You've probably seen those viral clips of a copper wire spinning wildly over a battery. It looks like magic. It isn't. It’s basically just physics doing its thing, but if you've ever tried to replicate it, you know it can be incredibly frustrating. One tiny kink in the wire or a slightly weak magnet and nothing happens. You’re just sitting there with a dead battery and a piece of copper that refuses to move.

Learning how to make a electromagnetic motor is a rite of passage for anyone interested in electronics. It’s the foundational principle that powers everything from the vibrator in your smartphone to the massive engines in a Tesla. We’re talking about the Lorenz Force. When you run an electric current through a wire, it creates a magnetic field. If that wire is sitting inside another magnetic field (from a permanent magnet), they push against each other.

The Basic Science Most People Gloss Over

Before you start stripping wires, you need to understand the "Why." Michael Faraday figured this out back in 1821. He realized that electricity and magnetism aren't separate things; they're two sides of the same coin.

When you connect your wire to the battery, electrons start sprinting. This flow creates a circular magnetic field around the wire. Think of it like an invisible sleeve of magnetism. When this "sleeve" meets the field of your neodymium magnet, the two fields interact. They either attract or repel. This interaction creates torque. Torque is just a fancy word for twisting force.

Most beginners fail because they don't realize that the motor needs a "break" in the circuit to keep spinning in one direction. If the current flows constantly in a simple coil, the magnetic push will just move the coil to one spot and hold it there. It gets stuck. To keep it spinning, you have to "time" the electricity, which is what a commutator does in a real motor. In a simple DIY version, we usually just scrape the insulation off one side of the wire to create a DIY switch.

What You’ll Actually Need

Don't go buying an expensive kit. You honestly probably have half of this in a junk drawer.

- Magnet Wire: This is thin copper wire coated with a very thin layer of enamel insulation. Don't use standard plastic-coated house wire; it’s too heavy and the insulation is too thick.

- Neodymium Magnets: These are the shiny, silver, super-strong ones. Ceramic (refrigerator) magnets are usually too weak for a basic build.

- A Battery: A standard AA or C-cell works best.

- Paperclips: Large ones. These will act as your "brushes" and the support structure.

- Electrical Tape: To hold everything together.

- Sandpaper or a Sharp Knife: This is the most important tool. You’ll use it to scrape the insulation.

Step-by-Step: Building Your First Motor

First, make your coil. Wrap the magnet wire around the battery about 10 to 15 times. Leave about two inches of straight wire sticking out on both ends. Slide the coil off the battery. It should look like a little circle with two arms. Wrap those arms around the circle a few times to hold the loops together. Make sure the arms are perfectly straight and diametrically opposite each other. If they’re off-center, your motor will wobble and die.

💡 You might also like: Dokumen pub: What Most People Get Wrong About This Site

Now comes the "make or break" part: the insulation.

Lay the coil flat on a table. Using your knife or sandpaper, scrape the enamel off the top half of both wire arms. Do not remove all the insulation. You want the copper to be bare on the top but still insulated on the bottom. This acts as a primitive commutator. When the bare copper touches the paperclips, the motor turns on. When the coil spins and the insulated side touches, the motor turns off. This "pulse" allows momentum to carry the coil around until it hits the bare copper again.

Setting Up the Base

Bend your paperclips into "U" shapes or little hooks. Tape one to the positive terminal of the battery and one to the negative terminal. Stand the battery upright. The paperclips should stick up like two goalposts.

Place your neodymium magnet right in the center of the battery, between the two paperclips.

Now, rest the wire arms of your coil in the paperclip hooks. If everything is balanced, and your scraping was precise, the coil should start to twitch. Give it a tiny flick.

Why It Isn't Spinning: Troubleshooting Like a Pro

If you’re staring at a motionless coil, don't throw it across the room yet. It's usually one of three things.

📖 Related: iPhone 16 Pink Pro Max: What Most People Get Wrong

1. The Balance is Garbage.

If your coil is lopsided, gravity will beat magnetism every time. The coil needs to be a perfect circle, and the "arms" need to be a straight line passing exactly through the center. Even a tiny bend will create too much friction or off-balance weight.

2. You Scraped Too Much (or Too Little).

If you scraped the insulation off the entire circumference of the wire, the magnetic field will push the coil to the "bottom" and just hold it there. It won't spin because there’s no "off" phase to let momentum take over. Conversely, if you didn't scrape enough, the electricity can't flow at all. You need that 50/50 split of bare copper and enamel.

3. Friction is the Enemy.

Sometimes the paperclips are too tight or the wire is too rough. Make sure the hooks are smooth. A tiny drop of light oil can help, but usually, it's just about making sure the wire can spin freely without catching.

Advanced Variations: The Homopolar Motor

If you want something even simpler but faster, try the homopolar motor. This is the one you see with the heart-shaped wire.

Basically, you stick the magnet to the bottom of the battery. You take a single piece of bare copper wire and shape it so the top touches the top terminal and the bottom lightly brushes against the side of the magnet.

It’s called "homopolar" because the polarity of the magnetic field and the current flow don't change. It's a constant stream of torque. These are incredibly fast but they drain batteries in minutes because they’re essentially a dead short. They also get very hot. Honestly, keep an eye on your fingers.

👉 See also: The Singularity Is Near: Why Ray Kurzweil’s Predictions Still Mess With Our Heads

The Real-World Impact

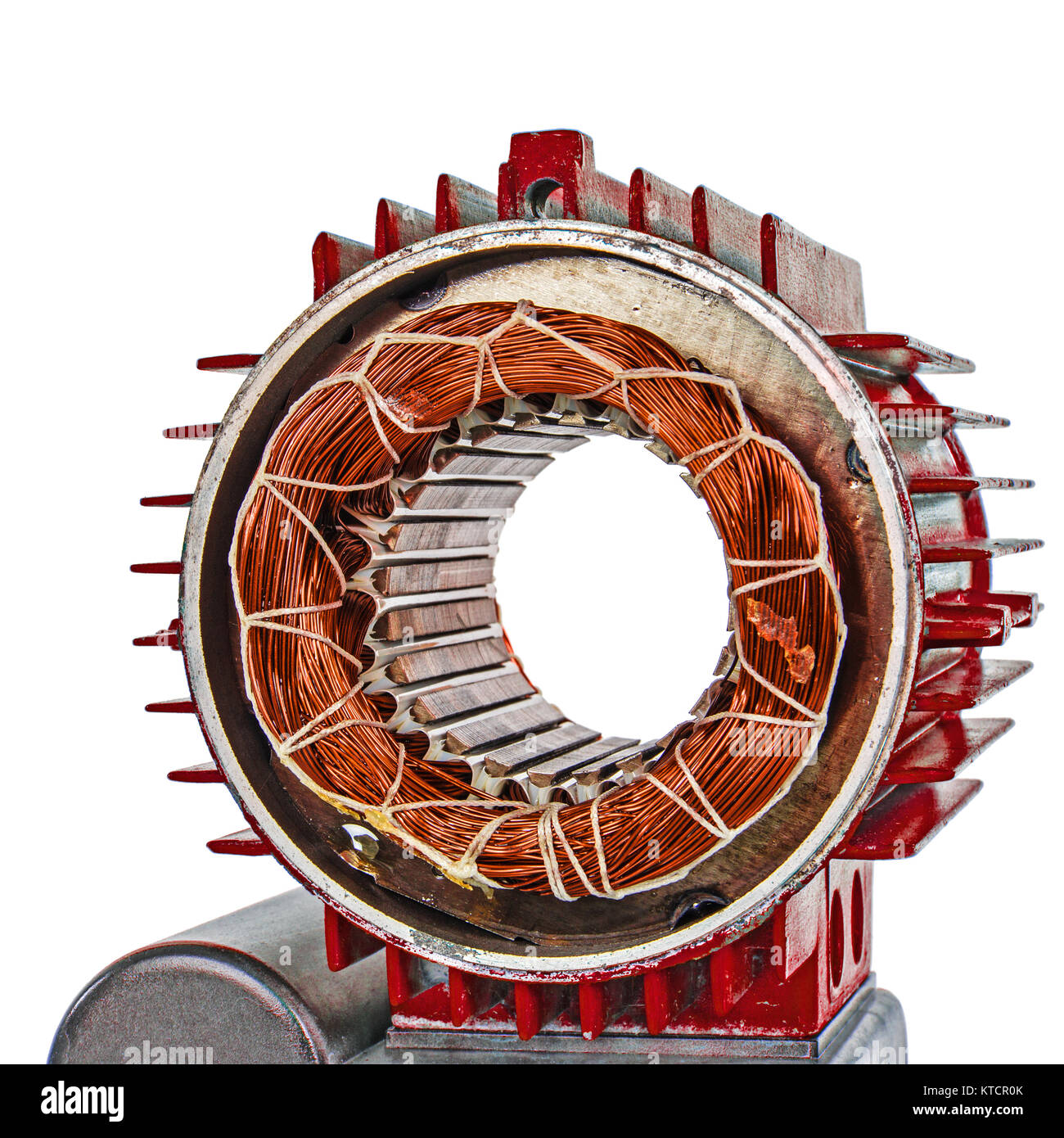

While a paperclip and a AA battery seem like a toy, the physics are identical to the massive motors in industrial pumps. Engineers at companies like Siemens or Tesla spend their lives optimizing exactly what you just did. They use better materials—like 99.9% oxygen-free copper and high-grade silicon steel—to reduce "eddy currents," which are tiny parasitic loops of electricity that waste energy as heat.

In a "real" motor, we don't use paperclips. We use a series of coils and a complex commutator (or electronic controllers in brushless DC motors) to flip the magnetic field at exactly the right microsecond. This ensures the motor is always "pushing" and never "stuck."

Safety Stuff (Because Batteries Aren't Toys)

Short-circuiting a battery—which is exactly what you're doing here—creates heat. If the coil stops spinning but stays connected, the wire will get hot enough to burn your skin or melt the plastic casing on the battery.

- Don't leave it running unattended.

- If it smells like burning, disconnect it.

- Use alkaline batteries. Lithium-ion batteries (like those 18650 cells) can be dangerous if shorted because they can vent or catch fire. Stick to the cheap Duracells for this.

Next Steps for Your Build

Once you get the basic motor spinning, try to optimize it. See how many wraps it takes to get the highest speed. Does a bigger magnet help, or does the weight become a problem?

You can also try building a Beedini Motor, which uses a circuit to pulse the magnet even more efficiently. Or, try to make a "Reversed" motor where the coil stays still and the magnet spins. That’s essentially how most modern computer fans work.

If you really want to level up, look into Lenz's Law and how it affects "back EMF." It’s the reason motors don't just accelerate to infinite speeds. The faster they spin, the more they actually start acting like generators, creating a counter-current that fights the battery. Science is weird like that.

- Check your wire gauge; 22-26 AWG is usually the sweet spot for these DIY projects.

- Test your battery with a multimeter to ensure it's actually pushing 1.5V.

- Experiment with different coil shapes—rectangles vs. circles—to see how the center of mass affects the RPM.