You’re staring at a pile of pressure-treated 4x4s and a roll of cedar pickets. Your back already hurts just thinking about the post-hole digger. This is exactly where the temptation of post spikes for fence installation creeps in. It sounds like a dream, right? No mixing heavy bags of Quikrete. No hauling away buckets of grey, sludge-like clay. Just grab a sledgehammer, smash a piece of steel into the dirt, and call it a day. Honestly, it sounds too good to be true because, in many cases, it absolutely is. But if you know what you’re doing, these things can save your weekend.

The reality of fence building has changed. We aren't all living on flat, loamy plains where every post can be buried four feet deep. Sometimes you’re dealing with aggressive tree roots, buried utility lines that make you nervous, or a landlord who told you that "permanent structures" are a no-go. That is where the metal spike—often called a "bolt-down" or "drive-in" anchor—enters the chat.

But don't go buying a 20-pack from Home Depot just yet. There’s a massive difference between the Simpson Strong-Tie versions and the generic stuff you find on discount sites. If you pick the wrong one, or put it in the wrong soil, your fence will be leaning like the Tower of Pisa by next April.

The Brutal Truth About Soil and Post Spikes for Fence Stability

Soil isn't just "dirt." It’s an engineered substrate, at least in the eyes of a structural engineer. If you’re trying to use post spikes for fence support in loose, sandy soil, you're basically wasting your money. Sand has zero lateral resistance. Think about it. You push the spike in, it feels tight, but the moment a 40-mph wind gust hits that "sail" we call a fence panel, the sand just shifts. The spike stays in the ground, but it tilts. And once a spike tilts, it’s nearly impossible to knock it back into a true vertical position without pulling the whole thing out.

Clay is different. Hard-packed clay is the best friend of a fence spike. It grips the fins of the metal like a vice. If you have that thick, red or grey clay that’s a nightmare to dig? That’s actually where a spike shines.

You've got to consider the "heave." In places like Minnesota or Ontario, the freeze-thaw cycle is a beast. Water gets under the spike, freezes, expands, and pushes the metal upward. This is "frost heave." Traditional concrete footings are supposed to go below the frost line—often 36 to 48 inches deep—to prevent this. Most spikes are only 24 to 30 inches long. Do the math. If you live in a deep-freeze zone, your spiked fence is going to dance every winter. It’s not a matter of if; it’s a matter of when.

Why the "Short Cut" Often Takes Longer

People think spikes are fast. They can be. But have you ever tried to drive a 30-inch piece of galvanized steel into a ground full of rocks? You hit one rock—just one—and the spike turns. Now your square post base is sitting at a 15-degree angle. You can't just "twist" it back. You have to pull it out, which is a Herculean task, and try again four inches to the left.

💡 You might also like: Easy recipes dinner for two: Why you are probably overcomplicating date night

I’ve seen DIYers spend six hours trying to get four spikes level. In that same time, they could have rented a power auger and poured concrete.

Material Matters: Galvanized vs. Powder Coated

If you’re going to do this, look at the finish. You’ll see two main types:

- Hot-dipped galvanized: This is the gold standard. It’s ugly, dull grey, and looks industrial. But it won't rust for 30 years.

- Black powder-coated: It looks "premium" and sleek. It’s not. The moment you hit that spike with a sledgehammer, the coating chips. Moisture gets under the paint. Within two seasons, the base is bleeding orange rust onto your nice white vinyl or cedar.

Always use a "driving tool"—a small block of wood or a specialized plastic insert—between your hammer and the metal. If you smash the metal rim directly, you’ll deform the box where the post is supposed to sit. Then you’re out there with a file trying to shave down a 4x4 just to make it fit. It’s a mess.

Let’s Talk About Wind Load

A standard 6-foot privacy fence is effectively a giant sail. If you live in a coastal area or a flat windy plain, post spikes for fence are risky. The leverage exerted on a 6-foot post is immense. The "pivot point" is right at the ground level where the spike meets the post.

Most spikes use a "pinch bolt" system to hold the wood. Over time, as the wind rocks the fence back and forth, the wood fibers compress. The post starts to wiggle. Once the wiggle starts, it’s a death spiral for the fence’s structural integrity. You’ll find yourself out there every few months tightening bolts until the wood eventually cracks.

For a 3-foot garden picket fence? Spikes are amazing. For a 6-foot solid cedar privacy wall? You're playing a dangerous game with physics.

📖 Related: How is gum made? The sticky truth about what you are actually chewing

When Spikes Actually Make Total Sense

It's not all doom and gloom. There are scenarios where spikes are the superior choice.

Temporary fencing is the obvious one. Maybe you have a puppy that needs a run for six months while you’re renovating the main yard. Or maybe you're testing out a layout before committing to a $10,000 professional install. Spikes allow you to change your mind.

They are also great for "no-dig" zones. If you have a high concentration of shallow utilities (always call 811 first!), a spike is sometimes safer than a spinning power auger that can catch a line and rip it out. You can feel the resistance of a pipe with a manual sledgehammer much better than you can with a gas-powered drill.

The Hybrid Approach

Some pros use a hybrid method. They use spikes for the "line posts" (the ones in the middle) but they always, always set the "gate posts" and "corner posts" in deep concrete. This is a smart compromise. The corners and gates take all the tension and movement. If a line post wiggles a bit, the fence stays up. If a gate post wiggles, the gate won't latch.

The Money Question

Spikes are expensive. A decent heavy-duty 4x4 spike will run you $25 to $40. A bag of concrete is $6. Even with the cost of a rental auger, concrete is usually cheaper for a large project. You aren't paying for the materials when you buy spikes; you're paying for the "convenience."

Is your time worth $30 per post? For some, absolutely. If you only have a few hours on a Saturday and just need to fix a leaning section, the spike is a lifesaver.

👉 See also: Curtain Bangs on Fine Hair: Why Yours Probably Look Flat and How to Fix It

Actionable Steps for a Spike-Driven Fence

If you’ve decided that post spikes for fence are the way to go for your specific project, don't just wing it. Follow these steps to ensure you aren't rebuilding the thing next year.

1. The "Probe" Test

Before you buy a single spike, take a long, thin screwdriver or a piece of rebar and shove it into the ground where every post will go. If you hit rocks at 12 inches deep in three different spots, stop. Spikes won't work there. You’ll end up with a crooked fence and a bruised ego.

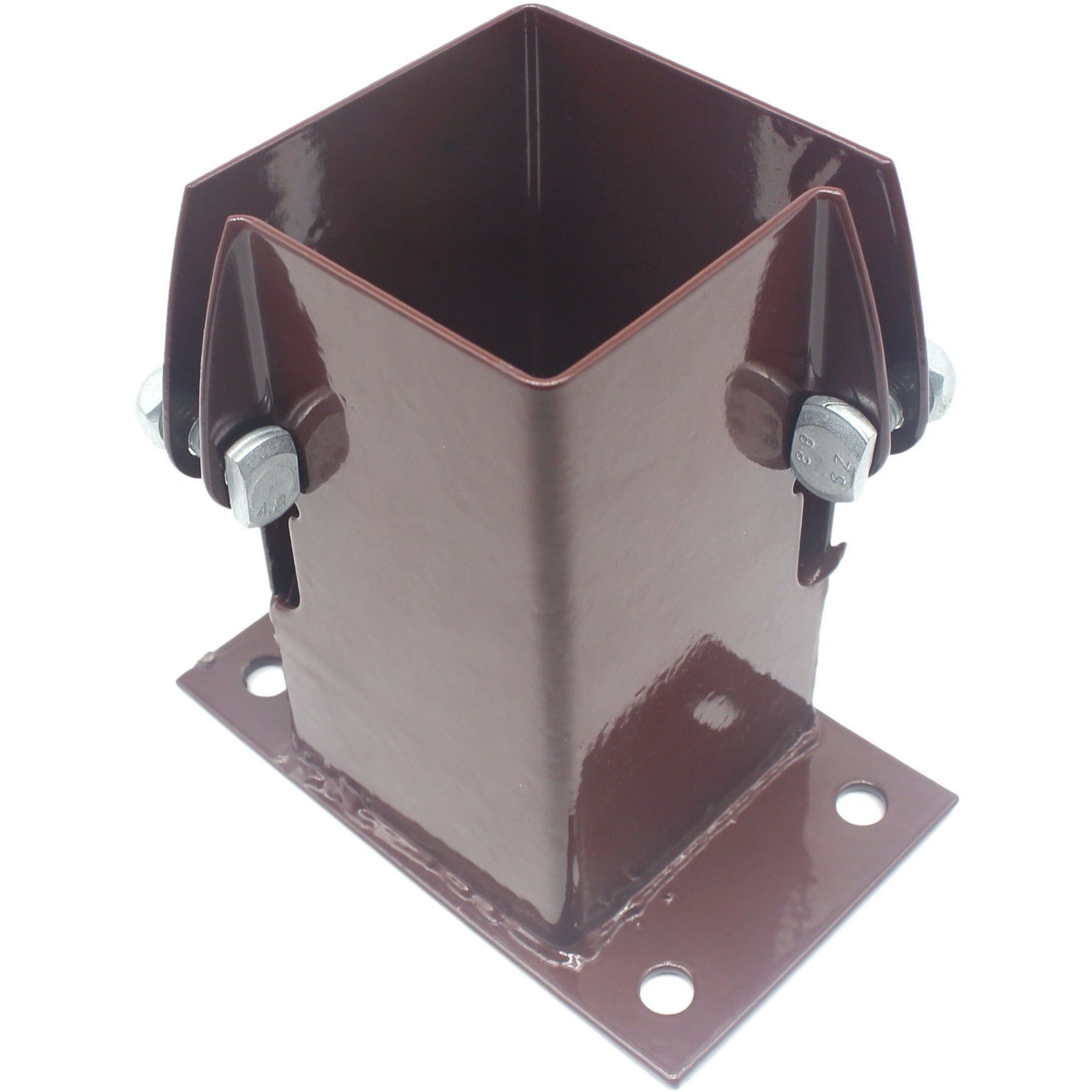

2. Buy the "Box" Style, Not the "U" Style

You will see some anchors that are just a U-shaped piece of metal. Avoid them. They have zero lateral stability. You want the full square box that the 4x4 slides into. It grips the wood on all four sides. It’s worth the extra five bucks.

3. Use the Right Fasteners

Don't use standard wood screws to attach the post to the spike. Use 1/2-inch galvanized carriage bolts or heavy-duty structural screws like GRKs. The shearing force on those points is high. Cheap screws will literally snap off when the wind hits the fence.

4. Check Level Every Five Hits

Don't just drive the spike all the way in and then check if it's straight. Drive it 6 inches. Check level. Drive another 6 inches. Check again. If it starts to go crooked, you can still correct it by hitting the side of the spike. Once it's 20 inches deep, it's set in its ways.

5. Drainage is Key

One of the biggest killers of spiked fences is "butt rot." Water gets trapped inside the metal box where the wood sits. Make sure your spike has a drainage hole at the bottom. Before you slide the post in, coat the bottom 6 inches of the wood in a copper-naphthenate preservative or a bit of roof flashing cement. This keeps the wood from sitting in a puddle every time it rains.

6. Mind the Height

Keep the top of the metal "box" about an inch above the soil. If you bury the metal sleeve entirely, you’re inviting moisture and termites to feast on your posts. Seeing a little bit of the metal isn't the prettiest look, but it's the difference between a 2-year fence and a 10-year fence.

Building a fence is a rite of passage for homeowners. It’s one of those projects that looks easy on YouTube but reveals its complexity the moment you hit the first tree root. Post spikes for fence construction are a tool in the toolbox—nothing more, nothing less. They aren't a "cheat code" that works in every backyard. Use them for garden borders, mailboxes, or light-duty screening in heavy clay soil. If you’re trying to keep a 100-pound German Shepherd inside a 6-foot privacy enclosure in a windy corridor, get the shovel and start mixing the concrete. Your future self will thank you when you aren't out there in a rainstorm trying to prop up a falling fence with a 2x4.