If you’ve ever stood on a shivering ladder in mid-November staring at a standing seam metal roof, you know the specific brand of frustration I’m talking about. You bought the standard plastic clips from the big-box store. You tried to slide them under the metal edge. They snapped. Or worse, they just slid right off because metal isn't shingles. Metal is slippery, unforgiving, and, frankly, kind of a pain to decorate if you don't have the right hardware. Finding the right metal roof clips for christmas lights isn't just about making the house look pretty; it's about not having to climb back up there during a sleet storm to fix a sagging strand of C9s.

Metal roofs are skyrocketing in popularity because they last forever. But the "forever" part of a metal roof comes with a catch: you can’t exactly go hammering nails into it. You can't staple into it. Even those "all-in-one" clips designed for asphalt shingles usually fail because the "drip edge" on a metal roof is shaped differently. Most people think they can just use magnets and call it a day. Honestly? Magnets are cool until a 30-mph gust of wind turns your expensive LED display into a chaotic whip.

The Reality of Magnetic Clips vs. Mechanical Grips

Let's talk about magnets for a second because they are the first thing everyone searches for when they get a steel roof. Companies like Minleon or Apex make some seriously strong magnetic clips. If you have a true steel roof, magnets are a dream. They snap on, they stay put in light breezes, and they make takedown a three-minute job. But here is the catch that many homeowners miss: not all metal roofs are magnetic. If you have an aluminum roof or certain types of high-end copper or zinc, a magnet is basically a paperweight.

You need to test your roof with a kitchen magnet before you spend $200 on specialized magnetic clips. Even if your roof is steel, the thickness of the paint or the "texture" of the powder coating can weaken the magnetic bond. This is where mechanical metal roof clips for christmas lights come into play. These are usually made of heavy-duty plastic or spring steel and are designed to "bite" onto the standing seam or the gutter apron.

The "Standing Seam" clip is the gold standard for high-end metal roofs. These are specifically engineered to slide over the vertical rib of the roof. Unlike shingle clips, which rely on the weight of the shingle to stay down, these use tension. If you buy the cheap ones, they'll pop off the moment the plastic gets brittle in the cold. Look for clips made from UV-stabilized polycarbonate. It sounds fancy, but it basically just means the sun won't turn your clips into cracker-crumbs by December 25th.

Why Your Shingle Clips Are Useless Here

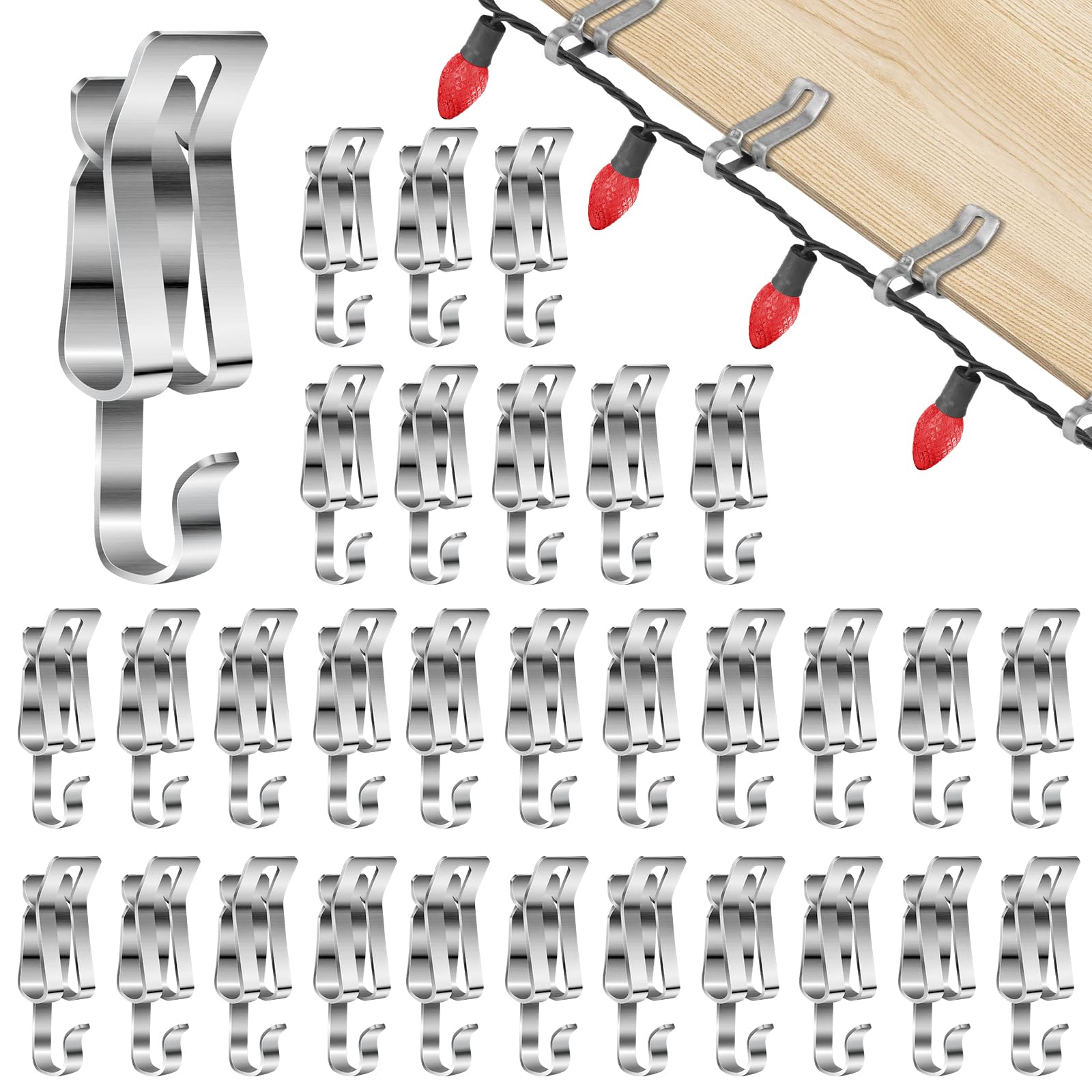

I've seen neighbors try to use the "S-hook" style clips on metal roofs. It never ends well. Metal roofs usually have a "hemmed" edge. This means the metal is folded back on itself at the gutter line to prevent sharp edges and provide strength. That fold is often too thick for a standard plastic shingle clip to grab onto. If you force it, you’ll see the plastic start to turn white—that's the material stressing. It’s going to fail.

📖 Related: Is there actually a legal age to stay home alone? What parents need to know

Instead, look for "Tuff Clips" or specialized "Bi-Way" clips. These are designed with a wider mouth that can actually accommodate the thickness of a hemmed metal edge. Some professional installers, the guys who charge $1,500 to do a house, swear by the "SimpleClip." It’s a low-profile option that grips the metal rib without scratching the Kynar finish. That's another thing: you have to be careful about scratching. If you use cheap metal-on-metal clips, you might scrape the protective coating off your roof, leading to rust spots five years down the line. That’s a very expensive way to celebrate the holidays.

Let's Talk About Gutter Apron Installations

Sometimes the roof itself isn't the best place for the lights. If your metal roof has a significant overhang, your best bet for metal roof clips for christmas lights might actually be a gutter-mount system. But wait. Metal roofs shed snow differently than shingle roofs. On a shingle roof, snow melts slowly and drips off. On a metal roof, the whole sheet of snow can slide off at once in what’s known as an "avalanche."

If your lights are clipped to the very edge of the metal or the gutter, a snow slide will rip them right off the house. This is why professional installers often mount lights slightly "up" the seam or use "snow guards" as anchors. If you live in a place like Minnesota or Buffalo, mounting your lights on the gutter apron under a metal roof is basically asking for a repair bill. You want clips that allow the lights to sit flush against the vertical face of the roof or tucked slightly under the eave.

The Professional Secret: Parapet Clips and Ridges

If you have a flat metal roof or a commercial-style building, you’re looking at parapet clips. These are heavy-duty clamps. But for the average homeowner, the trick is often the "Ridge Clip."

Most metal roofs have a ridge cap at the very top. There are specific clips designed to slide under that ridge cap. This allows you to run "peaks" of lights that go from the gutter up the seam to the ridge. It creates a much more architectural look than just a flat line along the gutters.

👉 See also: The Long Haired Russian Cat Explained: Why the Siberian is Basically a Living Legend

Material Matters

- Polycarbonate: Best for cold climates. It doesn't snap when it hits -10 degrees.

- Nylon: Okay, but tends to yellow and get brittle faster.

- Spring Steel: Great for permanent-style clips, but make sure they are powder-coated to prevent galvanic corrosion (when two different metals touch and cause rust).

How to Install Without Losing Your Mind

Start at the peak. Honestly. If you start at the bottom and work your way up, you’re always fighting the cord. If you use the right metal roof clips for christmas lights, you should be able to snap them onto the cord first, then slide them onto the seam.

Pro tip: don't over-stretch your lines. Metal expands and contracts with temperature changes. If you string your lights tight as a guitar string when it's 40 degrees, and then the temperature drops to zero, that wire is going to shrink. If there's no "give" in your clips, they will either pop off or the wire will snap. Leave a little bit of slack—not enough to look sloppy, but enough to breathe.

What Most People Get Wrong

People forget about the "drip edge." On a metal roof, the drip edge is often tucked so tight that you can't get a finger behind it, let alone a plastic clip. If this is your house, stop trying to force it. You'll just dent the metal. In these cases, you actually want to look for "Magnet-Mount" adapters that screw into the light socket itself.

Also, think about the wind. Metal is smooth. There is zero friction. On a shingle roof, the granules provide a bit of "grip" for the clip. On metal, it's like ice. If your clip doesn't have a "locking" mechanism or a very high-tension spring, the wind will eventually vibrate it until it slides down the seam. I’ve seen entire 50-foot runs of lights end up in a pile on the porch because the homeowner used "gravity-based" clips on a 12/12 pitch metal roof.

Practical Steps for a Stress-Free Display

First, grab a magnet. Go outside and see if it sticks to your roof. If it does, buy high-quality magnetic clips like the ones from Virdi or Christmas Designers. They are more expensive than the plastic junk, but you'll use them for ten years. If the magnet doesn't stick, you need standing seam clips.

✨ Don't miss: Why Every Mom and Daughter Photo You Take Actually Matters

Measure the width of your seams. Not all "standing seams" are the same width. Some are thin "pencil" seams; others are wide "snap-lock" seams. You need a clip that matches that width. If the clip is too wide, it’ll wobble. If it’s too narrow, you’ll break it trying to get it on.

Second, check your finish. If you have a matte finish or a "wrinkle" finish metal roof, adhesives (like those sticky-back clips) won't work. The texture prevents the glue from bonding. Stick to mechanical clips that "clinch" the metal.

Third, plan for the "Slide." If you live in a high-snow area, mount your lights on the vertical seams, not the horizontal eaves. When the snow slides off the roof, it will pass between the rows of lights rather than catching them like a net and tearing the whole system down.

Finally, buy 10% more clips than you think you need. You will drop some. You will break some. You will find one section of the roof that is inexplicably thicker than the rest. Having a handful of spares in your pocket saves you a trip down the ladder, which, when it's 25 degrees out, is the greatest gift you can give yourself.

Invest in UV-rated clips, verify your roof's magnetic properties before buying, and always prioritize clips that grip the vertical seams to avoid the inevitable "snow-slide" disaster common with metal roofing systems. High-quality hardware is the difference between a house that looks like a professional display and a house that has a "tangled mess" warning.