Ever walked through a hardware aisle and felt that low-grade headache starting? It's the wall of silver. Thousands of tiny steel bits, all looking identical, yet if you pick the wrong sheet metal self tapping screws, your HVAC ductwork will rattle loose in a month or your backyard shed will start weeping rust streaks down the siding. It's frustrating. Most people think a screw is just a screw, but in the world of fastening thin-gauge metal, the physics are actually pretty wild.

You’ve got to understand one thing right out of the gate: "self-tapping" is a broad umbrella that covers a lot of sins. Some people use the term for anything that goes into metal. They're wrong. Technically, there is a massive difference between a thread-forming screw and a thread-cutting screw. One pushes the metal out of the way to create a tight, friction-fit seal, while the other literally carves out a path like a tiny drill bit. If you’re working with thin aluminum versus heavy galvanized steel, picking the wrong one isn't just a minor "whoops"—it's the difference between a structural bond and a stripped hole that won't hold a feather.

The Pilot Hole Problem: Tapping vs. Drilling

Here is the secret most big-box retailers don't emphasize enough. A standard sheet metal self tapping screw—often called a Type A, AB, or B—requires a pre-drilled pilot hole. It "taps" its own threads, sure, but it isn't a drill. If you try to force a standard tapping screw into a solid sheet of 18-gauge steel without a hole, you’re just going to burn out your driver bit or snap the head off the fastener.

Contrast that with self-drilling screws, frequently called "Tek" screws (a brand name that became the generic term, much like Kleenex). These have a tip that looks like a miniature twist drill.

- Self-drilling screws (Tek): These drill the hole, tap the thread, and fasten all in one go. They save massive amounts of time on commercial jobs.

- Self-tapping screws (Thread-forming): These require a hole but provide much higher vibration resistance because they displace the metal rather than removing it.

The "grip" of a screw in sheet metal relies on the "engagement" of the threads. In very thin material, you might only have two or three threads actually touching the metal. That’s a precarious situation. If you use a screw with a pitch that's too wide, the metal might sit in the "valley" between threads, meaning the only thing holding your project together is luck and gravity.

Materials and the "Sacrificial" Reality

Honestly, the chemistry of your screws matters more than the shape. We see this all the time in coastal regions or high-humidity environments. You buy some zinc-plated sheet metal self tapping screws because they’re cheap. Six months later, the screw is fine, but the metal around it has disintegrated into a powdery white mess. This is galvanic corrosion.

When two dissimilar metals touch in the presence of moisture, they create a tiny battery. One metal becomes the anode and starts to dissolve. If you put a stainless steel screw into aluminum siding without a buffer, the aluminum is going to lose that fight every single time.

✨ Don't miss: Project Liberty Explained: Why Frank McCourt Wants to Buy TikTok and Fix the Internet

Stainless Steel Isn't Always the Hero

A lot of "experts" will tell you to just use stainless steel for everything. That's lazy advice. While 304 or 316 grade stainless is amazing for corrosion resistance, it's significantly softer than heat-treated carbon steel. If you're driving into a harder alloy, a stainless screw will often "gall"—the threads literally weld themselves to the hole mid-turn due to friction heat—and the screw snaps.

For high-stress or heavy-duty industrial applications, many pros look toward specialized coatings like Ruspert or Magni. These aren't just "paint." They are multi-layer ceramic or zinc-aluminum coatings designed to handle 1,000+ hours of salt spray testing. If you’re building something that needs to last thirty years in the rain, skip the shiny zinc stuff from the bin and look for the dull grey, high-performance coatings.

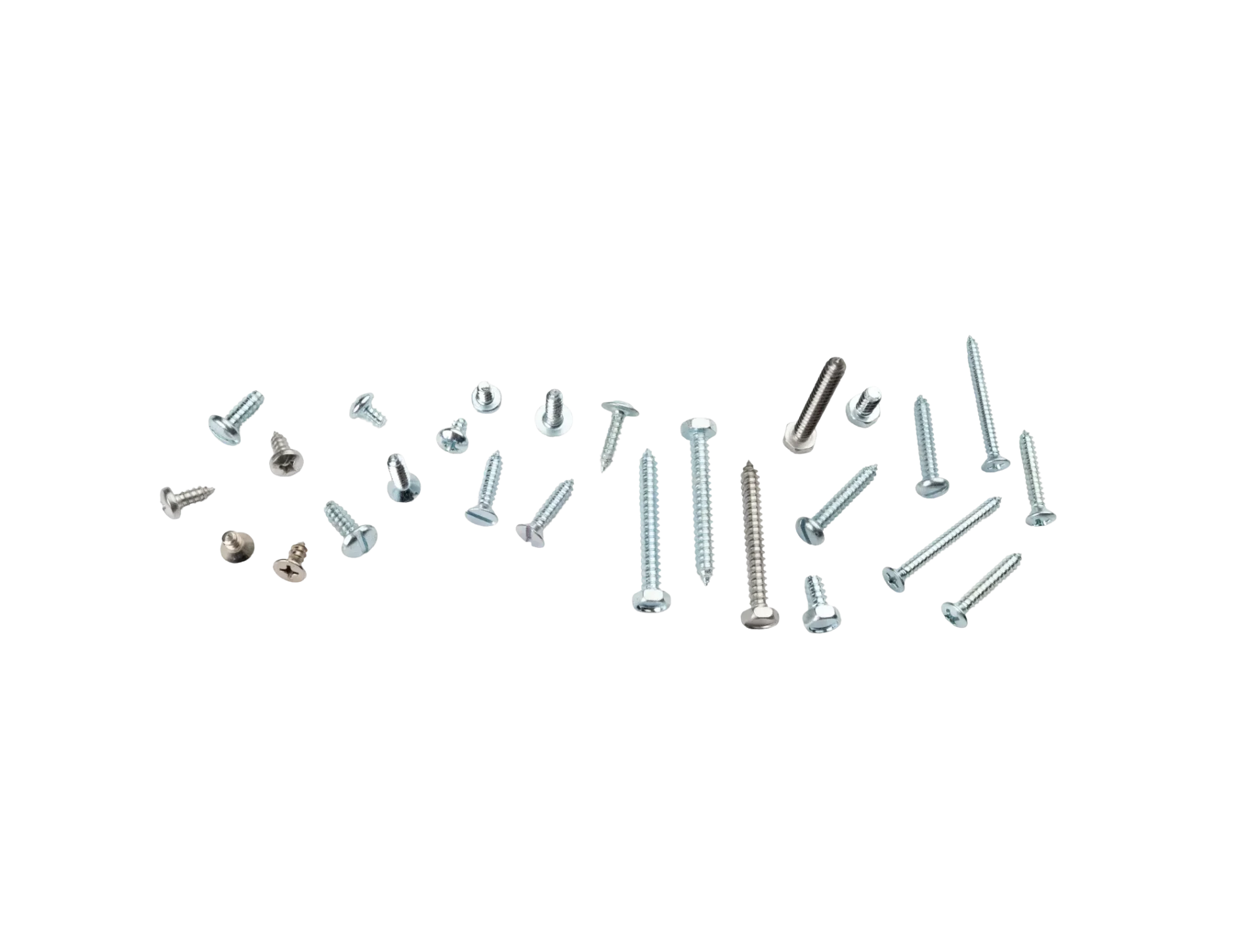

Head Styles: More Than Just Aesthetics

The "head" of the screw dictates how much torque you can apply and how the finished product looks.

- Pan Head: The workhorse. It sits on top of the metal with a slightly rounded profile. It’s the safest bet for general assembly.

- Flat/Countersunk: Only use these if the metal is thick enough to be "dimpled" or countersunk. If you try to use these on paper-thin flashing, the head will just distort the metal and look like garbage.

- Hex Washer Head: This is what you see on metal roofing and pole barns. The built-in washer distributes the pressure, preventing the screw from pulling through the sheet in high winds.

- Truss Head: These have an extra-wide, low-profile top. They are perfect for when you need a lot of surface area to hold down a thin membrane or mesh but don't want a huge bump sticking out.

Drive types are a whole other battle. Phillips head is the most common, but it's also the worst for high-torque applications because it's designed to "cam out" (the bit slips out of the screw) to prevent over-tightening. In a modern shop, you really should be moving toward Robertson (Square) or Torx (Star) drives. They don't slip. You can drive them one-handed while hanging off a ladder, which is a massive quality-of-life upgrade.

Why Gauge Matters (And Why You're Stripping Threads)

Sheet metal thickness is measured in gauges. The higher the number, the thinner the metal. It’s counter-intuitive, I know. 24-gauge is thin; 10-gauge is thick.

If you're using #8 sheet metal self tapping screws, you need to match your pilot hole to the specific gauge of the metal. If the hole is 0.005 inches too big, the screw will spin freely. If it’s too small, the torque required to turn the screw will exceed the breaking strength of the steel shank.

🔗 Read more: Play Video Live Viral: Why Your Streams Keep Flopping and How to Fix It

There’s a concept called "strip-to-drive ratio." You want a screw that requires very little effort to start but a lot of effort to strip out. Achieving this balance in thin materials is why some screws have "twin-lead" threads (two threads running parallel) or "high-low" threads. The high-low pattern features a tall, sharp thread and a shorter, secondary thread. This configuration grabs more material and is a lifesaver when you're working with plastics or very soft, thin metals that tend to crumble under pressure.

Real-World Failures: The HVAC Nightmare

Ask any veteran HVAC tech about "zips." These are the small, needle-point sheet metal screws used to join ductwork. They’re usually 1/2 inch long with a 1/4 inch hex head.

The most common failure isn't the screw breaking; it's the installer over-driving them. With high-torque impact drivers, it is incredibly easy to "strip the hole" in a fraction of a second. Once that metal is stripped, the screw provides zero structural integrity. It’s just a plug. In a vibrating environment like a furnace plenum, that stripped screw will eventually back out, the duct will sag, and your efficiency drops through the floor.

Pro Tip: If you strip a hole, don't just try to cram a bigger screw in there. Move two inches over and start fresh, or use a "backup" like a pop rivet if you absolutely need that specific spot secured.

Buying Guide: What to Look For

When you're sourcing sheet metal self tapping screws for a serious project, ignore the generic "assortment kits" on discount sites. They are often made from inferior "pot metal" that lacks proper heat treatment. Look for:

- Case Hardening: The surface of the screw should be hard enough to cut metal, but the core should remain slightly ductile so it doesn't snap under lateral stress.

- Point Geometry: For self-drilling types, ensure the "flutes" (the grooves on the tip) are long enough to clear the metal shavings. If the metal is thicker than the flutes, the shavings get trapped, the tip gets cherry-red hot, and it stops drilling.

- Standards Compliance: Look for marks of quality control like SAE J933 or specific ASTM standards. This ensures the steel is actually what the box says it is.

Putting It Into Practice

Don't just grab a handful of screws and start blasting. If you want a professional result that doesn't rust out or fall apart, follow a simple workflow.

💡 You might also like: Pi Coin Price in USD: Why Most Predictions Are Completely Wrong

First, determine your total material thickness. This includes any gaps between the sheets. Your screw needs to be long enough so that at least three full threads extend past the back of the material. If the "taper" of the screw tip is all that's sitting in the metal, it won't hold.

Second, check your environment. If you're within 15 miles of the ocean, you need 304 stainless steel or better. Period. If you're indoors in a dry room, standard zinc is fine.

Third, match your tool to the job. Stop using a 12v drill-driver for everything. For heavy-duty self-drilling screws, you need consistent RPM and pressure. For delicate tapping into thin aluminum, you need a clutch setting so low that it stops the moment the head touches the surface.

Next Steps for Your Project:

- Check the gauge of your metal using a standard wire/metal gauge tool.

- If using self-tapping (non-drilling) screws, consult a drill bit chart to find the exact decimal equivalent for your pilot hole.

- Inspect your driver bits; a worn Phillips bit is the #1 cause of "stripped" screw heads, which are a nightmare to remove once they're halfway in.

- Test one screw on a scrap piece of the same material to calibrate your drill's clutch before touching the actual workpiece.

By paying attention to the "boring" details of thread pitch, metallurgy, and hole diameter, you move from "doing DIY" to actually engineering a solution. It sounds overkill for a screw, but anyone who has had to back out a rusted-solid, stripped-head fastener at the top of a ladder knows exactly why this matters.