Honestly, you’ve probably never held a piece of pure scandium in your hand. Most people haven't. It’s one of those elements hiding in plain sight, tucked away in the periodic table between calcium and titanium, yet it is currently driving some of the most sophisticated engineering on the planet. For decades, it was a "boutique" metal—something scientists thought was cool but way too expensive to actually use.

That’s changing. Fast.

If you look at the tech landscape in 2026, scandium what is it used for isn't just a chemistry question; it’s a question about how we build the future of flight, clean energy, and even your favorite hobbies. It is the secret sauce that makes aluminum stop behaving like a soft metal and start acting like high-strength steel.

The Aerospace Power Move

In the world of aviation, weight is the enemy. Every extra gram requires more fuel, which means more money and more emissions. This is where scandium shines. When you add a tiny amount of scandium—we're talking maybe 0.1% to 0.5%—to aluminum, the results are kinda wild.

It creates an alloy that is incredibly strong but still light. More importantly, it solves aluminum's biggest "Achilles heel": welding. Traditional high-strength aluminum alloys are notoriously difficult to weld because they tend to crack when they cool down. Scandium prevents this by refining the grain structure of the metal.

Because of this, companies like Airbus have been experimenting with Scalmalloy, a scandium-aluminum powder designed specifically for 3D printing aircraft parts. Instead of milling a part out of a giant block of metal (and wasting 80% of it), they can print complex, organic shapes that are lighter and stronger than anything we’ve seen before.

Why Your Sports Gear Costs More

You’ve likely seen the word "Scandium" etched onto the side of a high-end mountain bike frame or a professional-grade lacrosse stick. It’s not just marketing fluff.

In sports equipment, the "strength-to-weight ratio" is everything. A scandium-alloy bicycle frame can be roughly 12% lighter and 50% stronger than a standard aluminum one. For a pro athlete, that's the difference between a podium finish and a "thanks for coming."

- Baseball Bats: Scandium allows for thinner walls in the "sweet spot," giving the bat more "pop" without making it heavy.

- Revolvers: Companies like Smith & Wesson use scandium in their "AirLite" series. It allows them to build a .357 Magnum that weighs next to nothing but doesn't explode when you pull the trigger.

- Tent Poles: High-end mountaineering gear uses scandium to ensure poles don't snap under heavy snow loads while remaining light enough to carry up Everest.

The Green Energy Secret: Solid Oxide Fuel Cells

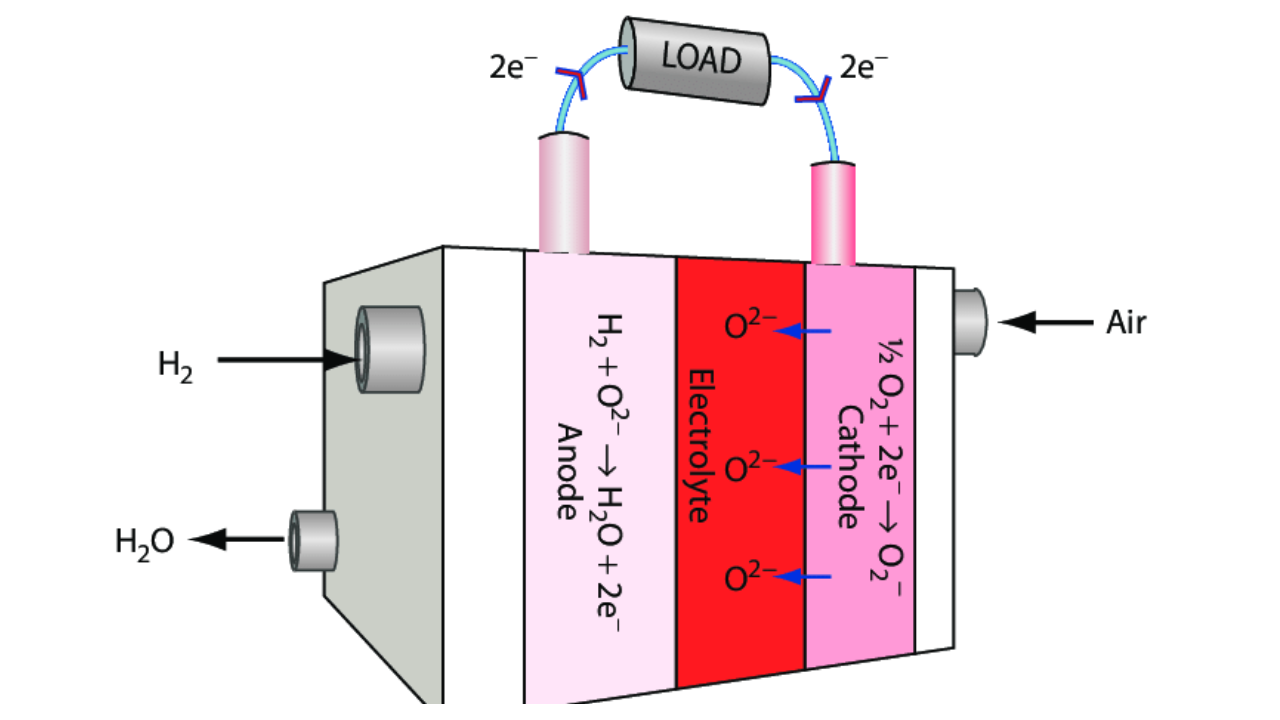

This is where things get really interesting and a bit more technical. Beyond just making things "strong and light," scandium is a hero in the world of Solid Oxide Fuel Cells (SOFCs).

These fuel cells are basically big batteries that run on natural gas or hydrogen to create electricity with very low emissions. The problem? They usually have to run at blistering temperatures—think $1,000^{\circ}C$—to work. That heat destroys the components over time.

By using scandium-stabilized zirconia as an electrolyte, engineers can drop the operating temperature down to around $600^{\circ}C$ or $800^{\circ}C$. This might still sound hot, but for a machine, it’s the difference between a long, healthy life and a quick trip to the scrap yard. It makes the systems cheaper, more durable, and finally viable for powering data centers or even remote neighborhoods.

Where Does It Actually Come From?

Here is the catch: scandium is everywhere, but it’s nowhere. It’s more abundant in the Earth’s crust than lead, but it rarely bunches up into "ore" that’s easy to mine.

Historically, we’ve relied on byproduct recovery. When people mine for titanium or uranium, they sometimes find bits of scandium left over in the waste (often called "red mud"). Most of the world’s supply has traditionally come from China and Russia, which has made Western manufacturers very nervous lately.

However, as of 2026, we’re seeing a massive shift. New primary mines are coming online in places like New South Wales, Australia (the Syerston Project) and Quebec, Canada (the Crater Lake project). These aren't just byproducts anymore; companies are digging specifically for the scandium.

📖 Related: The 2012 Solar Flare: Why Earth Almost Had a Very Bad Day

What Most People Get Wrong

There’s a common misconception that scandium is a "Rare Earth Element" because it’s hard to find. Technically, it is classified as a rare earth, but it doesn't behave like the others (like Neodymium or Lanthanum).

Another myth is that it’s too expensive for "normal" stuff. While it still costs a few thousand dollars per kilogram for the oxide, the amount used in an alloy is so small that the price-per-part is actually starting to make sense for high-end electric vehicles (EVs). By reducing the weight of an EV frame, you can use a smaller, cheaper battery and get the same range.

Actionable Steps for 2026

If you're an engineer, investor, or just a tech nerd, here is how you should be looking at scandium right now:

- Watch the Supply Chain: Keep an eye on the NioCorp project in Nebraska or Sunrise Energy Metals in Australia. If these projects hit their production targets, the "scarcity" of scandium could vanish, leading to a surge in consumer applications.

- Evaluate 3D Printing: If you are in manufacturing, look into AlSc powders. The ability to 3D print structural parts that don't require heat treatment is a massive time-saver.

- Check Your Labels: Next time you buy high-end gear—whether it’s a fly-fishing rod or a drone—check the materials list. If it says "Sc-Al," you're holding some of the most advanced metallurgy available today.

The reality is that we are moving toward a world where "heavy" is a choice. Scandium is the tool that lets us choose "light and strong" instead.

Next Steps: You should investigate the current export restrictions from major producers, as these are driving the price volatility seen in early 2026. Reviewing the latest technical specs for Scalmalloy will also give you a better idea of how 3D printing is utilizing this metal in the aerospace sector.