You're staring at a stack of cardboard. Maybe you’re shipping a vintage lamp you sold on eBay, or perhaps you're trying to figure out how much expensive rolls of sage-green wallpaper you actually need to cover a weirdly shaped built-in cabinet. You think, "It's just a box." Then you realize you don't want to overpay for shipping or, worse, run out of paper mid-project. That is exactly where a surface area of a box calculator saves your afternoon.

Most people treat surface area like a secondary thought. They obsess over volume—how much stuff fits inside. But volume won't tell you how much paint you need. Volume won't tell you if your heat dissipation for a custom PC build is going to fail. Surface area is the "skin" of the object, and calculating it is surprisingly easy to mess up if you’re just winging it with a tape measure.

The Basic Math Most People Forget

A box, or a rectangular prism if we're being fancy, has six sides. You’ve got the top and the bottom. You’ve got the front and the back. Then the two ends. If you just measure one side and multiply it by six, you’re assuming you have a perfect cube. Unless you’re shipping a literal dice, that’s almost never the case.

The formula is $SA = 2lw + 2lh + 2wh$.

Basically, you calculate the area of three different rectangles and then double them. You take the Length ($l$) times the Width ($w$), then the Length times the Height ($h$), and finally the Width times the Height. Add those three results together. Hit "multiply by two." Boom. You have the total surface area. But honestly? Doing that by hand while your kids are screaming or your boss is emailing you is a recipe for a decimal point disaster. A digital calculator handles the "oops" factor for you.

Why 3D Printing Changed Everything for Surface Area

Back in the day, surface area was just for painters and gift-wrappers. Now? If you’re into 3D printing, surface area is life. Every square millimeter of "skin" on a print requires a specific amount of filament and a specific amount of time for the nozzle to travel.

If you use a surface area of a box calculator to estimate the exterior of a prototype housing, you're getting a baseline for your material costs. Professional slicer software like Cura or PrusaSlicer does this deep in the code, but for a quick back-of-the-envelope cost estimate before you even open your CAD files, knowing the surface area of your bounding box is a pro move. It helps you decide if a project is even feasible before you waste eight hours on a failed print.

Shipping Costs and the Dimensional Weight Trap

FedEx and UPS don't just care about how heavy your box is. They care about how much space it takes up in the truck. This is called dimensional weight. While surface area isn't the direct metric they use for the price (that's volume), the two are inextricably linked.

If you use a box with a massive surface area to ship something tiny, you’re wasting money on the box material itself—the cardboard—and likely the tape needed to seal it. High surface area usually means high costs. I once saw a small business owner lose nearly 15% of their margin because they used "standard" boxes that were 2 inches too wide on every side. Those 2 inches increased the surface area significantly, which meant more packing peanuts and higher shipping tiers.

Heat Dissipation: The Science Part

Let’s talk about electronics. If you’re building a DIY power supply or a small server, the surface area of the enclosure acts as a radiator. Heat moves from the hot components inside to the cooler air outside.

The larger the surface area of the box, the better it can shed heat. This is why high-end amplifiers have those weird ridges (fins) on the side. Those fins aren't just for a "tough" aesthetic; they are there to artificially increase the surface area without making the box take up more room on your shelf. If you’re using a simple metal box for a project, calculating that surface area tells you if you have enough "skin" to keep your chips from melting.

Common Mistakes When Measuring

I see this all the time. People measure the inside of the box because that's where their item goes. But the surface area—especially for painting or wrapping—depends on the outside dimensions.

✨ Don't miss: How to Properly Clean Computer Screen Without Ruining the Coating

- The Flap Overlap: When you’re calculating for a cardboard box, the flaps overlap. A calculator gives you the geometric surface area, but you might need 10-15% more material if you’re actually constructing the box.

- Units Matter: Don't mix inches and centimeters. It sounds obvious, but it’s the #1 reason NASA lost the Mars Climate Orbiter. If you measure length in inches and height in centimeters, your result is complete gibberish.

- The Tape Factor: If you are "skinning" a box in fabric or vinyl, you need to account for the thickness of the material itself.

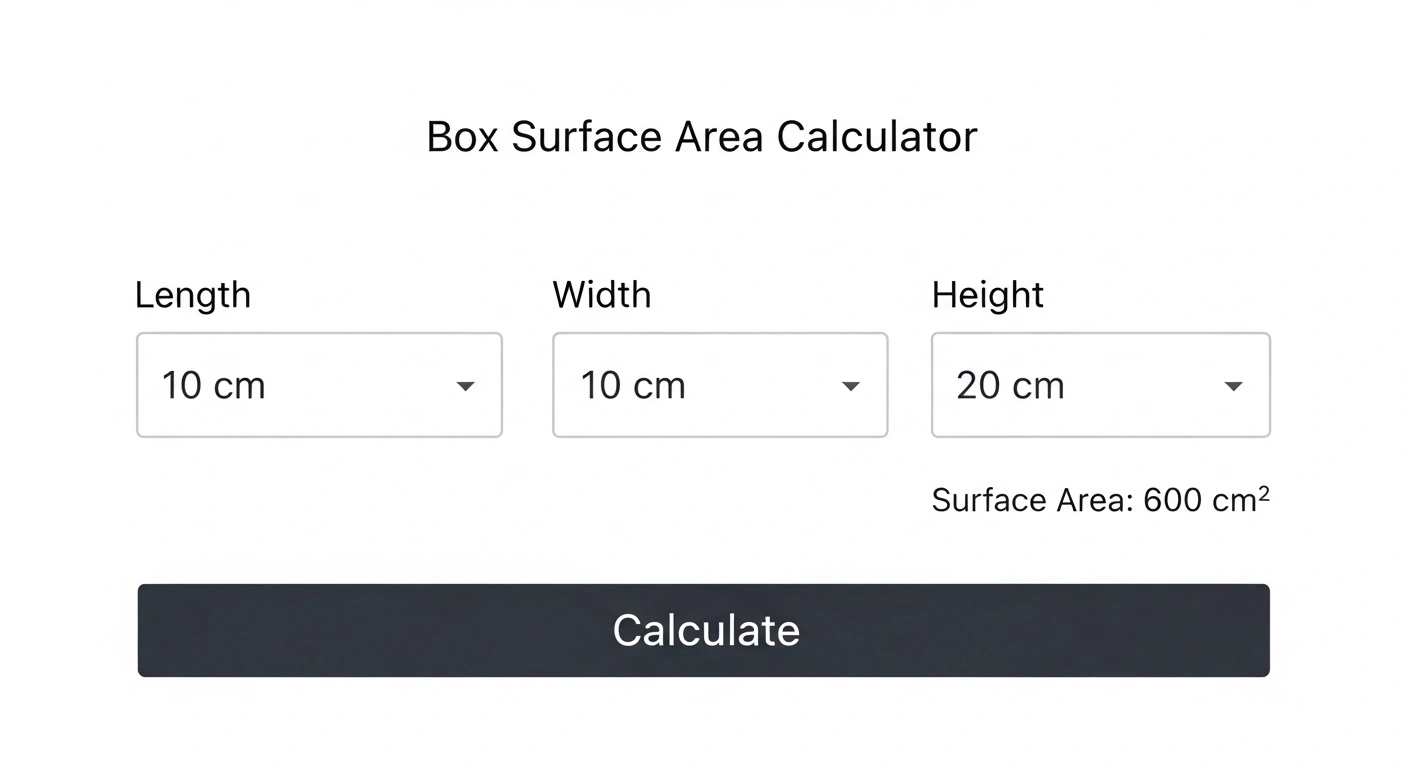

How to Use the Calculator Like a Pro

First, get your orientation right. Decide which side is the "front." It doesn't actually matter for the final math, but it keeps you from measuring the same side twice and skipping another.

- Measure the longest side (Length).

- Measure the side perpendicular to that (Width).

- Measure from the bottom to the top (Height).

Pop these into the tool. Most calculators allow for different units, so make sure you’ve selected the right one before hitting enter. If you’re doing this for a home DIY project, like painting a chest of drawers, remember to subtract the surface area of any parts you aren't painting—like the bottom that sits on the floor.

Beyond the Standard Rectangle

Sometimes your "box" isn't a perfect rectangle. Maybe it's a cube. For a cube, the math is even lazier: $6a^2$ (where $a$ is the length of one side).

But what if it's a triangular prism? Or a cylinder? A standard box calculator won't help you there. You’d need a specific tool for those geometries. However, for 90% of what we encounter in daily life—packages, rooms, cabinets, bricks—the rectangular box model is the gold standard.

Real-World Example: The "Moving House" Scenario

Think about moving. You have 50 boxes. You want to know how much plastic wrap you need to palletize them so they don't shift in the truck. If each box is 18x18x24 inches, one box has a surface area of 16 square feet. That's a lot of plastic. Without a quick calculation, you’d buy one roll of wrap and realize you're empty before you've even finished the first ten boxes.

👉 See also: Check Facebook Without Account: How to Browse Privacy-First in 2026

Actionable Next Steps

To get the most out of your calculations, don't just stop at the number. Apply these practical checks:

- Add a Buffer: Always add a 10% "waste factor" to your surface area result if you are buying materials like paint, fabric, or wrap.

- Check the Material: If you’re calculating for heat (like an electronics project), remember that material type matters as much as area. A plastic box with huge surface area won't dissipate heat as well as a smaller aluminum one.

- Round Up: In shipping, carriers usually round up to the nearest inch. Do the same with your measurements before putting them into the calculator to get a "real world" shipping estimate.

Verify your measurements twice. Use a metal tape measure, not a soft tailor's tape, which can stretch and give you a false reading. Once you have your numbers, the calculator does the heavy lifting, leaving you to focus on the actual project at hand.