That roar. It starts as a subtle hum during the spin cycle, maybe a faint metallic rhythmic chirping that you ignore for a month. Then, suddenly, your laundry room sounds like a Boeing 747 is taking off inside your house. If you own a Samsung front loader, you probably already know what’s coming. It’s the bearings. Honestly, it's the Achilles' heel of these otherwise sleek machines.

When the tub bearings fail, it’s not just a noise issue. It is a mechanical catastrophe waiting to happen. If you catch it early, you might save the machine. Wait too long? The inner tub spider arm snaps, the plastic outer tub gets gouged by the spinning metal, and you’re looking at a $600 repair bill for a $800 washer. At that point, most people just go to the big box store and buy a new one. But you don't have to. A Samsung front load washer bearing replacement is a grueling, five-hour weekend project, but it’s entirely doable for someone with a socket wrench and some patience.

The Brutal Reality of Why These Bearings Die

Samsung machines are engineered for efficiency, but the bearing design is somewhat traditional—and prone to a specific type of failure. Inside the rear half of the outer tub, there are two sealed ball bearings and a large rubber seal. The seal is the gatekeeper. Its job is to keep the soapy, caustic water away from the steel bearings.

Over time, two things happen. First, the use of too much detergent (specifically non-HE or just way too much HE soap) creates "scrubbing" action that wears down the rubber lip of the seal. Second, the "Spider Arm" (the three-pronged aluminum bracket that holds the drum) begins to corrode. This is a process called galvanic corrosion. The aluminum spider reacts with the stainless steel drum and the minerals in your water. It turns into a white, powdery mush. This crusty buildup eventually tears the bearing seal. Once water touches those steel balls, they rust. Then they heat up. Then they scream.

How to know if it's actually the bearings

Before you tear your entire house apart, do the "shake test." Open the door. Reach in and grab the top of the stainless steel inner drum. Try to wiggle it up and down independently of the outer plastic tub. If it clicks, thumps, or moves even a quarter-inch without the outer tub moving with it, your bearings or your spider arm are toast.

Another sign? Look for "black grease" or rusty streaks on the back of the machine or on your clothes. That’s the liquefied remains of your bearing grease leaking out because the seal has failed. It’s messy. It’s gross. It’s a definitive diagnosis.

Preparation: More Than Just a Screwdriver

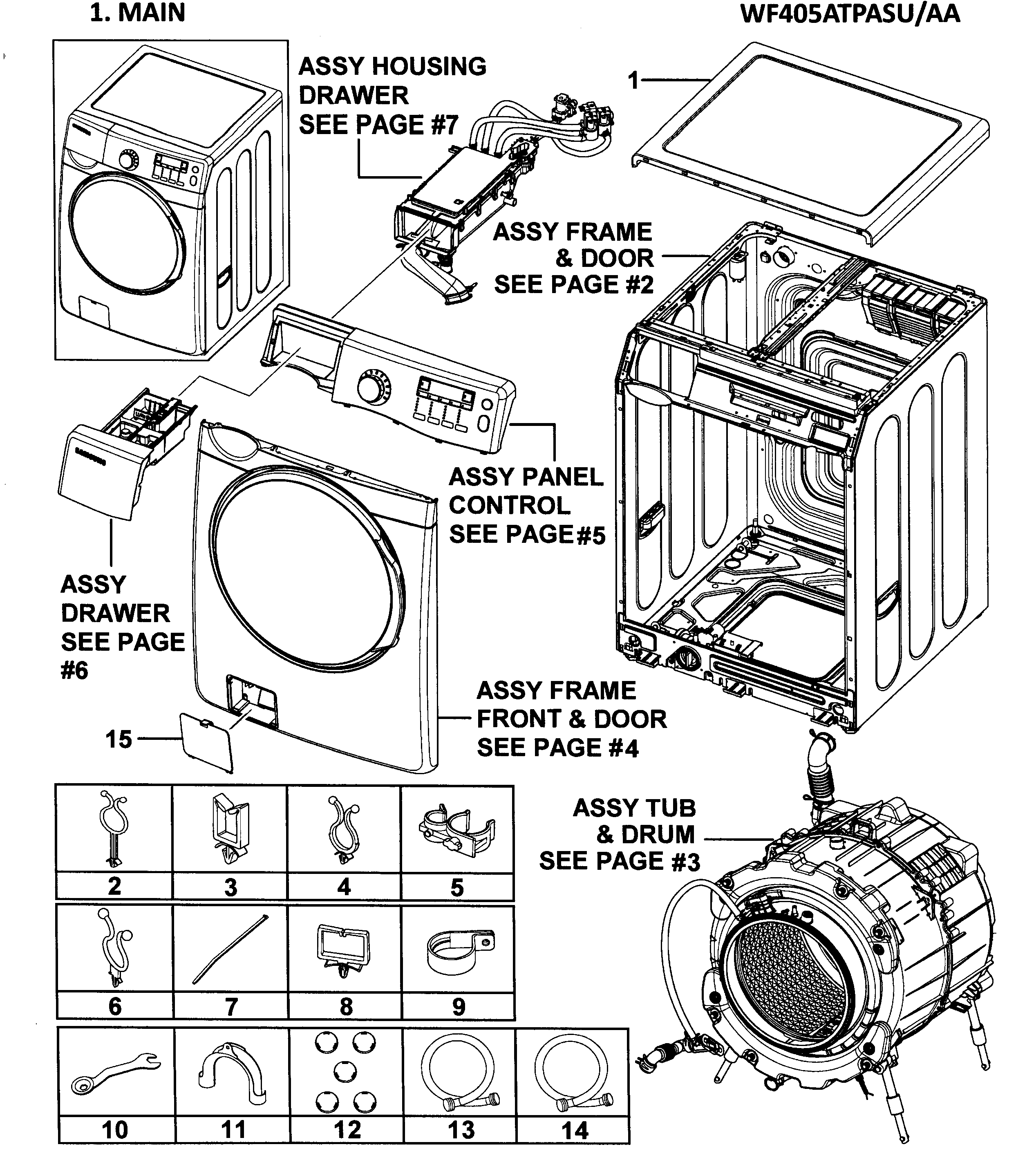

You’re going to need a lot of floor space. Seriously. You have to take almost every single part out of the cabinet to get to the tub. I’m talking the control panel, the detergent drawer, the door boot, the weights, and finally the tub itself.

👉 See also: Clothes hampers with lids: Why your laundry room setup is probably failing you

Tools you absolutely need:

- A full socket set (10mm, 12mm, 13mm, and a big 19mm for the rotor bolt).

- A Phillips head screwdriver (a magnetic tip is a lifesaver here).

- A heavy hammer or a small sledgehammer (for "persuading" the shaft out).

- A block of wood (to protect the shaft while you hit it).

- High-temp waterproof grease (Marine grease works best).

- The replacement kit: This usually includes the large bearing, the small bearing, and the tub seal.

Don't buy the cheapest bearings you find on a random auction site. Look for high-quality brands like SKF or NSK. If you're going through all the trouble of a Samsung front load washer bearing replacement, you don't want to do it again in six months because a $5 bearing failed.

The Teardown: A Descent into Madness

Start by unplugging the thing. Water off, too. You'll remove the top panel first, usually held by two screws at the back. Once the top is off, you start to see the complexity. The logic board is there, the pressure switch is there. Take photos. Lots of them. You think you’ll remember where that blue wire goes, but you won't.

The hardest part for most people is the door boot seal spring. There’s a wire hoop holding the rubber gasket to the front frame. You need to stretch that spring to get it off. Some people use needle-nose pliers; others buy a specific spring expansion tool. Honestly? You can do it with two sturdy screwdrivers and a bit of swearing.

Extracting the Tub

Once the front hum of the machine is gone, you’re left with the "heart." The tub is suspended by springs and held steady by shock absorbers at the bottom. Disconnect the heater wires, the motor wires, and the drain bellows.

When you lift that tub out, it’s heavy. Those concrete counterweights are no joke. Pro tip: Remove the weights while the tub is still in the machine. Your back will thank you. If you leave them on, the tub assembly weighs about 80 pounds and is incredibly awkward to maneuver.

✨ Don't miss: Christmas Treat Bag Ideas That Actually Look Good (And Won't Break Your Budget)

Splitting the Atom (Or Just the Tub)

The outer tub is held together by about 15 to 20 bolts around the perimeter. Zip those off with a drill. When you pull the two halves apart, you’ll see the inner drum. This is the moment of truth. Pull the inner drum out of the rear tub half.

If the drum won't budge, it's because the shaft is seized to the bearings. This is where the block of wood and the sledgehammer come in. Bolt the 19mm rotor bolt back into the shaft a few threads so you don't mushroom the end of the shaft, place the wood over it, and give it a solid "Standardized Metric Thump." It will eventually pop through.

Inspecting the Spider Arm

Look at the three-pronged aluminum arm on the back of the metal drum. Is it covered in grey sludge? Is one of the arms cracked? If the spider arm is failing, replacing the bearings won't fix your noise. The drum will still be off-balance. Most pros recommend replacing the spider arm anyway while you're in there. It’s another $60-$100, but it’s cheap insurance.

Removing the Old Bearings

This is the "fun" part. You’ll see the rubber seal, then the outer bearing, then a spacer, then the inner bearing. Use a long punch or a heavy-duty flathead screwdriver. Reach through from the opposite side and tap the bearing race. Move in a circle—12 o'clock, 6 o'clock, 3 o'clock, 9 o'clock. You want it to come out straight.

Once they are out, clean the housing. Any bit of grit or old rust will prevent the new bearings from seating properly. If the housing is pitted or cracked, the tub is dead. But usually, a good scrub with some steel wool gets it shiny again.

Reassembly: The Golden Rule of Grease

When you tap the new bearings in, only hit the outer race. If you hit the inner part of the bearing, you’ll dent the ball bearings and they’ll fail instantly. Use a large socket that matches the diameter of the bearing's outer ring to drive it home.

🔗 Read more: Charlie Gunn Lynnville Indiana: What Really Happened at the Family Restaurant

The seal is the most important part. Pack the inside of the seal—the "V" groove—with your waterproof grease. Be generous. This grease is the secondary line of defense against water. If the seal stays lubricated, it won't friction-burn against the shaft, and your repair will last a decade.

Slide the drum back in. It should spin silently. Like, eerie silent. If it feels crunchy, something is wrong. Stop and check.

Putting the Puzzle Back Together

Reverse the teardown. Reattach the shocks, hang the tub, reconnect the wiring. Pay close attention to the heating element. If you didn't seat it into its bracket inside the tub, the spinning drum will hit it and create a horrible grinding sound (and a fire hazard).

Before you put the front panel on, do a quick "hand spin" of the drum. Listen for any rubbing.

Actionable Insights for Longevity

You just spent five hours and probably $150 on parts. You don't want to do this again. To keep your new Samsung front load washer bearing replacement from becoming a biennial tradition, change how you do laundry:

- Stop using so much soap. A tablespoon of HE detergent is plenty for a normal load. If you see suds during the rinse cycle, you used too much.

- Run a "Self Clean" cycle once a month. Use a dedicated tub cleaner or a cup of bleach. This eats the biofilm that causes the spider arm to corrode.

- Leave the door open. Seriously. Every time you finish a load, leave that door cracked. It lets the moisture evaporate from the seal and prevents the "sludge" that eats aluminum.

- Check your loads. Don't wash one heavy rug by itself. The machine will struggle to balance it, putting immense lateral pressure on the bearings. Always wash rugs in pairs or with towels to distribute the weight.

If you’ve finished the job and the machine is whisper quiet, congratulations. You just saved a $400 labor bill and kept a massive piece of steel and plastic out of the landfill. It’s a tough repair, honestly one of the hardest in the appliance world, but the satisfaction of that first silent spin cycle is worth every scraped knuckle.

Next Steps:

Identify your specific model number on the sticker inside the door frame. Order a bearing kit that specifically includes the "high-performance" seal and the tub gasket. If your machine is more than five years old, order the spider arm (flange) assembly as well; 90% of the time, it needs replacing once you get inside.