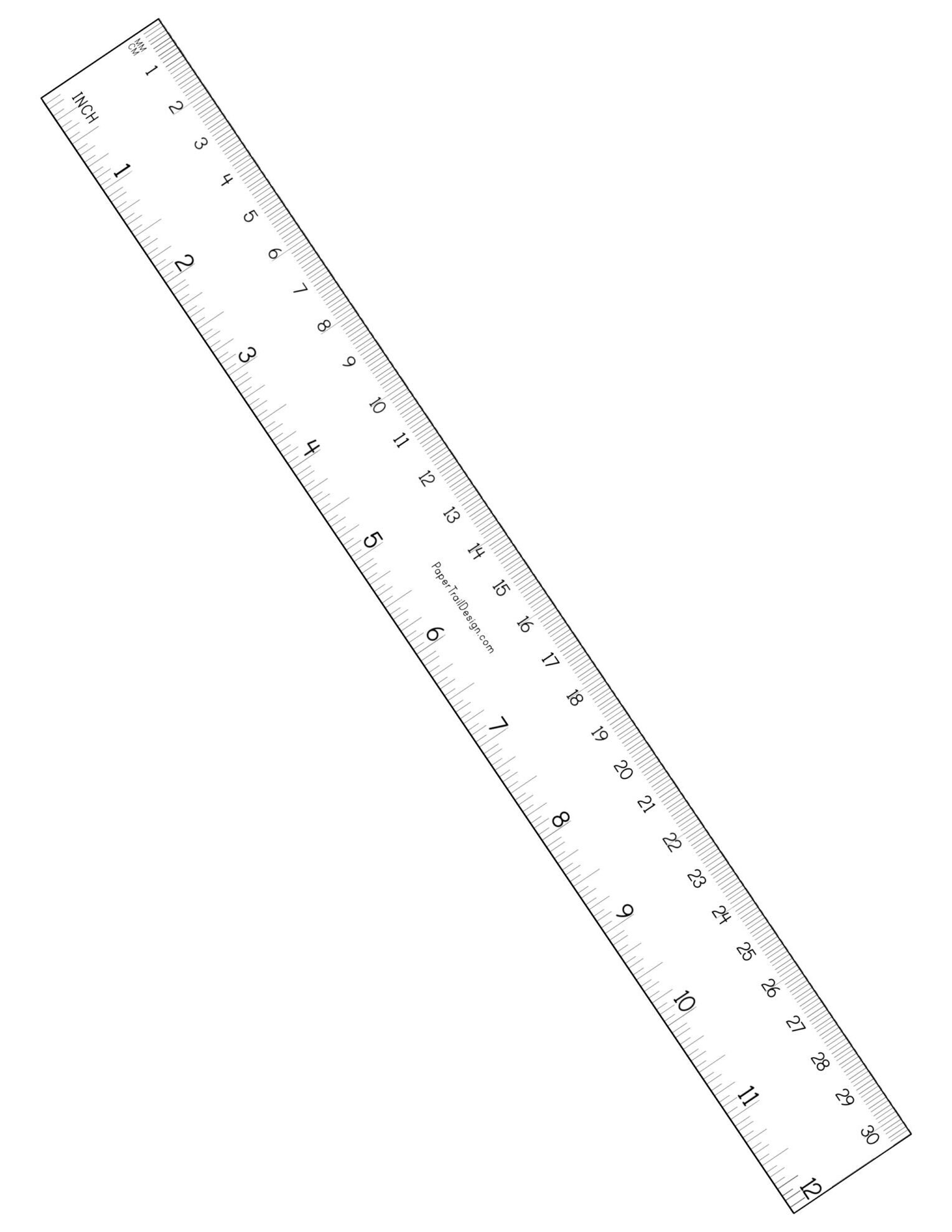

Ever looked at a standard 12-inch plastic ruler and wondered why the marks don't quite line up with the edge? It’s annoying. You’re trying to measure a piece of trim or a DIY craft project, and suddenly you realize that the "zero" line isn't actually at the very end of the physical stick. Most people just shrug and move on, but if you’re looking for precision, that tiny gap is a nightmare. Using a ruler in inches and cm seems like the simplest thing in the world, yet we constantly mess it up because we don't actually understand how these tools are manufactured or how the two systems of measurement actually talk to each other.

Measurement is weirdly personal. If you grew up in the United States, you think in eighths and sixteenths of an inch. If you’re literally anywhere else, you’re a metric devotee. But honestly, most of us have to live in both worlds. Your IKEA furniture is metric, but your house’s wall studs are 16 inches apart. You need a tool that handles both without making your brain hurt.

Why Your Ruler in Inches and Cm Might Actually Be Lying to You

Precision isn't guaranteed just because a factory printed lines on a piece of wood or plastic. In fact, cheap rulers are notoriously "off." Thermal expansion is a real thing. If you leave a plastic ruler in a hot car, it can actually stretch or warp. It sounds crazy, but a fraction of a millimeter change across 30 centimeters can ruin a technical drawing.

Professional draftsmen and machinists don't use the $1 back-to-school specials. They use stainless steel rules, often from brands like Starrett or Mitutoyo. Why? Because these are "engine-divided." This means the lines aren't just printed on top of the material; they are physically etched into the metal. When you run your fingernail across a high-quality ruler in inches and cm, you can feel the ridges. That depth ensures the marks don't rub off after three months of use.

Then there’s the "zero point" issue I mentioned earlier. On many cheap wooden rulers, the measurement starts exactly at the physical edge. Over time, the corners get bumped, rounded, or chipped. Once that corner is gone, your zero is gone. Better rulers have a "dead length" or a "clearance" before the first mark starts. This protects the integrity of the scale. If you're using a ruler where the zero is flush with the edge, you’re basically gambling with your accuracy every time you drop it.

💡 You might also like: Finding the most affordable way to live when everything feels too expensive

The Math Behind the Marks (And Why it Matters)

Let’s get nerdy for a second. An inch is defined exactly as 25.4 millimeters. It wasn't always that way. Before 1959, the US inch and the UK inch were slightly different. It was a mess. The "International Yard and Pound Agreement" finally settled the score, pinning the inch to the metric system. So, ironically, every time you use the "inch" side of your ruler, you are technically using a derivative of the metric system.

The metric side is decimal-based. It’s clean. Ten millimeters make a centimeter. A hundred centimeters make a meter. Easy. The imperial side is a chaotic nightmare of fractions. You’ve got halves, quarters, eighths, sixteenths, and sometimes thirty-seconds. To read a ruler in inches and cm effectively, you have to be able to switch mental gears instantly.

Most people struggle with the sixteenths. They’re those tiny little lines between the quarter-inch marks. If you find yourself counting "one, two, three..." tiny lines every time, you're doing it the hard way. Look at the heights of the lines. The half-inch mark is the longest (besides the whole inch). The quarter-inch is the next longest. The eighth-inch is shorter, and the sixteenth is the shortest. Once you start "reading" the heights of the lines rather than counting them, your speed triples.

Common Mistakes When Measuring Small Objects

I see people do this all the time: they lay the ruler on top of a 3D object and squint from an angle. This is called parallax error. If your eye isn't perfectly perpendicular to the mark on the ruler, the measurement will look shifted. It’s why your cuts are always 1/16th of an inch too short.

📖 Related: Executive desk with drawers: Why your home office setup is probably failing you

To fix this, you should always try to stand the ruler on its edge. This brings the markings directly into contact with the surface you’re measuring. It eliminates the gap between the scale and the object, which kills the parallax effect. It’s a simple trick, but it’s the difference between "close enough" and "perfect."

- Metric Strengths: Ideal for science, engineering, and any project where you need to add or subtract measurements quickly. Adding 4.7cm and 12.2cm is way easier than adding 1 7/8 inches and 4 13/16 inches.

- Imperial Strengths: Great for carpentry and things that need to be divided into thirds or halves repeatedly. An inch is a "human-sized" unit that feels intuitive for physical building.

- The Hybrid Reality: Most modern rulers show both because we live in a globalized world. If you're working on a car, you're likely using metric bolts. If you're hanging a picture frame in an American home, you're using inches.

Beyond the Standard Straight Edge

Not every ruler in inches and cm is a stiff stick. Tape measures are the most common variation, but they have their own quirks. Have you ever noticed the metal tip on a tape measure wiggles? People often try to "fix" this by hammering the rivets tight. Don't do that! That wiggle is intentional. It’s exactly the thickness of the metal hook itself. When you hook it over the end of a board, it pulls out to account for the thickness. When you butt it against a wall, it pushes in. That movement ensures that both internal and external measurements remain accurate.

Then you have calipers. If you really care about accuracy—like, down to the thousandth of an inch—a flat ruler won't cut it. Digital calipers allow you to toggle between inches and centimeters with a single button. They take the guesswork out of reading those tiny little lines.

Choosing the Right Tool for the Job

If you're just drawing a line for a school project, a plastic ruler is fine. But for anything else, consider these factors:

👉 See also: Monroe Central High School Ohio: What Local Families Actually Need to Know

- Material: Stainless steel won't warp or melt. It’s the gold standard.

- Graduations: Look for "etched" or "engraved" markings. If the numbers look like they’re just sitting on the surface, they’ll eventually disappear.

- Flexibility: Sometimes you need a ruler that can bend around a curved surface. Thin steel rulers are great for this; thick plastic ones will just snap.

- The "Zero" Point: Decide if you want a ruler that starts at the edge or one with a protective "dead space" at the beginning.

How to Get Better at Measuring Today

Stop guessing. If you're looking at a mark on a ruler in inches and cm and saying "it's about three little lines past the half-inch," you're setting yourself up for failure. Learn the decimal equivalents. Know that 1/8 is .125 and 3/8 is .375. This helps when you’re using a calculator to plan out a project.

Also, get into the habit of "burning an inch." If you don't trust the end of your ruler, start your measurement at the 1-inch mark (or 10cm mark) instead of the end. Just remember to subtract that extra inch from your final total! It’s a classic carpenter’s trick to ensure absolute precision when the end of the ruler is suspect.

Ultimately, a ruler is only as good as the person holding it. Whether you prefer the logic of the metric system or the traditional feel of imperial units, the key is consistency. Stick to one side for the duration of a single project. Mixing and matching halfway through is the fastest way to end up with a table that wobbles or a shelf that won't fit.

Next Steps for Accuracy:

Check the rulers you currently own. Place two different brands side-by-side and see if the marks actually line up. If they don't, throw the cheap one away immediately. Invest in one high-quality, etched stainless steel ruler for your "master" reference. Use that master ruler to verify your tape measures and plastic rulers every few months. This simple calibration check ensures that your "inch" is actually an inch every single time you build something.