If you’ve ever walked past a construction site and thought all those red blocks looked identical, you’re actually looking at one of the most organized mathematical illusions in the world. It’s wild. You see a wall, but a mason sees a grid of numbers where a single 1/2-inch mistake can ruin an entire facade. Understanding brick and mortar dimensions isn't just for architects or people wearing hard hats; it’s basically the "cheat code" for anyone planning a home DIY project or trying to figure out why their garden wall looks slightly crooked.

Bricks aren't just blocks of clay. They are units of measurement.

Most people get tripped up because they look at a brick and see its "actual" size. But in the world of masonry, the actual size is almost irrelevant. What matters is the "nominal" size. This is where the math gets a little weird. If you go to a big-box retailer like Home Depot or Lowe's, you might see a standard modular brick. Its actual physical size is $3 \text{ 5/8"} \times 2 \text{ 1/4"} \times 7 \text{ 5/8"}$.

Wait. Why the weird fractions?

Because the industry assumes a 3/8-inch mortar joint. When you add that mortar to the brick, it magically transforms into a perfect $4" \times 2 \text{ 2/3"} \times 8"$ unit. That’s the nominal size. It’s designed this way so that three courses of brick (brick + mortar) equal exactly 8 inches in height. It aligns perfectly with concrete blocks (CMUs), which are also based on an 8-inch module. Everything in a building is trying to shake hands with everything else.

The Secret Language of Brick Sizing

You’ve probably heard terms like King, Queen, or Utility. It sounds like a weird deck of cards, but these names dictate the rhythm of a building.

The Modular Brick is the industry sweetheart. It’s the one we just talked about. It fits the 4-inch grid perfectly. But then you have the King Size Brick. These are super popular in residential neighborhoods across the South and Midwest of the United States. A King brick is typically about $9 \text{ 5/8"}$ long. Why use them? Honestly, it’s about money and speed. Because the brick is longer and taller, you need fewer of them to cover a square foot of wall. Fewer bricks mean less labor. Less labor means a lower bill from your mason.

🔗 Read more: Weird White People Names: What Most People Get Wrong

Then there’s the Roman Brick. These are long, skinny, and look incredibly "mid-century modern." Think of the Robie House by Frank Lloyd Wright. They emphasize the horizontal line of a house, making it look grounded and sleek. But man, they are a pain to lay. Because they are thinner, you need more "courses" (rows) to reach the top of a wall, which drives labor costs through the roof.

And don't even get me started on Utility Bricks. These are the giants. They are usually $3 \text{ 5/8"} \times 3 \text{ 5/8"} \times 11 \text{ 5/8"}$. You’ll see these on schools, hospitals, or Target stores. They aren't "pretty" in a traditional sense, but they are efficient. One Utility brick does the work of three standard modular bricks.

Mortar Joints: The Glue That’s Not Just Glue

Mortar isn't just the stuff that holds the bricks together. It’s a structural cushion. It also takes up roughly 20% of the surface area of a brick wall. That is a huge percentage! If you pick a dark brick but use a bright white mortar, the wall is going to look grey from the street.

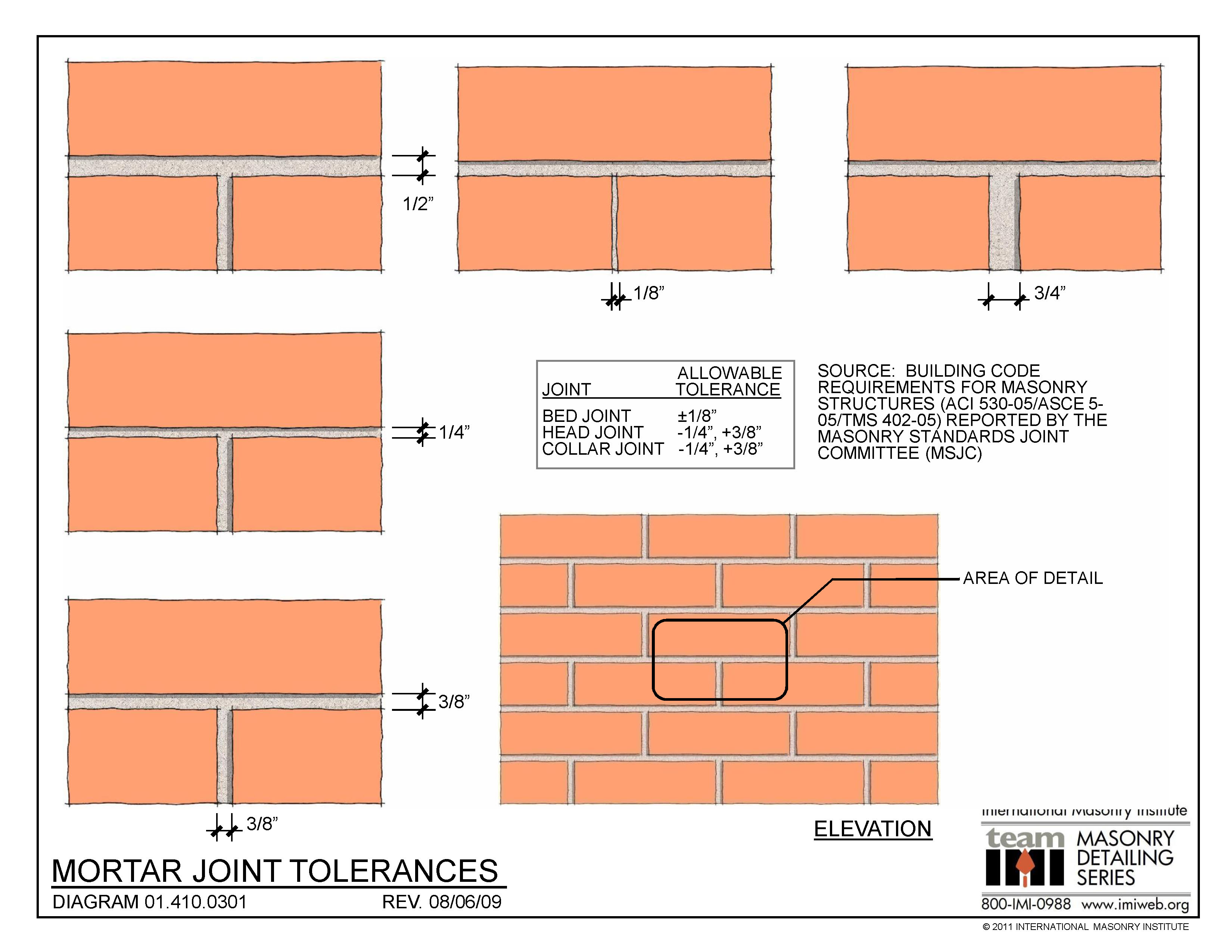

The standard thickness for brick and mortar dimensions is almost always 3/8 of an inch.

If you go thinner, say 1/4 inch, you’re asking for trouble. Bricks aren't perfectly flat. They have slight bows and "kiln marks." The mortar joint acts as a shock absorber for these imperfections. If the joint is too thin, the bricks might actually touch each other, which leads to "spalling"—where the face of the brick literally pops off because of pressure or ice expansion.

On the flip side, you have the "Oversized" or "Grapevine" joints. Some people love the "weeping mortar" look where the mortar oozes out of the joint and stays there. It looks like a fairytale cottage or something out of The Hobbit. It’s a vibe, for sure, but it's a nightmare for water shedding.

Why the 3/8-Inch Rule Rules

- Tolerance: It hides the fact that the brick you bought might be 1/16th of an inch off.

- Bonding: It allows the mortar to "grab" the pores of the clay.

- Expansion: Buildings breathe. They grow in the sun and shrink at night. The mortar joint is the "lung" that allows this movement without the wall cracking in half.

Real-World Math: How Many Bricks Do You Actually Need?

Let’s say you’re building a mailbox or a small retaining wall. You measure the area and it's 100 square feet. You can’t just divide that by the size of a brick. You have to account for the waste and the mortar.

For standard modular bricks, the rule of thumb is 7 bricks per square foot.

If you use King Size, it’s closer to 5.1 bricks per square foot.

See the difference? Over a whole house, that’s thousands of dollars. But here’s the kicker: you always, always order 5% to 10% more than you need. Why? Because bricks break. They arrive on the pallet with chipped corners. Or the guy at the saw makes a bad cut. Also, brick "dye lots" are a real thing. If you run out of bricks and order more two weeks later, they might come from a different part of the kiln and have a slightly different shade of red. Your house will have a "scar" where the new bricks start. It’s not a good look.

Common Mistakes People Make with Dimensions

The biggest mistake is ignoring the "nominal" vs "actual" distinction. I’ve seen DIYers plan a window opening based on the actual length of five bricks, only to realize on-site that they forgot to account for the four mortar joints between them. Suddenly, the window doesn't fit, the header is too short, and everyone is grumpy.

Another thing is the "Head Joint." That’s the vertical mortar line. In a proper "Running Bond" pattern, the head joint of one row should be exactly in the middle of the brick below it. If your dimensions are off by even a fraction, those vertical lines will start to "stair-step" or drift. It’s called "losing the bond," and it’s a sign of a bad masonry job.

Expert Tip: The Story Pole

Real masons don't just wing it. They use a "story pole." It’s basically a long stick marked with the exact height of every course of brick and mortar. They stand it up at the corners of the building to make sure the left side of the house is the same height as the right side. If you’re doing a project at home, make your own story pole. It’ll save your life.

The Technical Side: Compressive Strength and Absorption

We can't talk about dimensions without talking about what's inside the brick. Not all bricks are created equal. You have "Severe Weathering" (SW) grade and "Moderate Weathering" (MW).

📖 Related: Is Isolated Thunderstorms Dangerous? Why This Weather Forecast Often Fools People

If you live in a place like Chicago or Boston where it freezes and thaws every five minutes, you need SW bricks. These bricks are denser and usually have slightly tighter dimensional tolerances. They absorb less water. If a brick absorbs too much water and then freezes, it expands and cracks. This is why you see old buildings with "flaking" bricks.

The mortar has to be weaker than the brick. This sounds counterintuitive, right? You’d think you want the strongest mortar possible. Nope. If the mortar is stronger than the brick, the brick will crack when the house settles. If the mortar is slightly softer (like a Type N mortar), the mortar will develop tiny hairline cracks instead, which are easy to fix. It’s much cheaper to repoint mortar than to replace a structural brick.

Modern Innovations in Masonry Units

We’re starting to see "Thin Brick" take over the interior design world. These are usually about 1/2-inch to 1-inch thick. They give you the look of a brick wall without the weight or the need for a massive concrete footing. But even with thin bricks, the brick and mortar dimensions follow the same rules. You still want that 3/8-inch joint to make it look "real." If you butt them up against each other without a joint, it looks like a cheap kitchen backsplash.

There’s also the rise of engineered "BIM" (Building Information Modeling). Architects now use software to calculate every single brick in a skyscraper before a single one is laid. This reduces waste to almost zero. It’s incredibly efficient, but it lacks the soul of a mason who can look at a wall and "adjust" the joints by a hair to make everything line up perfectly by the time they hit the roofline.

How to Plan Your Project

- Identify your brick type early. Don't just say "red brick." Pick the specific manufacturer (like Glen-Gery or Belden) and get the spec sheet.

- Calculate the "Course Height." For most residential bricks, this is 2.66 inches.

- Check your local codes. Some areas require specific mortar types (Type S for high wind, Type N for general use).

- Buy the whole batch at once. Ensure they come from the same production run to avoid color "banding."

- Don't forget the ties. Bricks aren't usually the structural wall; they are a "veneer." You need metal ties to hook the brick to the wooden studs behind it.

Building with brick is an ancient art, but it’s governed by very modern, very strict geometry. Once you see the grid, you can’t unsee it. You’ll start looking at every fireplace, every pizza oven, and every library wall differently. You'll see the 3/8-inch heartbeat that holds the whole thing together.

Getting the dimensions right isn't about being a perfectionist; it's about making sure that what you build today is still standing fifty years from now. It's about respecting the math of the clay.

Actionable Next Steps

If you are planning a masonry project, your first move is to go to a local masonry supply yard—not a general hardware store. Ask to see a "sample board" of different sizes. Physically hold a Modular brick next to a Queen brick. You will immediately feel the difference in weight and scale. Once you pick a size, grab a "mason's ruler." It’s a special folding ruler that has standard inches on one side and "brick spacing" scales on the other. It does all the nominal math for you so you don't have to carry a calculator around the job site.