You’ve probably seen one of those looping GIFs. A piston goes up, a spark fires, and smoke puffs out the side while fresh air swirls in from the bottom. It looks like a toy. Compared to the complex valvetrain of a modern car engine, a two stroke engine animation makes internal combustion look like child's play. But don't let that simplicity fool you. Honestly, the engineering required to make an engine run without traditional intake or exhaust valves is nothing short of a mechanical miracle.

Most people think these engines are just for chainsaws or cheap dirt bikes. That’s a mistake. While the world is moving toward electrification and high-tech four-strokes, the "stroker" remains a masterclass in power-to-weight ratios. When you watch a high-quality animation of this process, you aren't just looking at moving parts; you're watching a delicate dance of fluid dynamics and pressure waves that happens thousands of times per minute.

What's Actually Happening in That Animation?

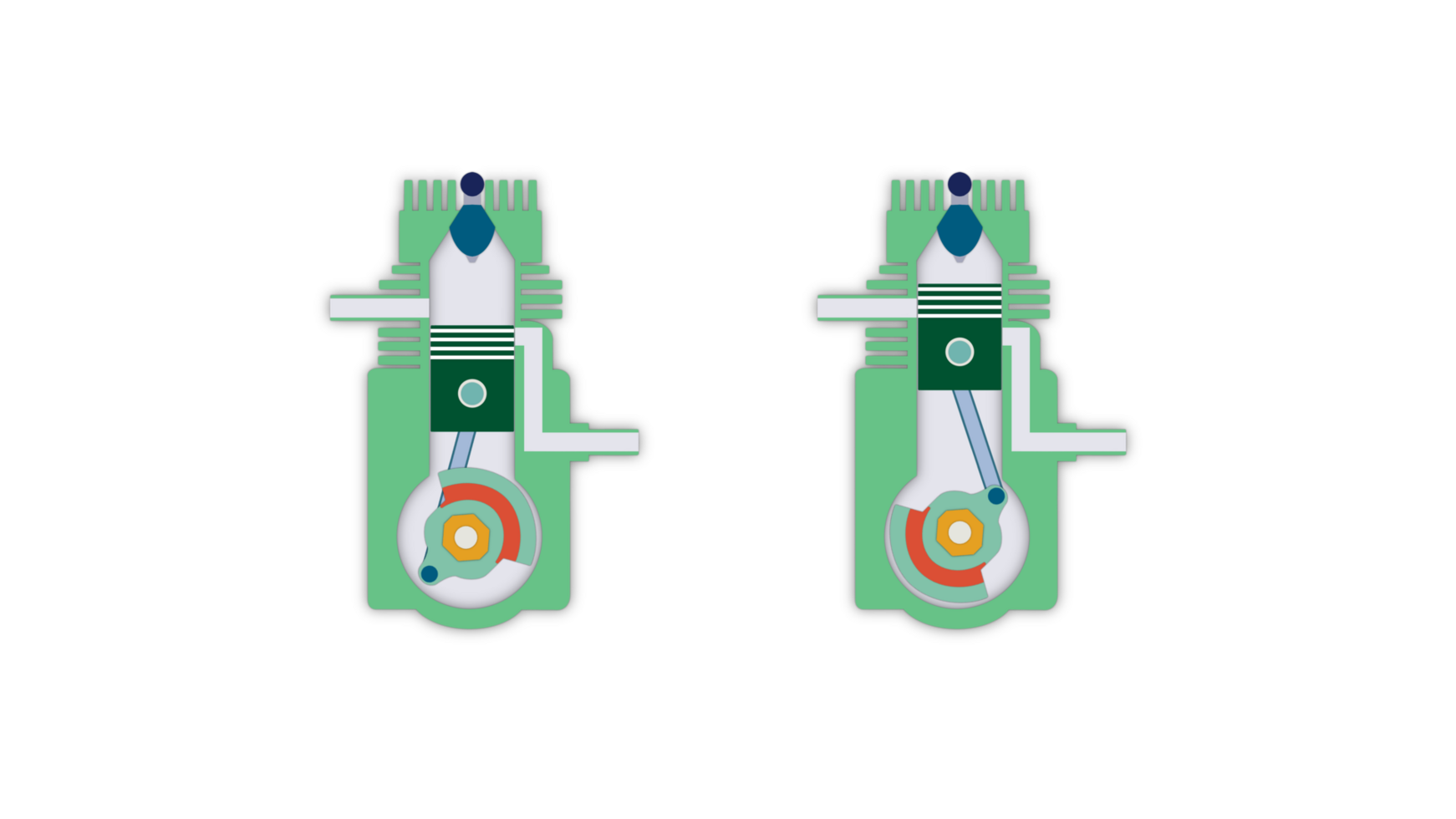

If you look closely at a two stroke engine animation, the first thing you notice is what’s missing. There are no camshafts. No rockers. No heavy valves clicking open and shut. Instead, the piston itself acts as the valve. As it moves up and down, it covers and uncovers holes in the cylinder wall called ports.

It's a two-stage process.

First, there’s the Upward Stroke. The piston moves toward the spark plug, compressing the air-fuel mixture in the combustion chamber. Simultaneously, it creates a vacuum in the crankcase below, sucking in fresh fuel and air through a reed valve. Then comes the Downward Stroke. The spark fires, the explosion pushes the piston down, and the exhaust gases scream out of the exhaust port. At the same time, the downward movement of the piston pushes that fresh mixture from the crankcase up through "transfer ports" into the cylinder.

👉 See also: Amazon Prime in India: What Most People Get Wrong About the 1499 Price Tag

It happens fast.

Really fast. A 250cc motocross bike might idle at 1,500 RPM and scream up to 9,000 RPM. That means the entire cycle—intake, compression, power, and exhaust—is completing 150 times every single second. When you see a slow-motion two stroke engine animation, it’s easy to forget that in the real world, those metal parts are a blurring mess of heat and vibration.

The Scavenging Problem (And Why Animations Often Lie)

Here is where it gets tricky. In a perfect world, the fresh air-fuel mixture would push all the burnt exhaust out and stay perfectly inside the cylinder. Engineers call this "scavenging." In reality, it's messy. Some of the fresh fuel inevitably leaks out of the exhaust port before it can be burned. This is why two-strokes historically smelled like a lawnmower and produced high emissions.

If you watch a basic two stroke engine animation, it usually shows the blue "fresh air" and gray "exhaust" staying perfectly separate. That’s a lie. In a real engine, they mix. This is why modern designs, like KTM’s Transfer Port Injection (TPI) or Rotax’s E-TEC systems, are so revolutionary. They use sensors and precise timing to inject fuel only after the exhaust port is closed, or at very specific intervals, to keep the engine clean.

The Expansion Chamber: The "Invisible" Component

You cannot talk about how these engines work without mentioning the pipe. You know that fat, bulbous exhaust pipe on a dirt bike? That isn't just for looks or noise. It’s an essential part of the engine’s "breathing" cycle.

✨ Don't miss: Why You Can't Kindle Unlimited Cancel Subscription on the App—and How to Actually Do It

A high-end two stroke engine animation will often show pressure waves. When the exhaust port opens, a high-pressure pulse shoots into the pipe. The pipe is shaped like a cone, which causes the pulse to expand and then reflect back toward the engine. This reflected "sonic wave" actually pushes the escaping fresh fuel back into the cylinder right before the piston covers the port. It’s basically a turbocharger made of hollow steel and physics. Without that specific pipe shape, a two-stroke loses half its power. It’s a tuned instrument, like a trumpet.

Why We Still Use This "Ancient" Tech

People keep saying the two-stroke is dead. They’ve been saying it since the 70s. Yet, here we are in 2026, and they are still everywhere. Why? Because they are light. A four-stroke engine requires a heavy cylinder head filled with valves, springs, and cams. A two-stroke is basically a hollow tube with a piston in it.

- Power Density: Because they fire every single time the piston goes up (instead of every other time like a car), they can theoretically produce twice the power for the same displacement.

- Simplicity: You can rebuild a top end on a two-stroke in about 45 minutes with basic hand tools.

- Orientation: Since most two-strokes use the crankcase for fuel transfer rather than a pool of oil, they can run upside down. This is why your weed whacker doesn't die when you tilt it.

The Evolution of 2T Visuals

If you are looking for a two stroke engine animation to study, don't just settle for a 2D drawing. Look for 3D CFD (Computational Fluid Dynamics) simulations. These are the "pro" versions of animations. They use color gradients to show temperature changes—moving from cool blue at the intake to a white-hot 2,000°C at the spark.

Researchers at places like the University of Graz or specialists at companies like Yamaha use these animations to see "tumble" and "swirl" patterns. They want to see how the air rotates inside the chamber. If the air doesn't swirl correctly, the fuel won't burn completely, leading to "dead spots" in the powerband.

Common Misconceptions Found in Visuals

A lot of people watch a two stroke engine animation and walk away with the wrong idea about lubrication. They see the piston sliding and think, "Where is the oil?"

In a car, the crankshaft sits in a bath of oil. In a two-stroke, the crankcase is full of air and fuel. This is why you have to mix oil into the gasoline (or use an injection pump). The oil enters the engine as a fine mist, coats the bearings and cylinder walls, and then gets burned up and spat out the tailpipe. It’s a "total loss" system. If the animation doesn't show a slightly oily mist entering the intake, it’s skipping a crucial part of the mechanical reality.

Technical Nuance: The Reed Valve

The unsung hero of the modern two-stroke is the reed valve. It's a small cage with flexible petals (usually carbon fiber or fiberglass) that sits between the carburetor and the engine. In a two stroke engine animation, you’ll see these petals fluttering.

They act as a one-way check valve. When the piston goes up, the vacuum pulls them open. When the piston goes down, the pressure slams them shut so the fuel is forced up into the cylinder instead of back out through the carb. It’s a tiny detail, but if those petals chip or wear out, the engine will never start.

How to Use This Knowledge

If you’re a student, a mechanic, or just a gearhead, don't just watch these animations passively. Use them to diagnose problems.

💡 You might also like: Is ChatGPT Plus for College Students Actually Worth the Monthly Subscription?

- Look at the port timing. If you want more top-end power, you technically want the exhaust port to be "higher" in the cylinder so it stays open longer, though you lose low-end torque.

- Observe the crankcase volume. A smaller crankcase increases "primary compression," which snaps the fuel up into the cylinder faster. This is why racers sometimes "stuff" their cranks to reduce empty space.

- Check the piston skirt. Notice how long the piston is? That’s because it has to be long enough to keep the ports covered when it’s at the top of the stroke. If it's too short, the engine won't run.

Watching a two stroke engine animation is basically a rite of passage for anyone interested in how things work. It’s the bridge between simple machines and high-performance engineering. While the world gets more complicated with hybrids and EVs, there is something deeply satisfying about a machine that only has three main moving parts—piston, rod, and crank—yet can scream like a banshee and propel a vehicle at 100 mph.

To really master this, go find a "cutaway" animation that shows the transfer ports in 3D. Most people forget there are usually 3, 5, or even 7 of these ports surrounding the cylinder. The way they are angled determines how well the engine runs. It's not just about letting air in; it's about aiming it so it doesn't just fly out the exhaust.

Next time you see a puff of blue smoke, you'll know exactly what's happening inside that metal shell. It’s not just "fire and bang." It’s a perfectly timed sequence of pressure waves and mechanical timing that has remained largely unchanged for over a century, simply because it’s hard to beat something so efficient and light.

Next Steps for Deep Learning:

- Search for "Expansion Chamber Wave Animation" to see how sound waves actually "supercharge" the engine.

- Compare a Loop-Scavenged animation vs. a Uniflow-Scavenged animation (used in giant diesel ships) to see the different ways engineers solve the exhaust problem.

- Look up "Direct Injection Two Stroke" to see how companies like Evinrude or BRP made these engines as clean as modern cars.

The tech isn't dead; it's just evolving. Understanding the animation is the first step to respecting the machine.