You're staring at a custom cabinet project. The wood is gorgeous. The joinery is tight. But then you realize the internal geometry is a nightmare because there's absolutely zero clearance on the sides for traditional runners. You've got maybe an eighth of an inch if you're lucky. This is exactly where top mount drawer slides enter the conversation, usually accompanied by a fair bit of grumbling from old-school purists who think everything should be under-mounted or side-mounted with ball bearings.

Honestly, top mounting is weird.

It’s the black sheep of the hardware world. While 90% of the industry obsesses over side-mounts or those fancy Blum Tandem hidden runners, top-mounted hardware occupies a very specific, almost niche corner of the cabinetry universe. Most people get them wrong because they try to use them like standard slides. You can't do that. If you try to hang a heavy pot-and-pan drawer from the top using a slide designed for light-duty applications, the whole thing is going to rack, bind, and eventually rip the screws right out of the cabinet ceiling.

The Reality of Top Mount Drawer Slides in Modern Cabinetry

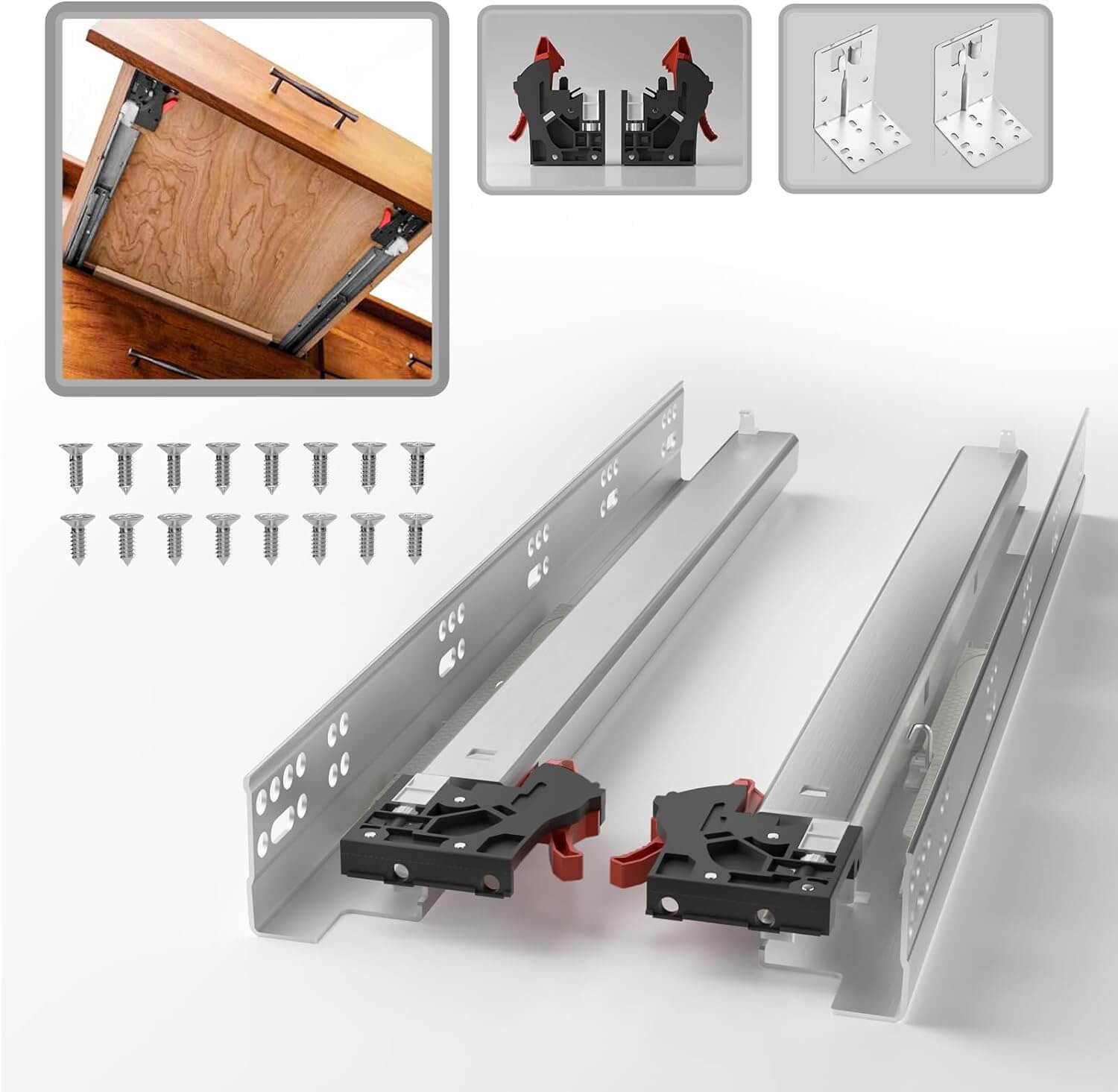

Let’s be real: you probably won't find these at a big-box store like Home Depot on a Tuesday afternoon. Most manufacturers, like Accuride or Knape & Vogt, treat them as specialized solutions. A top mount slide is exactly what it sounds like—the hardware attaches to the top of the drawer box and the underside of the cabinet shelf or carcass.

📖 Related: Overalls with Crop Top: Why This 90s Combo Still Works in 2026

Why would anyone do this?

Space. Usually, it's about space. When you’re retrofitting an old desk or working with a laboratory pull-out where the floor of the cabinet needs to stay completely clear for equipment, mounting from the top is your only move. It’s also a frequent flyer in the world of keyboard trays, though those are technically a sub-species of the top-mount family.

The physics are different here. Gravity is working against your fasteners rather than pushing the slide into the wood. Because of that, the load ratings on top mount drawer slides are notoriously lower than their side-mount cousins. If a side-mount is rated for 100 lbs, a top-mount version of similar size might only handle 30 or 50 lbs before the ball bearings start screaming. You have to account for the "pull-out" force on the screws.

When the Side-Mount Just Won't Cut It

Think about a pencil drawer. It's thin. It's wide. There is no "side" to speak of. If you try to put a side-mount slide on a 2-inch tall drawer, you're left with about zero structural integrity. In this specific scenario, the top mount is king. You see this a lot in institutional furniture—think hospitals or old-school libraries.

I’ve seen woodworkers try to "hack" a side-mount slide by just rotating it 90 degrees and screwing it to the top. Don't do that. Seriously. Ball-bearing slides are engineered for vertical loads. When you flip them horizontally, the bearings aren't seated in the races correctly. They’ll feel "crunchy" within a month. Real top-mount hardware uses a different race configuration to handle the lateral and suspended weight.

Installation Headaches You’ll Probably Encounter

Precision is everything. With a side-mount, if you're off by a 16th of an inch, you can usually shim it or adjust the drawer front. With top mount drawer slides, if your cabinet top isn't perfectly level or if your drawer box is slightly out of square, the slide will bind instantly.

- Measurement is a pain because you're working upside down inside a dark cabinet box.

- You need specialized screws. Standard #6 wood screws might not have the head diameter required to keep the slide from wobbling under tension.

- Clearance issues. You need to ensure the "drop" from the mounting surface to the drawer top is consistent across the entire depth of the cabinet.

If you’re working with frameless cabinets (Euro-style), it’s a bit easier. You’re just mounting to a flat panel. But if you’ve got face frames? Man, you're going to need to build out a mounting block or a "cleat" just to give the slide something to bite into. It’s extra work that most people don't anticipate.

Materials Matter More Than You Think

Steel is the standard, obviously. But the finish on your top mount drawer slides matters because they are often more exposed to the elements or cleaning chemicals in the specialized environments where they are used. Zinc plating is common. If you’re doing a lab or a high-moisture area, look for stainless steel options, though be prepared to pay a massive premium.

Accuride’s 2006 model is often cited as a benchmark for these, though even they have moved more toward "under-top" mounting for electronic applications. The market is shifting. We're seeing more friction-based slides in the ultra-cheap category, but for anything holding more than a few pens, ball bearings are non-negotiable.

👉 See also: SWX in the City: Why This Spokane Staple Still Hits Different

The Lateral Stability Myth

There’s this idea that top-mounted drawers are flimsier. Sorta true, sorta not.

If you use a single center-mounted top slide, yeah, it’s going to wobble like a loose tooth. But if you use two slides—one on each top edge—the stability is actually quite impressive. The trick is the "suspension" feel. Because the weight is hanging, the drawer tends to self-center as it closes. It’s a different tactile experience than the "clunk" of a bottom-mount.

But let’s talk about the "racking" problem. Racking is when one side of the drawer moves faster than the other, causing it to wedge itself shut. Because top mounts are often used on wider, shallower drawers (like those keyboard trays), racking is your biggest enemy. To fix this, you need slides with a high degree of "out-stop" rigidity.

Why the Industry is Moving Away (And Why That’s a Problem)

Cabinetry is becoming standardized. Everyone wants the "invisible" look of under-mount slides. This has pushed top mount drawer slides into the "specialty" catalog.

The downside? Prices are going up. If you're restoring a piece of mid-century modern furniture that originally used top-hung wooden runners and you want to upgrade to metal, you're going to find the options are surprisingly slim compared to the endless aisles of side-mounts.

It’s also harder to find "soft-close" versions for top mounts. The mechanism required to pull a hanging drawer shut quietly is more complex than one that sits on a rail. If you absolutely must have soft-close, you might have to engineer a hybrid system or look into some of the high-end European hardware brands like Hafele, who still cater to the weird architectural "one-off" projects.

Maintenance and Long-Term Survival

Here is the thing: dust.

Gravity pulls dust down. On a side-mount, the dust settles on the top of the rail and usually gets pushed out by the bearings. On a top-mount, the "trough" of the slide is often facing up or is enclosed in a way that traps debris. If you’re putting these in a workshop or a kitchen, you’re going to be cleaning them.

Use a dry lubricant. Never, ever use WD-40 or heavy grease on top mount drawer slides. It’ll just turn into a sticky paste that grinds the bearings down. A shot of PTFE (Teflon) spray or some dry graphite is all you need. If the drawer starts sticking, check the mounting screws first. Over time, the constant downward pull can slightly enlarge the pilot holes in MDF or particle board, causing the slide to sag just enough to ruin the alignment.

Making the Call: Should You Use Them?

If you have the side clearance, use side-mounts. If you have the bottom clearance and the budget, use under-mounts.

But if you are building:

- A shallow desk drawer under a thick stone countertop.

- A pull-out shelf in a medical cart.

- A hidden compartment in a closet where the floor must remain unobstructed.

Then the top mount is your best friend. It’s a tool for a specific problem. It isn't "worse" than other hardware; it's just misunderstood because it requires a higher level of "prep" work on the cabinet carcass. You can't just slap these on and hope for the best. You have to think like an engineer, considering the shear strength of your screws and the deflection of your cabinet ceiling.

Practical Steps for Your Next Project

Stop and measure your vertical clearance right now. If you have less than 1/2 inch on the sides but plenty of room above the drawer box, you're in the top-mount zone.

Start by verifying the weight of the drawer including its contents. If it's over 25 lbs, you need to be very picky about the slide's load rating. Look for "overhead mount" specifically in the technical data sheets.

When you go to install, use a template. Do not "eyeball" it. Even a 1/32-inch deviation from front to back will cause the drawer to creep open on its own or bind when you try to close it. Use a self-centering Vix bit for your pilot holes to ensure the screws go in perfectly straight. This prevents the screw head from sitting at an angle, which is the number one cause of "clicking" sounds in new drawer installations.

Finally, check the "over-travel" specs. Many top mount drawer slides are only 3/4 extension. If you need to reach the back of a deep drawer, make sure you specifically buy "full extension" top mounts. They exist, but they are bulkier and require more vertical headroom.

Once you get them dialed in, there is something deeply satisfying about a top-hung drawer. It feels like it's floating. It’s a clean look that keeps the bottom of your cabinets looking pristine and makes cleaning the floor of the cabinet a breeze since there are no tracks to catch crumbs and dust. It's a "pro" move, even if it's a bit of a headache to get there.