If you’ve ever stood in a warehouse or on a job site looking at a stack of metal, you know the feeling. You need a 2-inch pipe. But "2 inches" doesn't actually mean 2 inches. It’s a mess. Honestly, the stainless steel pipe schedule table is basically the secret decoder ring for the entire piping industry, and if you misread it, you’re looking at thousands of dollars in wasted material or, worse, a burst line.

Most people think "Schedule" refers to the strength of the steel. It doesn't. Not really. It’s about geometry. It’s about how much "meat" is on the bone—the wall thickness relative to the outside diameter. Because stainless steel is pricey and resists corrosion so much better than carbon steel, we use different schedules (like 5S or 10S) that you’d never see in the heavy-duty world of black iron.

Why the "S" Matters More Than You Think

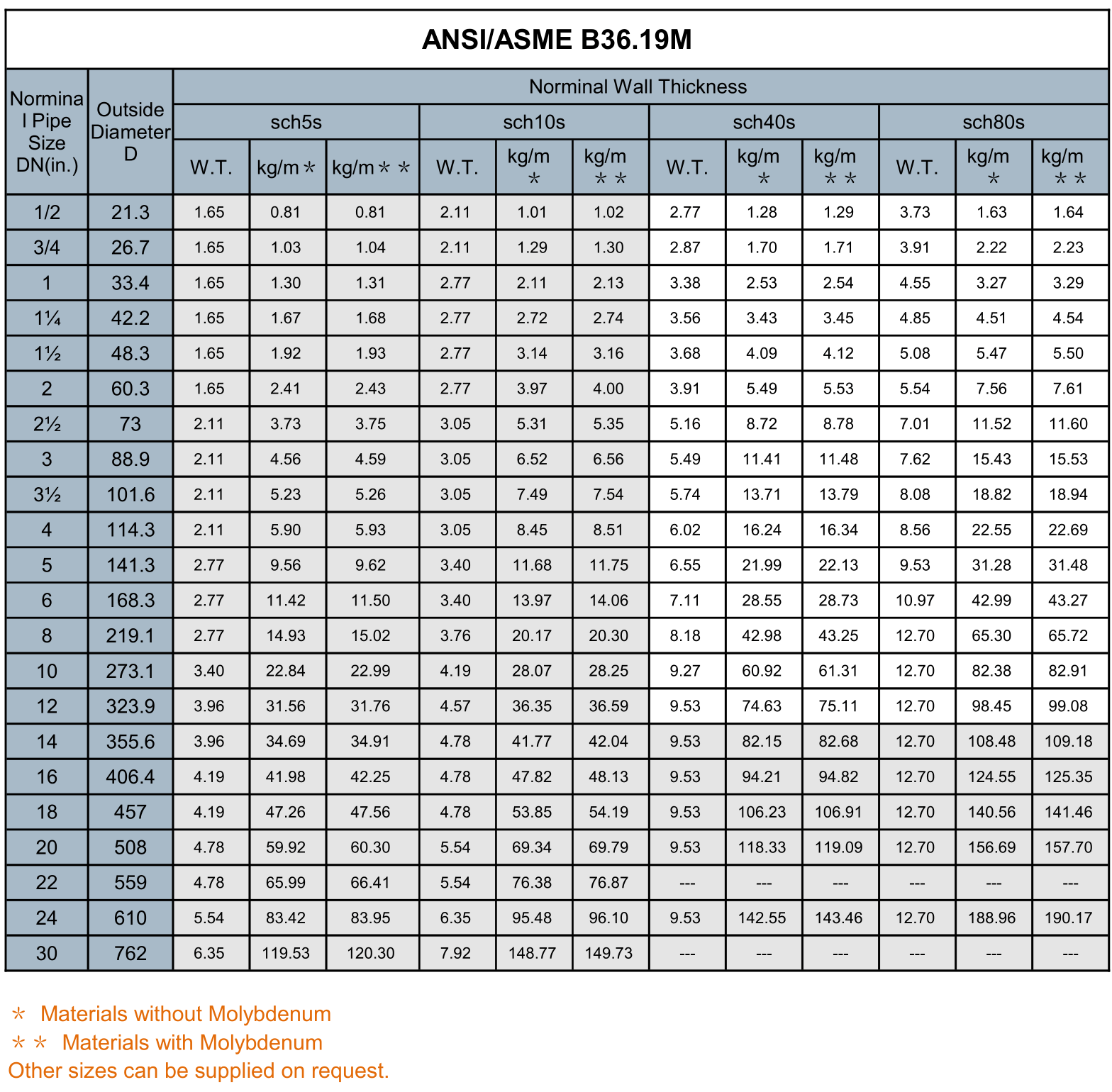

When you’re looking at a stainless steel pipe schedule table, you’ll notice a little "S" after the numbers. Schedule 40S. Schedule 80S. That "S" stands for Stainless. Seems simple? Sorta.

In the world of carbon steel, governed by ASME B36.10, schedules go up to 160 or even XXS (Double Extra Strong). But stainless steel follows ASME B36.19. The "S" schedules were created because stainless is an overachiever. Since it doesn't rust away like carbon steel, you don't need a massive "corrosion allowance." You can get away with thinner walls. If you tried to use a Schedule 5 carbon steel pipe, it would probably rust through before you even finished the weld. But Schedule 5S stainless? That’s a standard in many chemical plants.

If you ignore that "S," you might accidentally order a wall thickness that is significantly heavier (and more expensive) than what the engineer actually specified. Or you might find yourself trying to weld two pipes together that don't actually line up because their internal diameters are completely different.

The NPS Mindset Shift

Let’s talk about Nominal Pipe Size or NPS. It’s a lie.

If you grab a tape measure and check a 1/2-inch pipe, the outside diameter (OD) is actually 0.840 inches. Why? Because back in the day, the 1/2-inch referred to the inside diameter. As manufacturing improved and we started using different wall thicknesses, we had to keep the OD constant so the fittings would still fit.

So, across the entire stainless steel pipe schedule table, the OD stays fixed for a given NPS. If you buy a 4-inch pipe, the OD is always 4.500 inches. Always. Whether it's Schedule 5S or Schedule 80S. What changes is the hole in the middle.

Breaking Down the Thickness Variations

Let's look at a 2-inch NPS pipe to see how wild this gets.

The OD is a rock-solid 2.375 inches.

If you’re looking at Schedule 5S, your wall thickness is a mere 0.065 inches. It’s light. You can carry it with one hand. But if you jump up to Schedule 80S, that wall thickness balloons to 0.218 inches.

Think about that.

The pipe hasn't gotten any bigger on the outside, but the "hole" on the inside has shrunk from 2.245 inches down to 1.939 inches. If you’re trying to pump a thick slurry through there, that reduction in ID is going to skyrocket your pressure drop.

The Schedule 10S and 40S Dominance

In the field, you’re going to see Schedule 10S and Schedule 40S about 90% of the time.

Schedule 10S is the "budget" king of the stainless world. It’s thick enough to weld easily but thin enough to keep the weight and cost down. It’s the go-to for water treatment, food and beverage, and semi-conductors.

Schedule 40S is the heavy hitter. It’s roughly equivalent to "Standard" weight in carbon steel. It’s what you use when you have high-pressure steam or you're worried about mechanical damage. If a forklift bumps into a Schedule 10S pipe, it’s going to dent. If it hits a Schedule 40S pipe, the forklift might be the one that ends up with a bruise.

💡 You might also like: How Do You Deactivate Facebook Account Processes Without Losing Your Photos

Real-World Math: Pressure vs. Weight

Engineers don't just pick a schedule out of a hat. They use the Barlow’s Formula. It’s the gold standard for figuring out how much pressure a pipe can take before it turns into a banana peel.

$$P = \frac{2St}{D}$$

In this case, $P$ is the internal pressure, $S$ is the allowable stress of the material (which changes based on the grade, like 304L vs 316L), $t$ is the wall thickness from your stainless steel pipe schedule table, and $D$ is the outside diameter.

Notice that the wall thickness ($t$) is on the top of the fraction. Thicker wall equals higher pressure. But $D$ is on the bottom. This is why a 1/2-inch pipe at Schedule 40 can handle way more pressure than a 24-inch pipe at Schedule 40. The larger the diameter, the more "hoop stress" the steel has to fight.

The Confusion Between Tubing and Pipe

This is where things get genuinely dangerous. I’ve seen it happen.

Pipe is measured by NPS and Schedule.

Tubing is measured by actual OD and wall thickness.

If you ask for "1-inch stainless pipe," you are getting something with a 1.315-inch OD. If you ask for "1-inch stainless tube," you are getting exactly 1.000 inch OD. They are not interchangeable. You cannot use a pipe hanger on a tube of the "same" size. You cannot use a pipe flange on a tube.

The stainless steel pipe schedule table is your safeguard against this. If you can't find your dimension on that table, there’s a high chance you’re actually looking at tubing or a proprietary "instrumentation" line.

👉 See also: How Do I Share an App on iPhone: The Ways Apple Doesn’t Exactly Make Obvious

Grades Matter: 304 vs 316

While the schedule table tells you the dimensions, the "grade" tells you the soul of the pipe.

304/304L is the "everyday" stainless. It’s what your kitchen sink is made of. It works for most things. But if you’re near the ocean or dealing with chlorides (basically salt), 304 will "pit." It gets these tiny little pinholes that look like nothing but go all the way through the wall.

That’s when you step up to 316/316L. It has Molybdenum added to the mix. That one ingredient makes it resistant to chloride corrosion.

The "L" stands for Low Carbon.

Use it.

Always.

Old-school 304 or 316 had higher carbon, which meant when you welded it, the carbon would suck up the chromium and create "sensitization." Your weld would rust. Modern 304L and 316L have so little carbon that you can weld them all day without ruining the corrosion resistance.

What No One Tells You About Tolerance

The stainless steel pipe schedule table gives you "nominal" values. In the real world, ASTM A312 (the standard spec for seamless and welded stainless pipe) allows for a wall thickness tolerance. Usually, it's around 12.5%.

That means if the table says the wall is 0.100 inches, the pipe you receive could be 0.0875 inches and still be "perfectly legal."

If your design is right on the edge of a pressure limit, you can't rely on the nominal number. You have to account for that 12.5% "mill tolerance." It’s the difference between an engineering success and a catastrophic failure.

Weight Calculations for Logistics

If you’re a project manager, the schedule table is how you calculate your freight costs. Stainless steel isn't light.

To find the weight of your pipe in pounds per foot (lb/ft), you can use this handy little formula:

$$W = 10.69(D - t)t$$

🔗 Read more: Images of Space Planets: What They Actually Look Like and Why It Matters

$W$ is weight, $D$ is OD, and $t$ is wall thickness.

If you’re running 500 feet of 6-inch Schedule 40S pipe, you better realize that’s roughly 9,500 pounds of steel. You’re going to need more than a pickup truck to move that.

A Note on Seamless vs. Welded

The stainless steel pipe schedule table applies to both, but their price tags are wildly different.

Welded pipe is made from a flat strip of steel rolled into a tube and zipped up with a laser or TIG weld. It’s cheaper. For most applications, the "weld bead" is so well-integrated you can't even see it.

Seamless pipe is made by piercing a solid round bar of steel. No weld. No weak point. It’s what you use for high-pressure or high-temperature stuff where you don't want to bet your life on a weld seam. Seamless is usually 30% to 50% more expensive.

Actionable Steps for Your Next Project

Don't just wing it.

- Verify the OD first. Use a caliper. If it doesn't match the standard OD for that NPS on the table, stop. You have tubing, not pipe.

- Check the "S". Ensure you aren't using a carbon steel table for a stainless project. The wall thicknesses for Sch 40 and Sch 40S are often the same, but for Sch 10 and Sch 10S, they can differ significantly.

- Account for Mill Tolerance. Always assume your pipe is 12.5% thinner than the table says when doing your safety math.

- Specify 304L or 316L. Avoid the non-L grades unless you have a very specific metallurgical reason to use them. It makes the welding process foolproof.

- Match your fittings. Ensure your elbows, tees, and flanges are the same schedule as your pipe. A Schedule 10S pipe welded to a Schedule 40S elbow creates a "lip" inside the pipe that causes turbulence and erosion.

The stainless steel pipe schedule table is a foundational tool. Use it to cross-reference your physical measurements before you strike an arc or turn on a pump. If the numbers on your caliper don't match the numbers on the page, something is wrong. Trust the table, verify the material, and always double-check the "S".