Drive down Van Dyke Avenue in Michigan and you can't miss it. It’s huge. The Sterling Heights Assembly Plant, or SHAP if you’re hanging out with the UAW crowd, isn't just another building where things get bolted together. It is basically the heart of the American truck market. If this place stops, the economy feels it. Honestly, it’s kind of wild to think that a site that used to build missiles during the Cold War is now the reason you see so many Ram 1500s on the road.

Most people don't realize how close this place came to being a ghost town. Back in 2009, during the whole Chrysler bankruptcy mess, the "Old Chrysler" left SHAP for dead. It was on the closure list. It was done. But then something shifted. The city of Sterling Heights and the workers fought for it, and now? It’s arguably the most important asset in the Stellantis portfolio. It’s a 3-million-square-foot beast that proves manufacturing isn't dead in the Midwest; it just had to get smarter.

What Actually Happens Inside the Sterling Heights Assembly Plant

You’ve probably heard the term "just-in-time manufacturing." At SHAP, that isn't just a buzzword; it’s a survival tactic. The plant specializes in the Ram 1500, specifically the high-margin versions like the Limited, the Rebel, and the new Tungsten trims. These aren't just work trucks anymore. They’re luxury vehicles with beds. Because of that, the complexity inside those walls is staggering.

✨ Don't miss: Is the US Dollar Worth More Than a Euro? What Most People Get Wrong

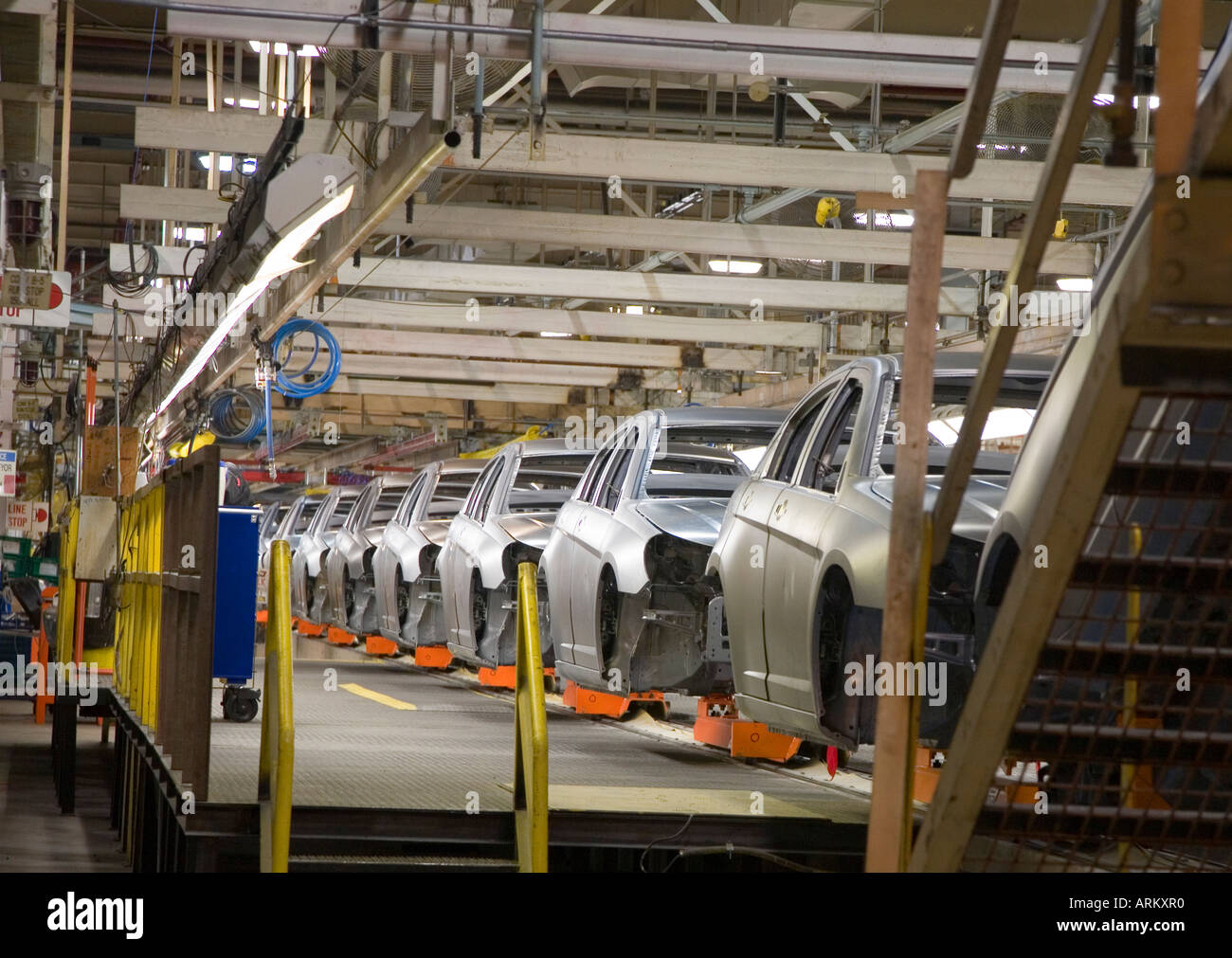

The assembly line is a masterpiece of logistics. You’ve got frames coming in, engines being dropped with sub-millimeter precision, and an army of robots doing the heavy lifting—literally. But the human element is what makes SHAP unique. There are over 7,000 employees here. That’s a small city’s worth of people working three shifts to keep up with the demand for the 5th-generation Ram.

One thing that surprises people is the body shop. It’s almost entirely automated. We’re talking hundreds of robots dancing around each other, sparks flying, welding aluminum and steel with incredible speed. It’s loud. It’s hot. It’s impressive. But then you get to general assembly, and it’s all about the hands. Humans are still better at tactile stuff—routing wiring harnesses or snapping in those massive 12-inch touchscreen interiors that people love so much.

The Massive Shift to Electric: RAM 1500 REV and Beyond

Things are changing. Fast. Stellantis is dumping billions into SHAP to make sure it doesn't get left behind in the EV transition. You might have seen the news about the Ram 1500 REV and the Ramcharger (the one with the onboard generator). Those are going to be built right here.

This isn't a small tweak.

To prep for the REV, the plant had to undergo massive retooling. They had to figure out how to handle 2,000-pound battery packs on a line that was built for internal combustion engines. It’s a bit of a jigsaw puzzle. You can't just stop production for a year to rebuild; they have to integrate these new technologies while still pumping out thousands of gas-powered trucks every week.

👉 See also: China Tariffs Explained: Why Your Amazon Cart Costs More in 2026

- Retooling the general assembly area to accommodate the STLA Frame platform.

- New battery installation stations that use specialized AGVs (Automated Guided Vehicles).

- Upgraded paint shop tech to handle the unique finishes of the premium electric models.

- Massive retraining programs for the UAW Local 1700 members.

The 2025 and 2026 model years are the real test. This is when the Sterling Heights Assembly Plant has to prove it can be a "multi-energy" facility. If they pull it off, it secures jobs for decades. If the transition is messy, well, we’ve seen what happens to one-trick pony towns in the Rust Belt.

The Local Impact: More Than Just a Tax Base

If you live in Macomb County, you know someone who works at SHAP. Or you know someone who sells parts to SHAP. Or you eat at the diners where the third-shift workers grab breakfast at 7:00 AM. The economic footprint is massive. When the plant got a $1.49 billion investment recently, the whole region breathed a sigh of relief.

It’s not just about the paychecks, though. It’s about the identity. Sterling Heights is a blue-collar town with a white-collar future, and this plant is the bridge. The relationship between Stellantis and the UAW here has been... let’s say "spirited" at times. You probably remember the 2023 strikes. That wasn't just about money; it was about ensuring that as we move to EVs—which require fewer parts and potentially less labor—the people who built the company don't get tossed aside.

The new contract reflected that. It included commitments for the new electric products, which basically guaranteed that SHAP stays the flagship. It’s a symbiotic relationship. Stellantis needs the expertise of the Sterling Heights crew, and the crew needs the massive capital only a global giant can provide.

👉 See also: Retirement Age in 1980: What Really Happened Before Everything Changed

Why Quality Control at SHAP is a Different Beast Now

In the past, American trucks sort of had a reputation for being "good enough." Those days are over. The Sterling Heights Assembly Plant had to pivot to compete with the likes of Ford's Rouge plant and GM's facilities.

They use something called "Metrology Centers." Basically, they take a finished truck and use lasers to measure every single gap and flushness point to within the width of a human hair. If the hood is off by a fraction of a millimeter, the system catches it. This is why the Ram 1500 has been cleaning up on J.D. Power and MotorTrend awards lately. It’s not luck. It’s the result of a very specific, very expensive shift in how the plant operates.

Real Talk: Challenges Still Remain

It’s not all sunshine and robots. The transition to electric vehicles is risky. If the market for $70,000 electric trucks isn't as big as Stellantis thinks, SHAP will have to pivot again. There’s also the supply chain. We all remember the microchip shortage. A plant this big is vulnerable. If one sensor from a supplier in Taiwan doesn't show up, the whole line stops.

And stopping the line costs millions of dollars per hour. Literally.

The Evolution of the Site: From Missiles to Machining

The history here is actually pretty cool. During the 1950s, this site was the Michigan Missile Plant. They built Redstone and Jupiter missiles. You can still feel that "industrial fortress" vibe when you walk around the perimeter. Chrysler bought it in the 80s to build the LeBaron.

Think about that for a second.

This facility went from Cold War weaponry to 80s convertibles to the most advanced pickup trucks on the planet. That kind of flexibility is rare. It’s built into the DNA of the workforce. They know how to reinvent themselves because they’ve had to do it every twenty years just to stay relevant.

Actionable Insights for Following the Industry

If you’re watching the automotive space, specifically Stellantis and the Sterling Heights Assembly Plant, here is what you should be looking for in the coming months:

- Watch the Inventory Levels: If you see the lots surrounding the plant filling up with un-shipped trucks, it’s a sign of either supply chain hiccups or a cooling market.

- Monitor the "Ramcharger" Launch: This truck is a massive gamble. It’s an EV with a gas engine that only acts as a generator. Since it’s being built at SHAP, its success or failure will dictate the production pace of the entire facility.

- Local Job Postings: Stellantis often hires in waves for new product launches. Keeping an eye on their careers page for "Sterling Heights" gives you a pulse on how fast they are ramping up the REV lines.

- The 2025 Power Move: With the Hemi V8 being phased out for the Hurricane Twin-Turbo Inline-6, the SHAP assembly line is currently undergoing its biggest mechanical shift in years. Keep an eye on initial quality reports for the "Hurricane" engines—that's the real test for the assembly team.

The Sterling Heights Assembly Plant is more than just a factory. It’s a giant, breathing organism that keeps the American automotive dream on life support during the tough times and powers it during the good ones. Whether you're a truck fan or just interested in how stuff gets made, what happens on Van Dyke Avenue matters. It’s where the rubber—quite literally—meets the road.