigerant. Look for the sticker under the hood. It will tell you if you have R134a or R1234yf and exactly how many ounces the system holds. Don't guess.

- Inspect the Condenser. Take a flashlight and look through your front bumper. If the fins are flattened by car washes or filled with dead dragonflies, your AC won't work well. Gently straighten the fins with a "fin comb" or a small screwdriver.

- Check the Cabin Air Filter. This is the #1 reason for "weak" airflow. If the filter is clogged, air can't pass over the evaporator. It doesn't matter how cold the refrigerant is if the air can't get to it.

- Listen for the "Click." Have someone turn the AC on while you watch the compressor. You should hear a loud clack and see the center part of the pulley start spinning. If it doesn't spin, check your fuses and the AC relay first.

- Use a Manifold Gauge Set. Don't rely on the single-gauge cans. You need to see both the High Side and Low Side pressures simultaneously to understand what the car air conditioning diagram is actually telling you about the system's health.

Maintaining your AC isn't just about comfort. It's about preventing the system from "slugging"—which is what happens when liquid refrigerant gets back into the compressor and destroys the internal pistons. Keep the system clean, keep the airflow unobstructed, and always consult the specific diagram for your year and model before you start turning wrenches. Generally, if the system is totally empty, you need a vacuum pump to pull all the air and moisture out before adding new gas, otherwise, you're just inviting corrosion to live inside your lines.

Properly diagnosing the system requires patience. Take it slow, follow the lines from the compressor out to the condenser and back through the evaporator, and you'll find that the "black box" of automotive cooling isn't so mysterious after all.